Sealing structure

A sealing structure and sealing ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reducing friction, poor wear resistance, poor sealing effect, etc., to improve wear resistance and use. Longevity, improved stability and reliability, effect of preventing mutual rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

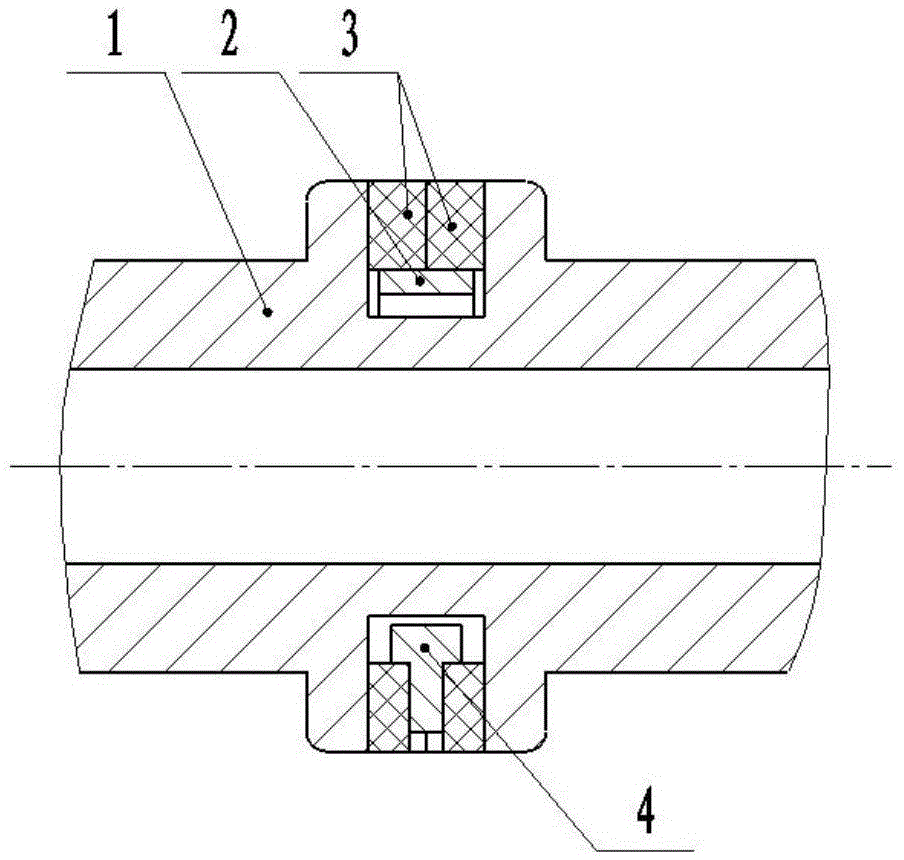

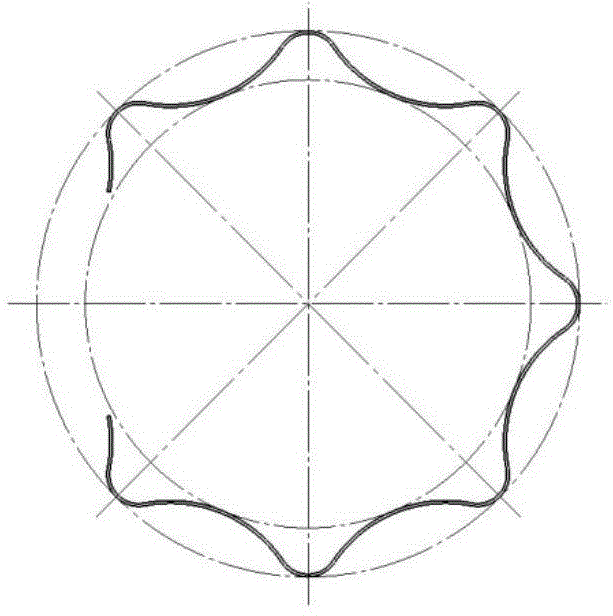

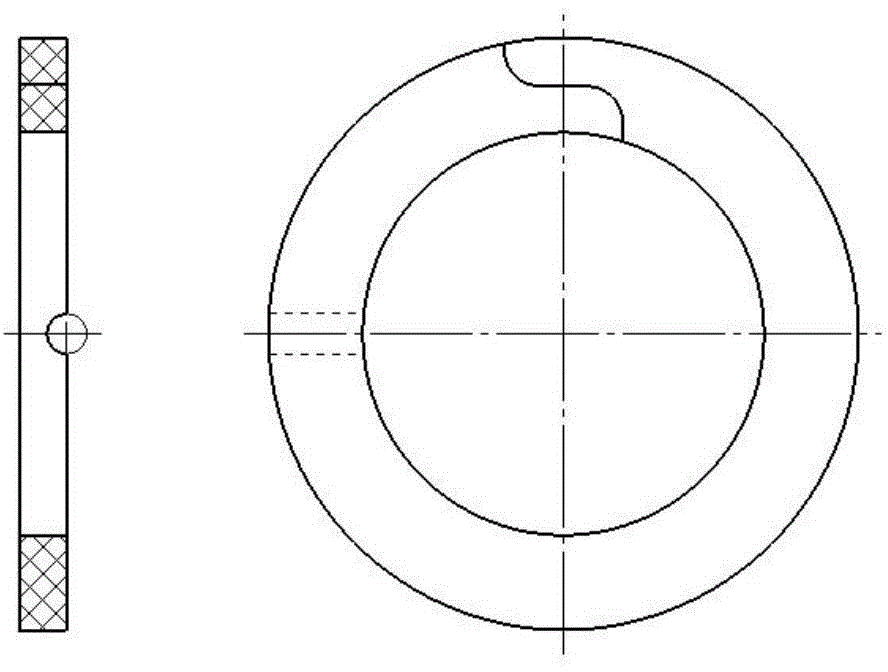

[0017] A sealing structure includes a piston rod 1, a wave spring 2, two sealing rings 3, and a pin 4. In the design of the sealing ring, except for the cutout, the rest surface roughness should be better than Ra=0.8. The quality of wave springs shall be verified by tests. During the installation process, ensure that the pin 4 is supported at the opening of the wave spring, and check whether the two notches of the sealing ring are effectively staggered by 180°. In order to further ensure the sealing effect of the sealing ring, the assembled components can be put together in an oven at a certain temperature to shrink the sealing ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com