Light and practical transmission shifting fork

A transmission and practical technology, applied in the field of mechanical parts, can solve the problems affecting the overall structure and weight of the transmission, increasing the difficulty of the operator, and the heavy and heavy structure of the shifting fork, achieving compact structure, relative weight reduction, and easy installation and positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

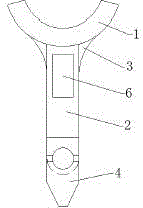

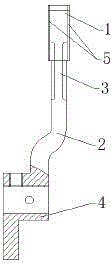

[0014] Such as figure 1 and figure 2 As shown, a portable and practical transmission shift fork includes a fork face 1, a connecting rod 2, a connecting rod reinforcement rib 3 and a shift fork sleeve 4, the fork face 1 is connected in parallel with the connecting rod 2, and the connecting rod 2 The rod reinforcing rib 3 is arranged at the joint between the fork surface 1 and the connecting rod 2. On both sides of the connecting rod 2, the shape of the connecting rod 2 is a Z-folded arc, and the connecting rod 2 is on the same side The height of the Z folding arc is 20-22mm, the front and rear sides of the connecting rod 2 are provided with grooves 6, the connecting rod 2 is connected in parallel with the shift fork sleeve 4, and the bottom surface of the connection between the two is on the same plane , effectively reducing unnecessary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com