X-Ray drilling device

A technology of drilling device and drilling mechanism, which is applied to laser welding equipment, printed circuits, manufacturing tools, etc., can solve the problems of unfavorable high-precision alignment production, poor quality of punched hole shape, and inability to achieve punching, etc. The effect of improving drilling quality, improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

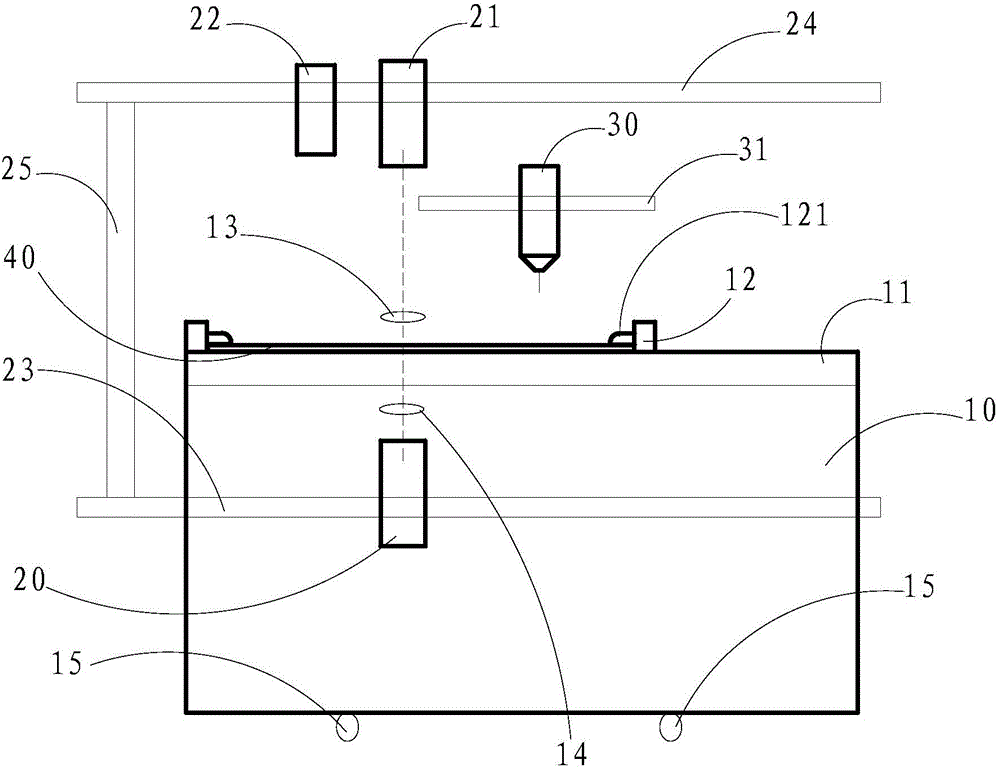

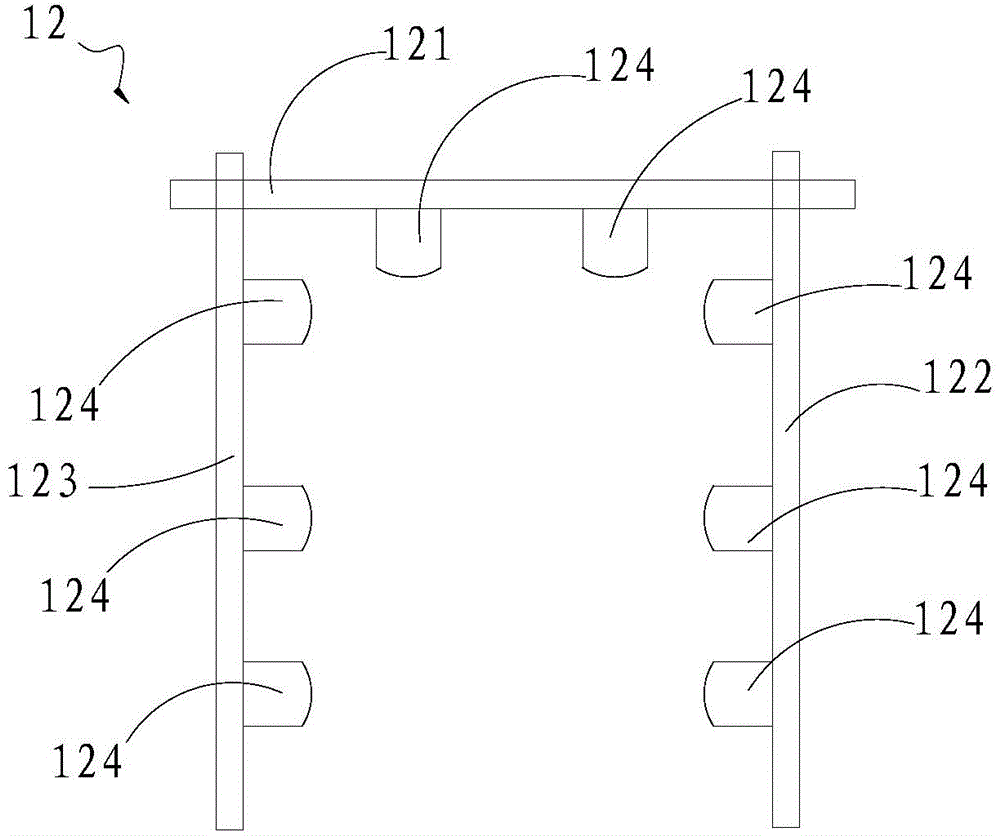

[0030] Such as figure 1 As shown, the X-Ray drilling device of the present invention includes a workbench 10, a first guide rail 15, a first drive mechanism (not shown in the figure), and the workbench 10 is connected with a The worktable 10 is connected to the first guide rail 15 , and the first driving mechanism is used to drive the workbench 10 to move along the first guide rail 15 .

[0031] The X-Ray drilling device of the present invention also includes a second drive mechanism (not shown in the figure), a second guide rail 23 and a third guide rail 24 arranged parallel to each other, the second guide rail 23, the third guide rail 24 Both have an included angle with the first guide rail 15 , and in the embodiment of the present invention, the second guide rail 23 and the third guide rail 24 are vertically arranged with the first guide rail 15 . And the second guide rail 23 is located below the first pressing structure 12, the third guide rail 24 is located above the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com