The hydraulic system of the horizontal opening and vertical rotating protective sealing and anti-flooding door

A hydraulic system and anti-flood door technology, applied in the field of hydraulic systems, can solve the problems of high headroom in the machine room, affecting the opening and closing of the anti-flood door, and increasing maintenance costs, and achieve the effect of fast and safe closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described below in conjunction with the accompanying drawings.

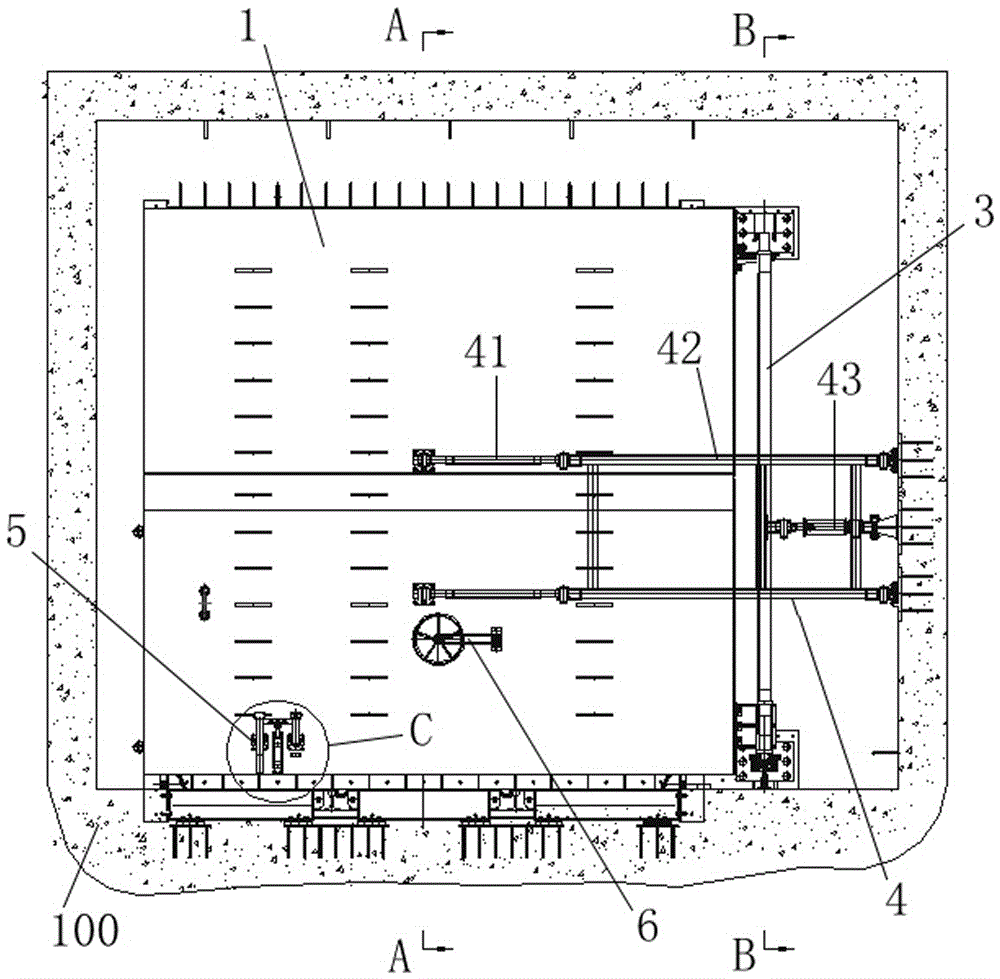

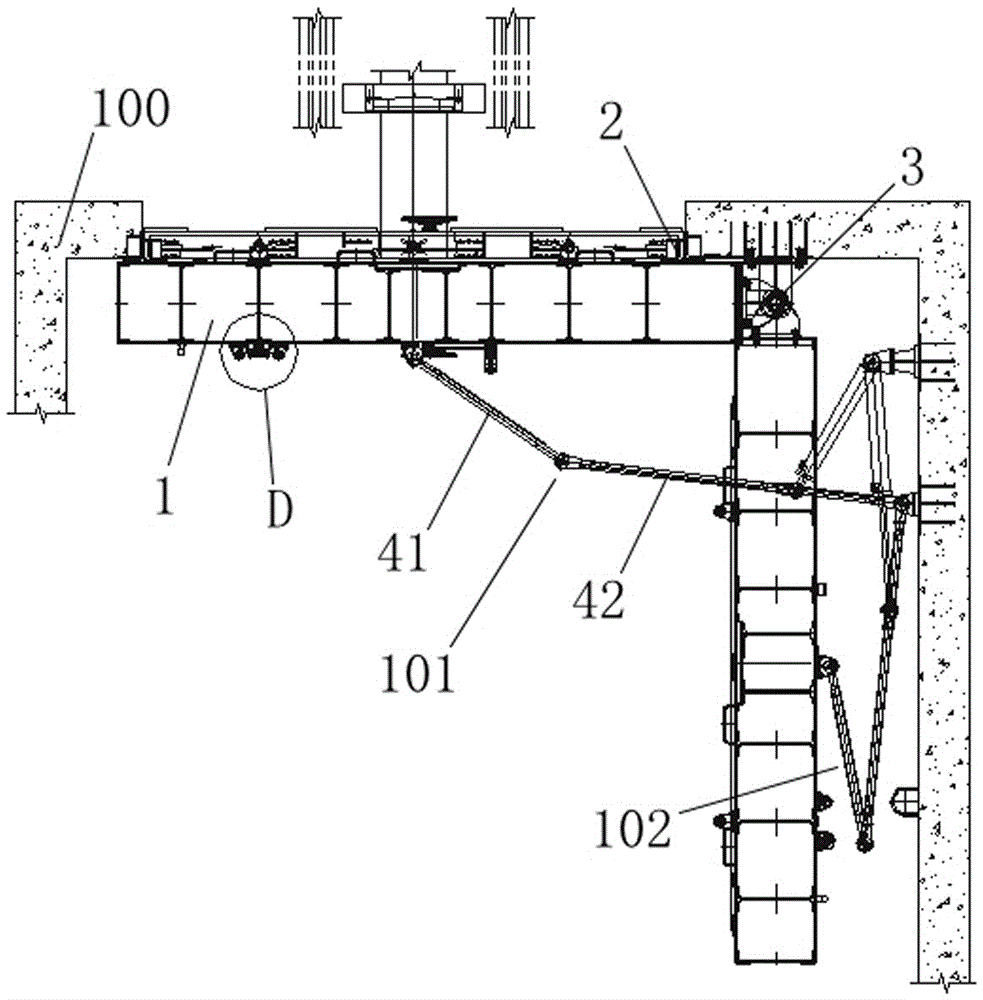

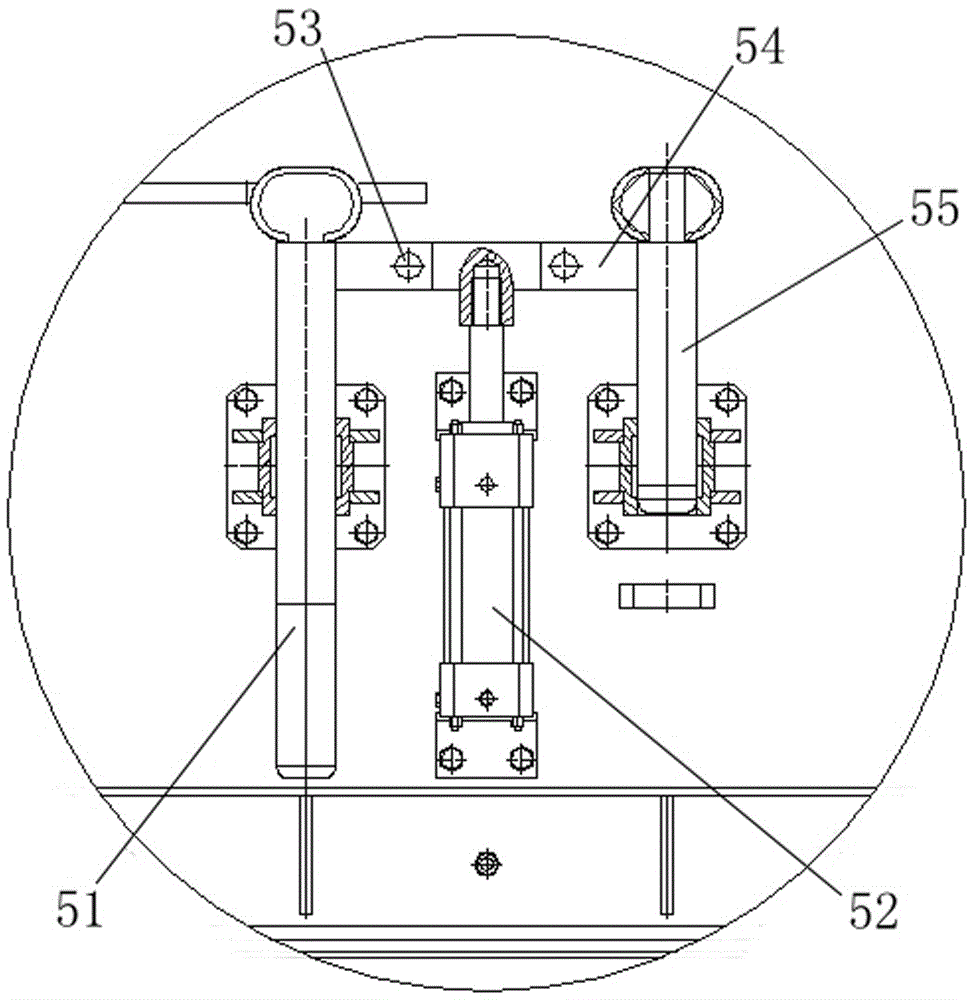

[0023] Such as figure 1 with figure 2 As shown, the side-opening and vertical-turning protective airtight and anti-flooding door is installed in the main line of the subway, has the function of airtight partition, and can realize fast and safe closing when the subway tunnel is flooded. It includes door leaf 1, steel door frame 2. The hinge 3, the opening and closing device 4, the limit device 5 and the locking device 6, the steel door frame 2 is fixed in the wall 100, the door leaf 1 is connected to the steel door frame 2 through the hinge leaf 3, and the door leaf 1 can wrap around the hinge leaf 3 Rotate and rotate; wherein, when the door leaf 1 rotates to fit with the steel door frame 2, the closing of the flat-opening and vertical-rotating protective airtight and anti-flooding door is realized, and when the door leaf 1 rotates away from the steel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com