Injection pen

An injection pen and refill technology, applied in the field of injection pen, can solve the problems of increased labor intensity, complex product structure, reduced injection accuracy, etc., and achieve the effects of protecting patient privacy, simple parts and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

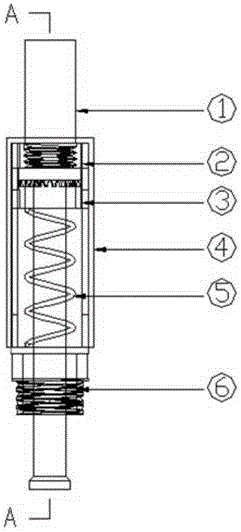

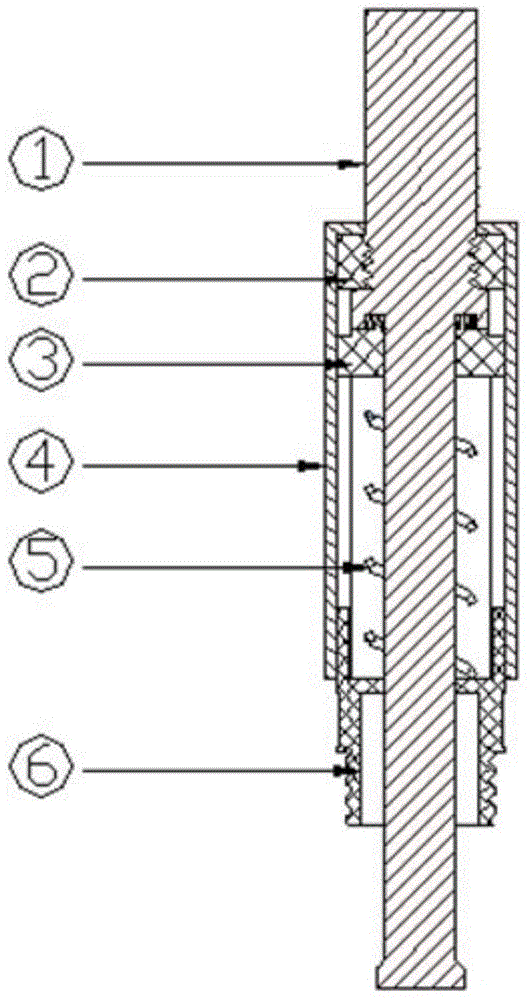

Image

Examples

Embodiment

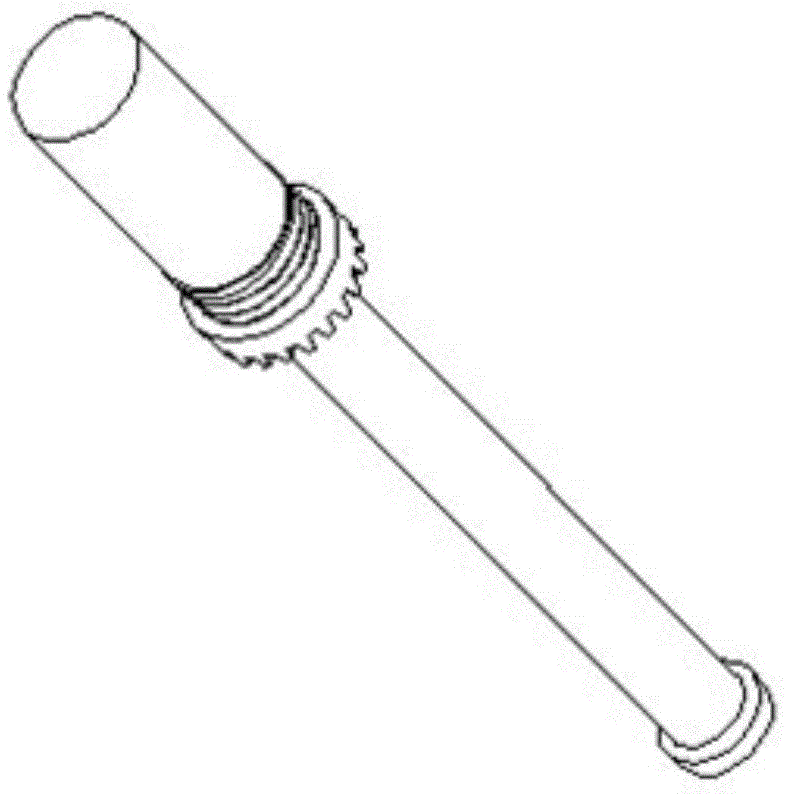

[0036] (1) Design the pitch of the threaded part on the push rod 1 to be 1mm, the thread length to be 4mm, and the circular rotation angle of each triangular tooth on the triangular movable jingle wheel 3 to be 10.44° (that is, to ensure the minimum displacement of each scale 1 μl.)

[0037] (2) When in use, first rotate the push rod 1 to the left by 104.4° (that is, the ten scales on the triangular movable jingle wheel 3), and mark it on the casing to ensure the accuracy of the exhaust. If the exhaust is not exhausted, then you can continue to rotate the exhaust for many times, and the triangular movable thorn wheel 3 can be used as an exhaust feedback device, and the rotation sends a sound reminder.

[0038] (3) After the exhaust is completed, press the push rod 1 directly downward to realize direct injection. This moment, the triangular movable jingle wheel 3 also moves downward along the groove of the inner wall of the pen core housing 1 . Due to the effect of the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com