Dustproof cover of vehicle shock absorber

A technology of automobile shock absorber and dust cover, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., which can solve the problems of easy deformation and achieve the effect of simple structure and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

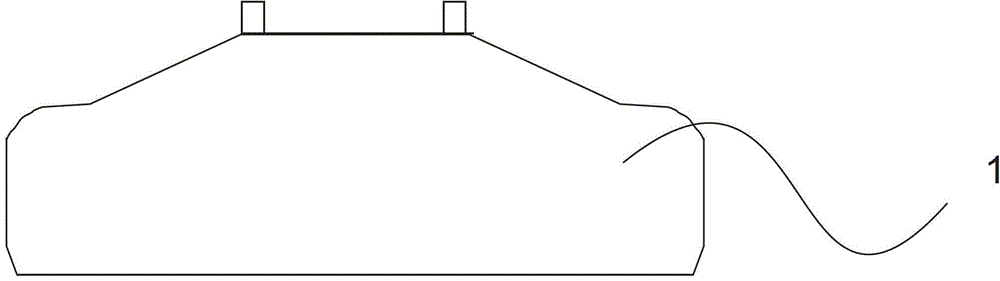

[0015] like figure 1 Shown is an automotive shock absorber dust cover.

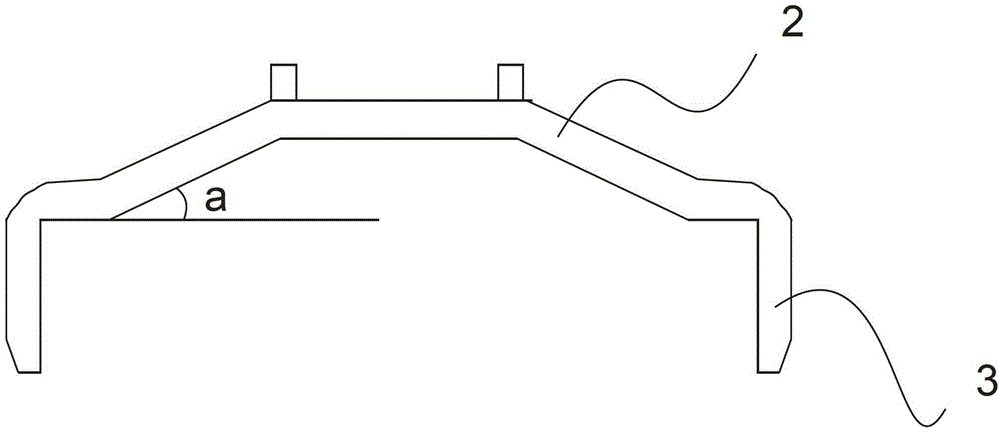

[0016] like figure 2 As shown, the dustproof cover body 1 includes an upper end surface 2, the bottom circumference of the upper end surface is provided with a visor 3, the section of the upper end surface 2 is a circular frustum structure, and the center of the upper end surface top of the upper end surface 2 is opened. A circular hole 4 is arranged for the piston rod to pass through.

[0017] After the pressure bearing test, when the angle a between the slope of the upper end surface 2 and the horizontal plane is 25°, the stress bearing effect is the best.

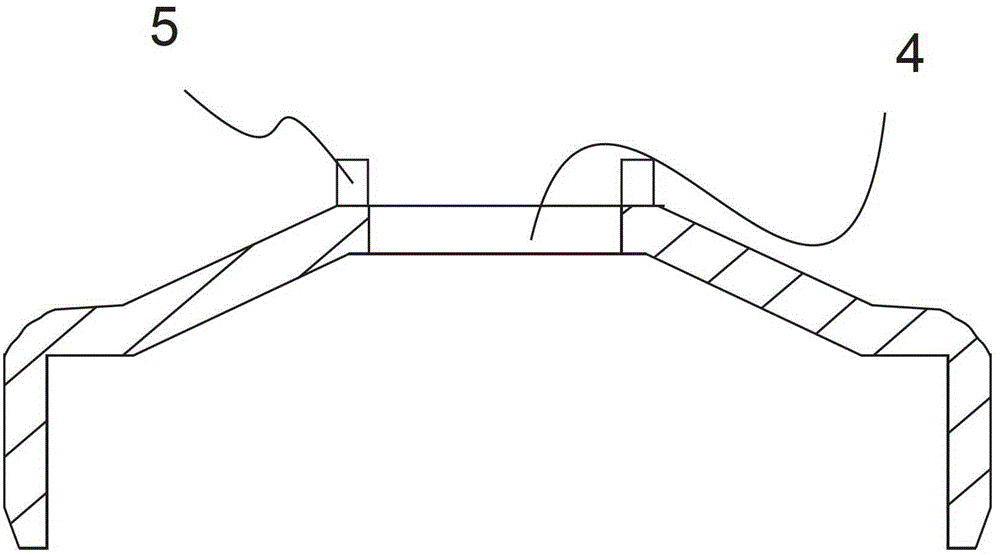

[0018] like image 3 As shown, there are two symmetrical positioning protrusions 5 extending outward from the upper diameter of the dustproof cover body 1 .

[0019] To sum up, the structure of the dustproof cover of the present invention is simple, and the upper end surface 2 is set as a slope structure, which can effectively buffer the stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com