Tribometer

A tribology, friction contact technology, used in the field of rheometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

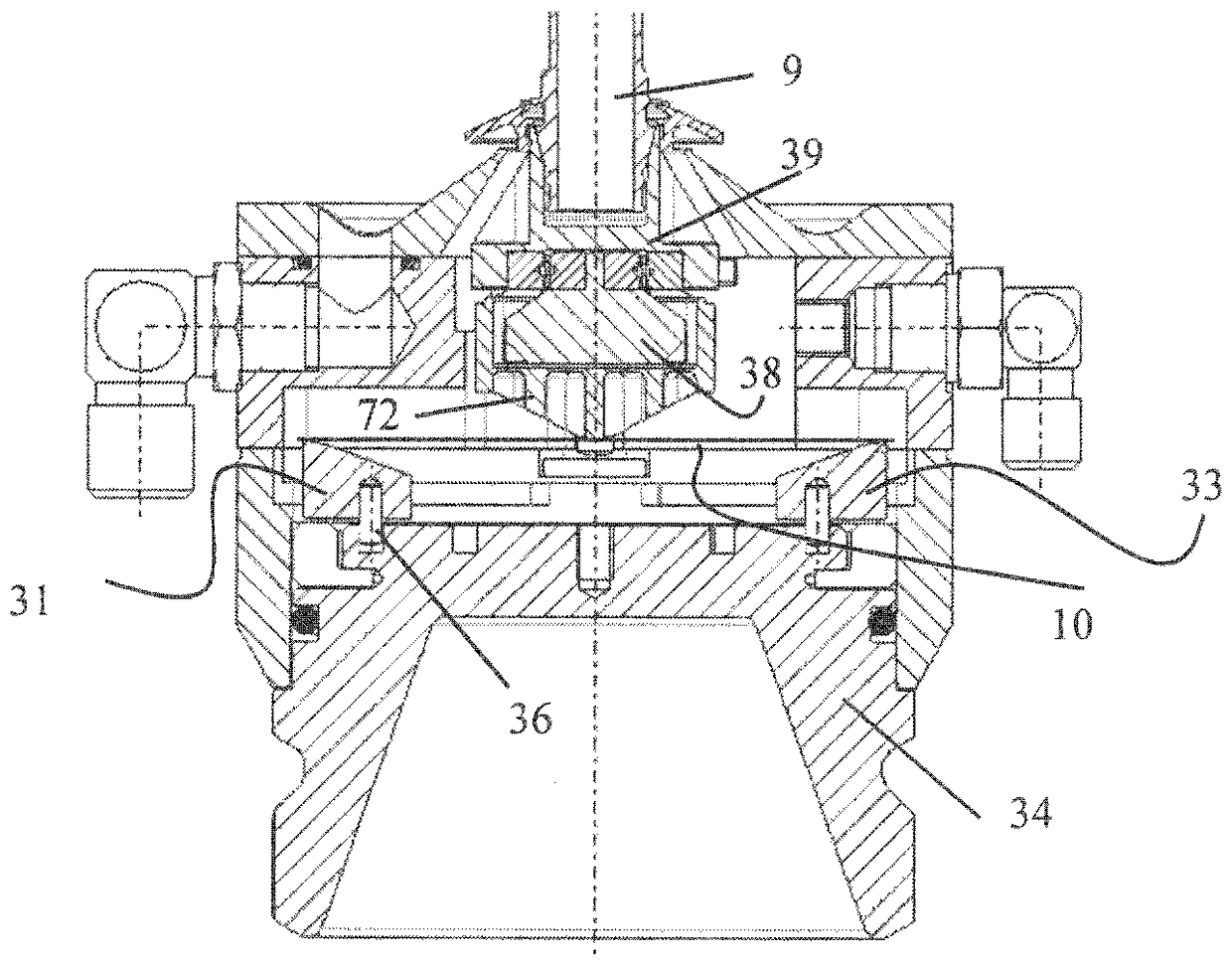

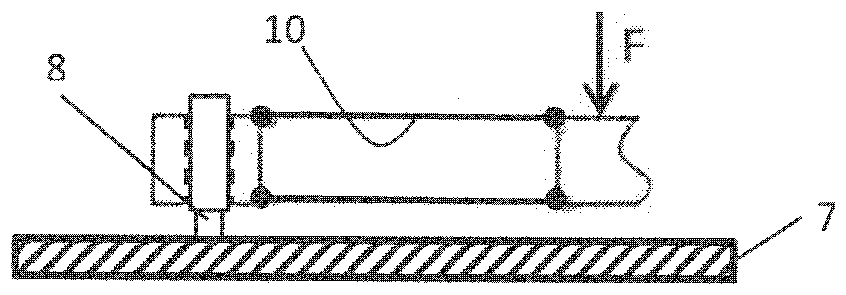

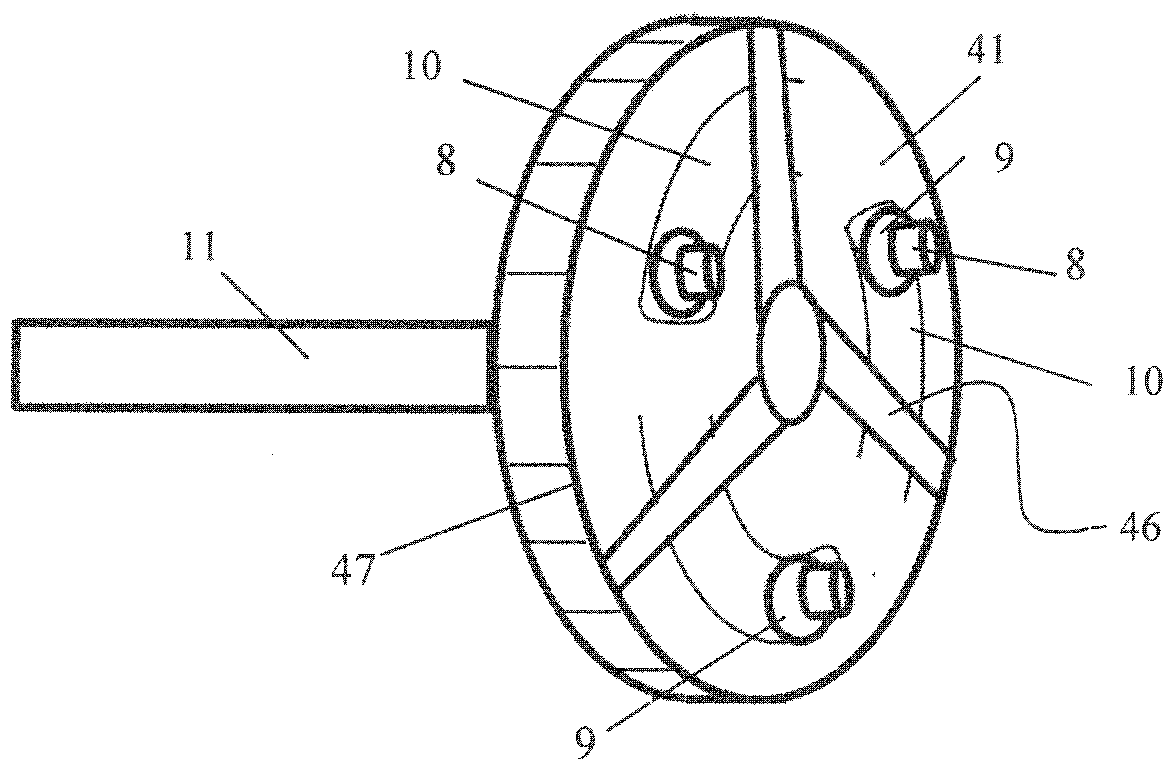

[0067] image 3 The shown rheometer 1 comprises a measuring motor 4 and a measuring shaft 6 connected to the measuring motor 4 , at the lower end of which a sample 7 in the form of a ball is mounted above it. By means of a normal force control unit, eg provided in the evaluation and control unit 40 , the sample 7 can be pressed against the underlying sample 8 with a defined force, in particular by the previous lowering of the suspension arm 5 a. Three lower samples 8 mounted symmetrically to each other in the form of blades are in frictional contact with the ball 7 . The blade 8 is supported by a holder 9 which is then supported by a spring 10 . The holder 9 and the spring 10 define a spring unit marked 3 which extends within the length of the arrow 3'. The spring constant of this spring unit 3 can advantageously (if necessary, automatically) be varied via the control and evaluation unit 40 by means of the adjustment mechanism or the adjustment unit 13 . The spring unit 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com