A column tray connecting device

A connecting device and tray technology, which is applied in the petroleum industry, hydrocarbon distillation, fractionation, etc., can solve the problems of insufficient clamping performance, small fastening force, and easy loosening, so as to improve positioning reliability and reduce the stress area , The effect of reasonable clamping structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

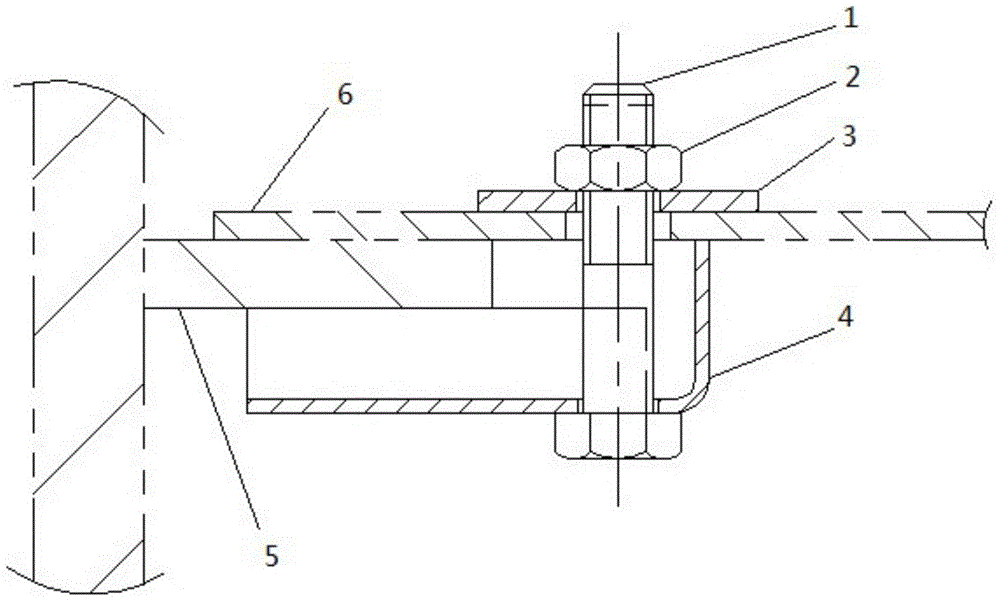

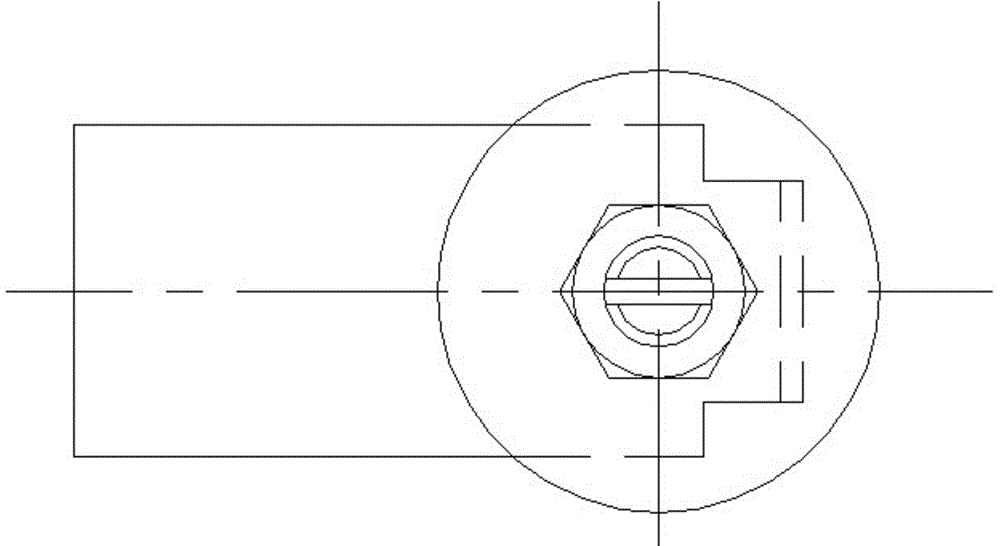

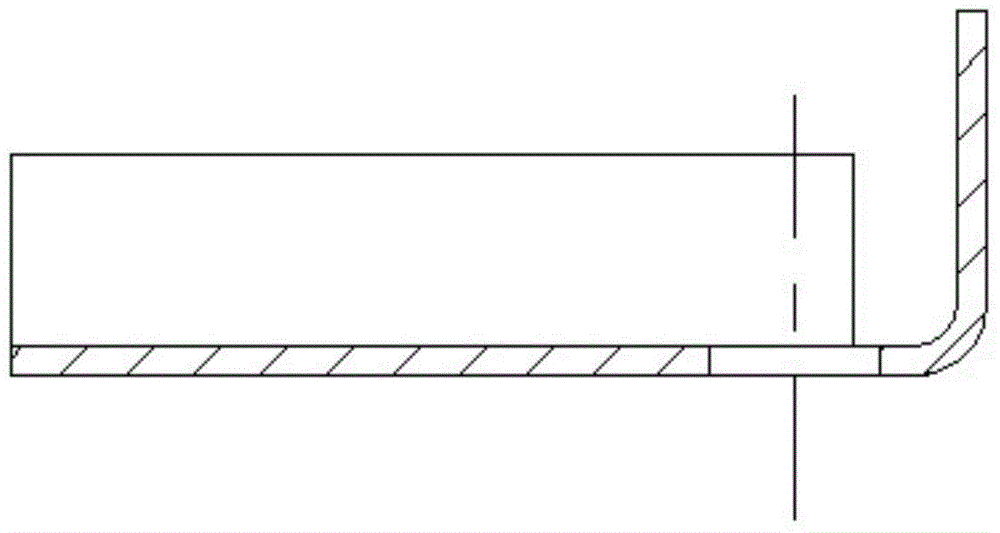

[0024] A tray connecting device, comprising a fastener arranged above the tray 6, and also includes a clamping plate 4 arranged below the tray 6, the clamping plate 4 is provided with a groove, and the groove is attached to the fastener Screw holes are provided on the lower surface of the clamping plate 4 corresponding to the fasteners, and the fasteners are fixed on the tray 6 through the bolts 1 passing through the screw holes and the nuts 2 .

Embodiment 2

[0026] A tray connecting device, similar to Embodiment 1, the difference is that a washer 3 is provided between the fastener and the nut 2; the fastener adopts a support ring 5; the side of the clamping plate 4 is set as L-shaped; the L-shaped bending part of the clamping plate 4 is provided with a round chamfer; the end surface of the groove is set as U-shaped; the bolt 1 is a headed bolt.

Embodiment 3

[0028] A tray connecting device is similar to Embodiment 1, except that it is equipped with a screwdriver; the screwdriver matches the type of the bolt 1; the number of the grooves is two.

[0029] A kind of tray connecting device of the present invention, it opens a hole on the tray 6, sticks on the lower surface of the support ring 5 with two grooves on the clamping plate 4, fastens the fastener with the nut 2 on the tray 6 Fixed on the tray 6, increasing the force of the bolt 1, the support ring 5 and the clamping plate 4 will be deformed at the contact position, which improves the fastening reliability. Remove the tray 6 from above, loosen the nut 2 above the washer 3, insert a screwdriver into the notch of the bolt 1, and rotate 90° to remove the tray 6 from above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com