Wavy gasket spring elasticity detecting device and method

A spring force and detection device technology, which is applied in the direction of measuring devices, force/torque/work measuring instruments, mechanical parts testing, etc., can solve the problem of inability to replace and measure wave-shaped washer springs, fail to meet actual production needs, and the size of the tested spring Shape limitations and other issues, to achieve the effect of installation and measurement stability, practical and cheap, reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

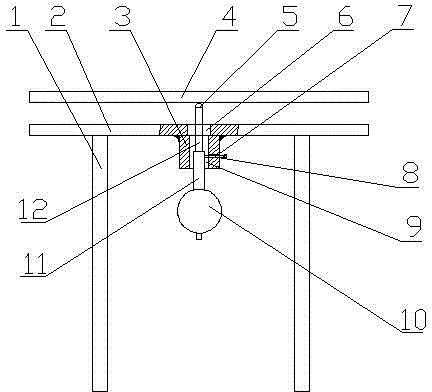

[0027] In the following, with reference to the drawings and preferred embodiments, the specific implementation, structure, features and effects of the device for detecting spring force of a wave-shaped washer spring and its detection method according to the present invention will be described in detail as follows.

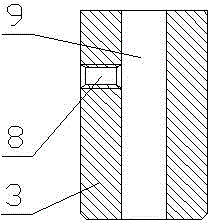

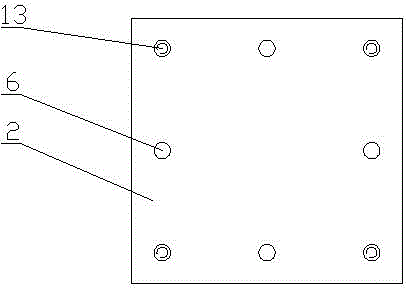

[0028] see Figure 1 to Figure 3 , the wavy washer spring elastic force detection device of the present invention comprises a fixed sleeve 3 and a base 2, wherein: the upper end of the bracket 1 is connected with the base 2, the bottom of the through hole 6 provided on the base 2 is equipped with a fixed sleeve 3, and the fixed sleeve 3 is provided with There are an inner hole 9 and an adjustment hole 8, the inner hole 9 is a through hole along the axis direction, the adjustment hole 8 is perpendicular to the axis direction and communicates with the inner hole 9 through the fixed sleeve 3, the axis line of the through hole 6 and the inner hole 9 Coincidentally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com