Contactless electrical power supply device

A non-contact power supply and non-contact technology, applied in circuit devices, electrical components, electrical components, etc., can solve the problems of increased load weight, disconnection, etc., and achieve the effect of easy frequency adjustment and elimination of the increase in load weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

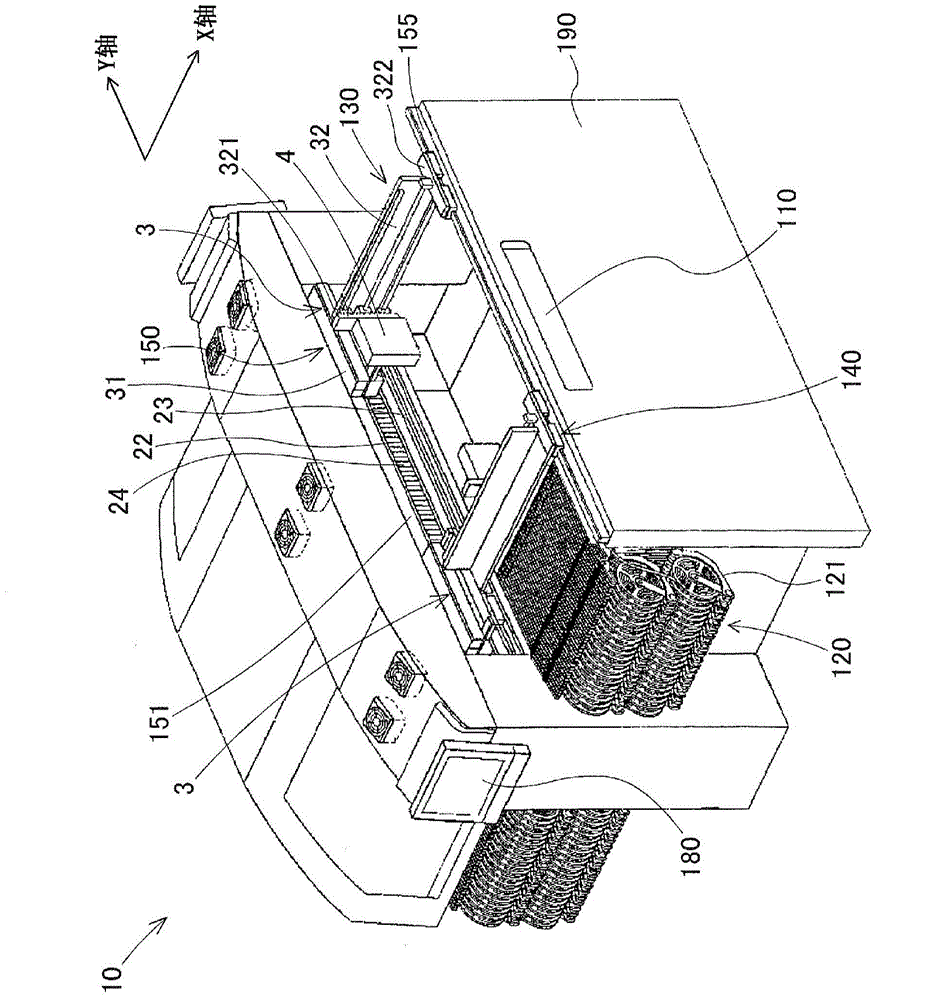

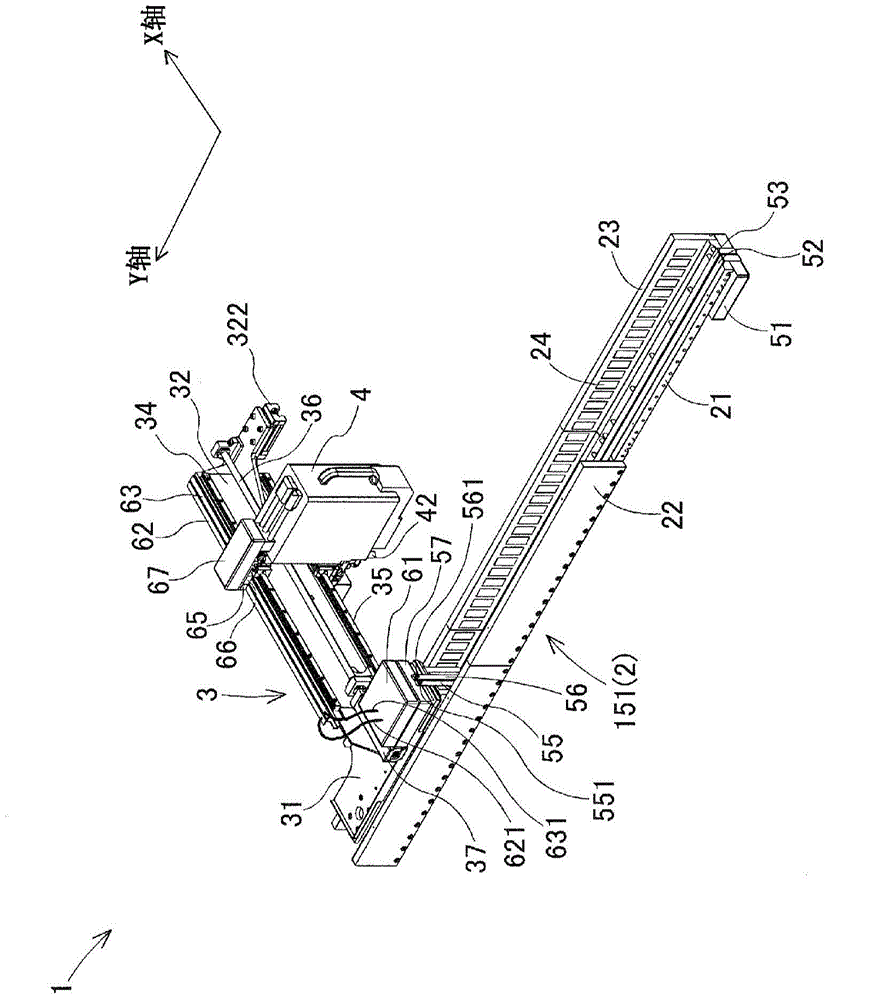

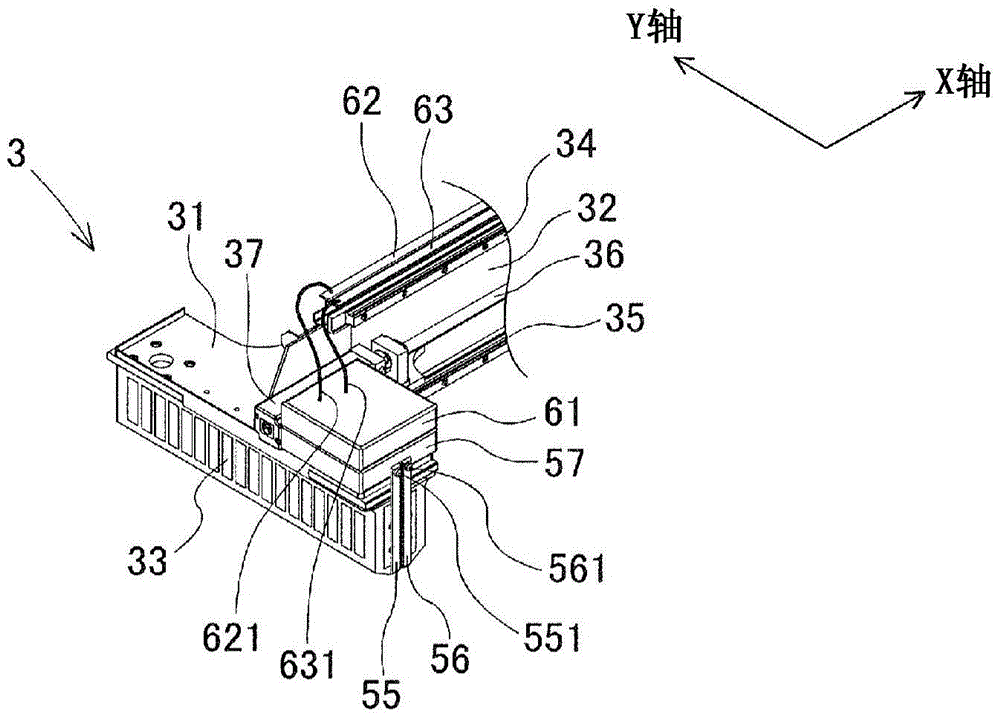

[0037] First, the component mounting machine 10 to which the present invention can be applied will be described. figure 1 It is a perspective view showing the overall configuration of a component mounting machine 10 to which the contactless power supply device 1 according to the first embodiment of the present invention can be applied. The component mounting machine 10 is a device for mounting a plurality of components on a board, and is configured by arranging two sets of component mounting units of the same configuration substantially symmetrically. Here, to figure 1 The component mounting unit in the state where the cover on the right near front side is removed will be described as an example. It should be noted that the width direction of the component mounting machine 10 from the left rear side to the right near side in the figure is the X-axis direction of loading and unloading substrates, and the component mounting machine 10 from the left near front side to the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com