Automatic discharging device

An automatic discharging and driving device technology, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of increasing production costs and complex discharging devices, and achieve the effects of saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with specific embodiments.

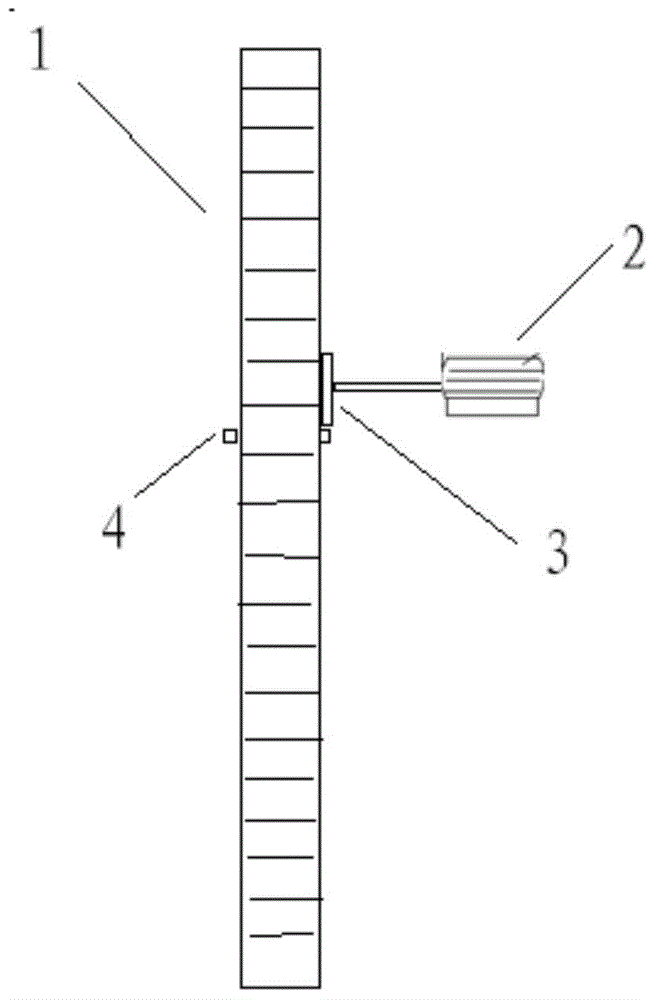

[0014] Such as figure 1 , as shown in Fig. 2, the invention includes a discharge conveyor belt 1, a driving device 2, a push plate 3, and a detection sensor 4; The push plate 3 is connected to the driving device 2 .

[0015] When the detection sensor 4 detects materials that do not meet the quality requirements, the driving device 2 drives the push plate 3 to push the unqualified materials down the discharge conveyor belt 1 .

[0016] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be considered as limiting the implementation scope of the present invention. All equivalent changes and improvements made according to the application scope of the present invention shall still belong to the scope covered by the patent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com