Semiconductor production line multi-product workpiece combining method

A semiconductor and production line technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, comprehensive factory control, etc., which can solve the problems of lack of systematic discussion and lack of research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further introduced below.

[0056] Take the semiconductor production scheduling standard model HP24 as an example for specific implementation. The model consists of 24 machining centers, with a total of 72 equipment, and the detailed parameters of some equipment are shown in Table 1.

[0057] Table 1 Some equipment parameters in the standard model HP24

[0058]

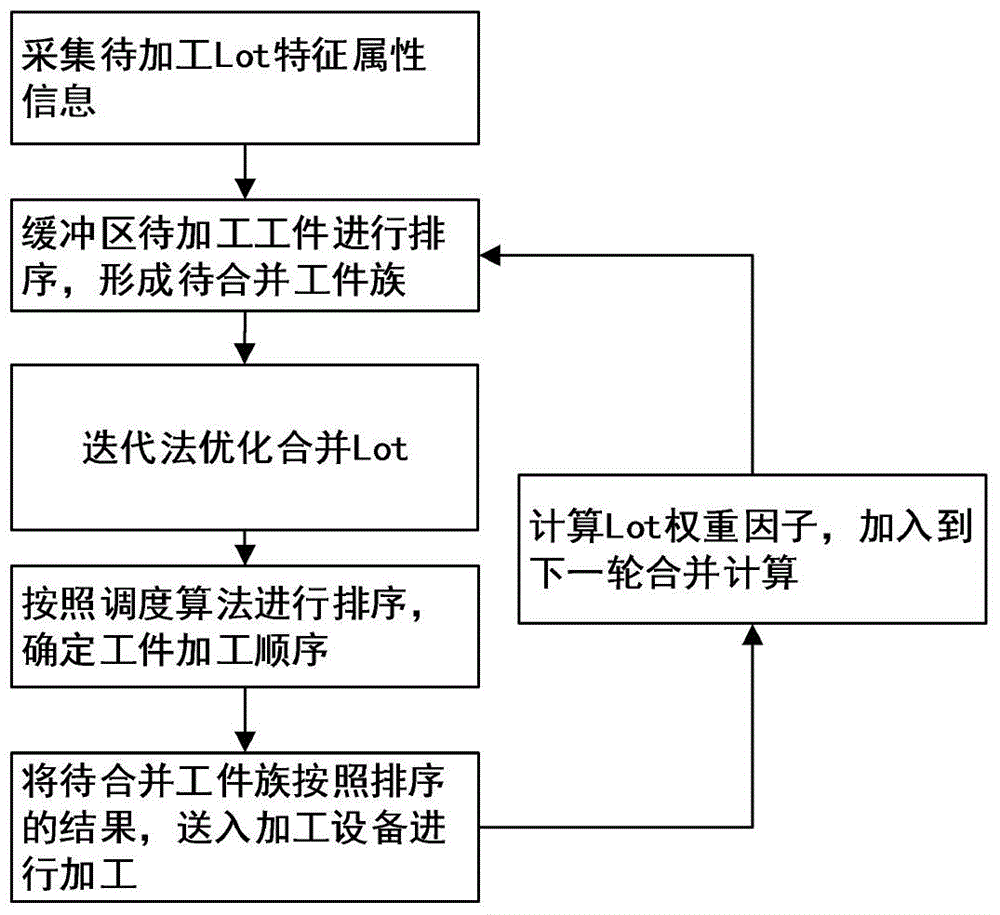

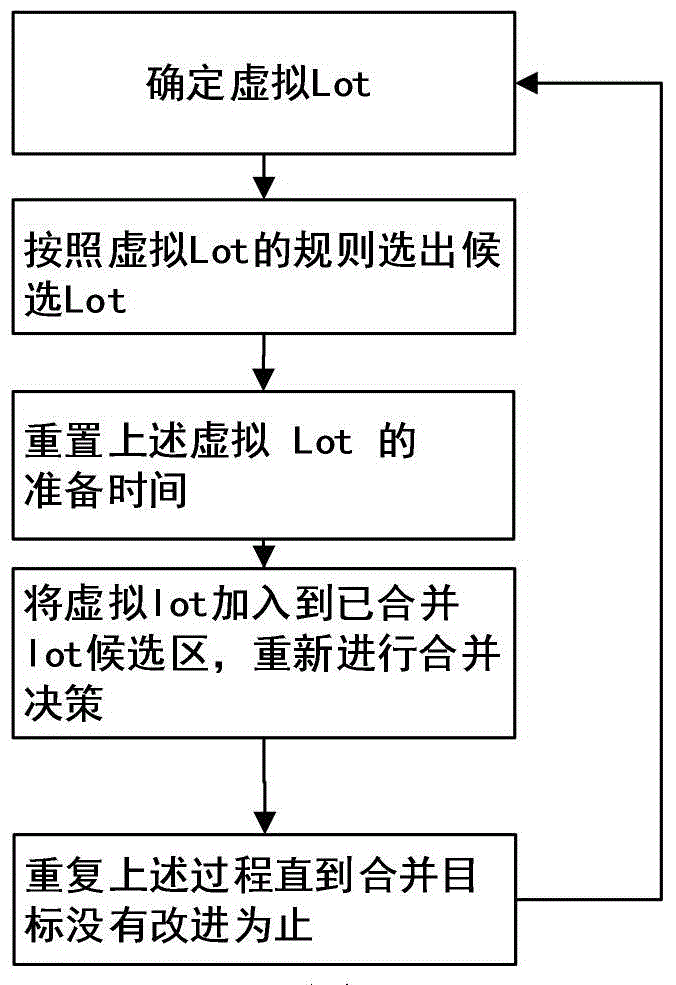

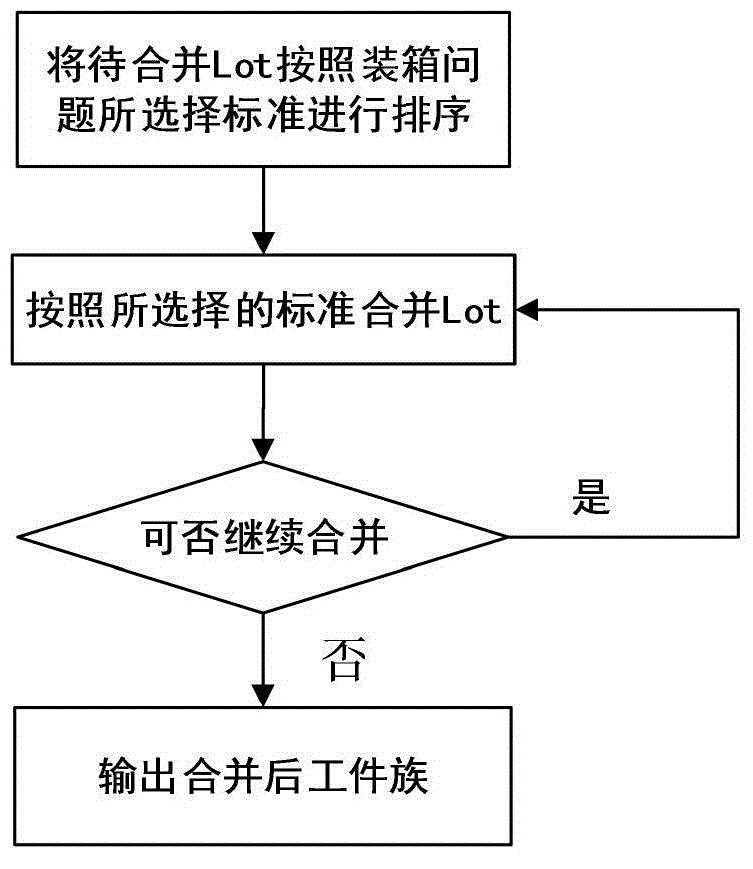

[0059] On the Plant Simulation simulation platform, the HP24 standard model is used for simulation. The dispatching rule adopts FIFO (First In First Out), the feeding strategy adopts CONWIP, the simulation time is set to 1445 hours, and the pre-simulation time is set to 365 hours. Figure 1-4 Shown is the main flowchart of the workpiece merging algorithm, including the following steps:

[0060] Step 1: Collect the Lot information to be processed in the buffer zone on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com