Cartridge mechanical sealing structure

A mechanical seal, cartridge technology, applied in mechanical equipment, variable displacement pump components, machines/engines, etc., can solve the problems of guaranteed seal installation quality, inconvenient installation, etc., to achieve reliable performance, convenient installation and maintenance, Use the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

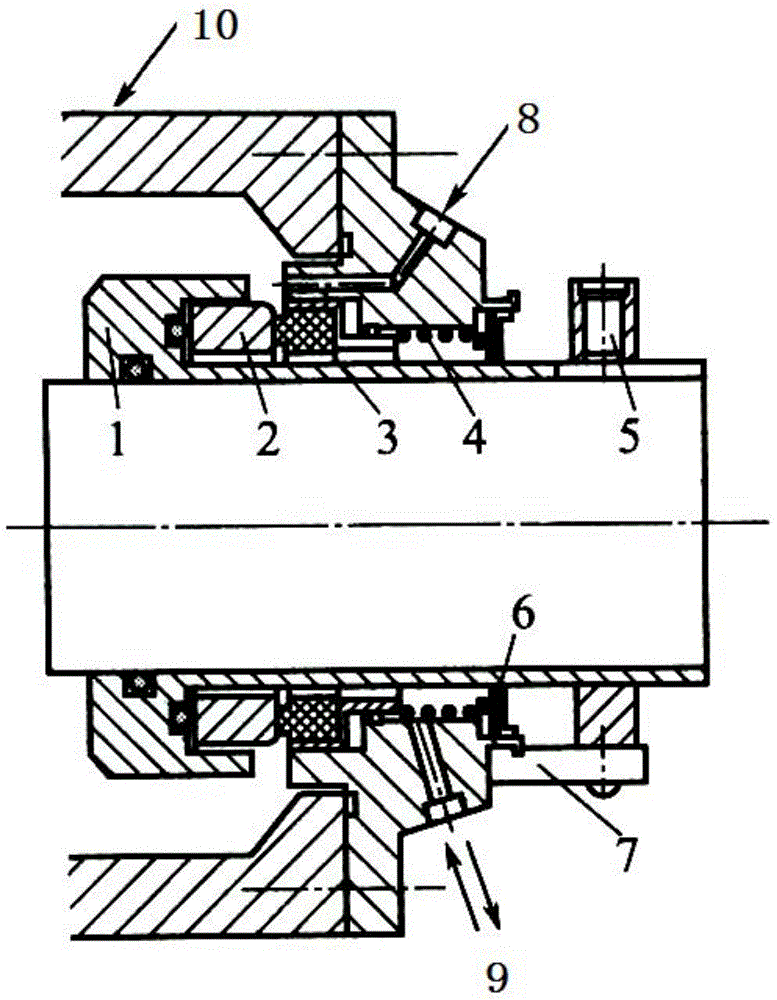

[0010] Such as figure 1 The shown cartridge mechanical seal structure includes a shaft sleeve 1, a moving ring 2, a static ring 3, a spring 4, a snap ring 5, a lip seal 6 and a limit block 7, and the shaft sleeve 1 passes through The fastening screw is connected to the shaft, the bushing 1 is connected with the moving ring 2 by interference fit, the static ring 3 is connected to the static ring seat, the static ring seat is connected to the gland, and the inside of the gland is A spring clamping groove is provided, the spring 4 is placed in the spring groove, the static ring seat is connected with the spring 4 and positioned by the snap ring 5, and the flushing liquid inlet 8 and the cooling A liquid inlet 9, a lip seal 6 is arranged between the spring 4 and the gland, and a limit block 7 is arranged at the end of the gland. The lip seal 6 is a fluorine rubber sealing ring.

[0011] When in use, you only need to clean the whole device, clean the sealing chamber and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com