Upward layered wall type bag filling mining method

A filling mining method and filling body technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of high cost of rock drilling and blasting, high cost of mining, discontinuous operation, etc., and achieve the protection of groundwater resources and ecological environment. The effect of high resource recovery rate and continuous mining operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

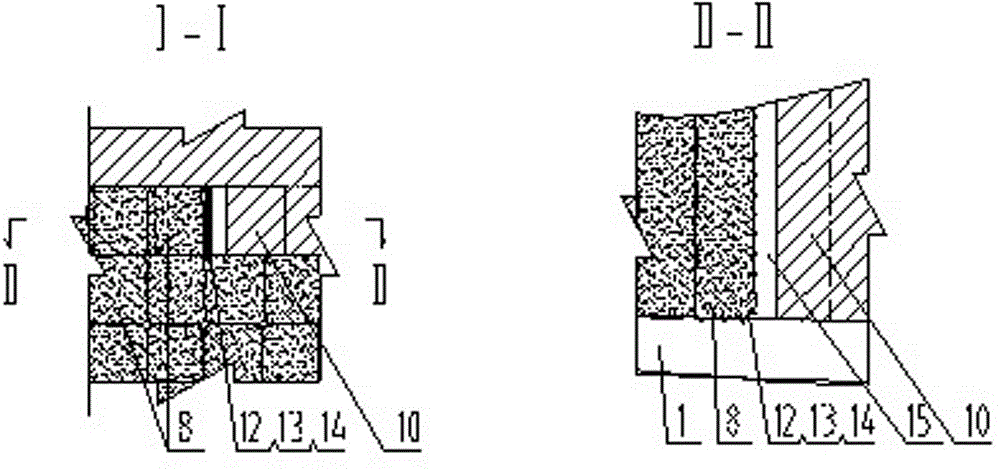

[0025] In a copper mine, the stability of the ore rock is poor, the thickness of the ore body is about 30m, the strike length is about 1000m, and the dip angle is 70°. The upward layered wall bag-fill mining method is used for mining. The stope is arranged vertically to the ore body. The stope is 30m wide and the length is the thickness of the ore body. Such as figure 2 shown. Mining is carried out one by one from one side to the other in the layering of the stope. After the mining of each approach is completed, the lead screw column is supported at a certain distance from the approach to be mined (the density of the pillar is 1m / root), so that the lead screw With horizontal side pressure, the mined-out area is divided into a reserved space and an isolated space, and then the steel wire mesh is drawn in the full height and full length of the screw column, and the filling bag is laid between the screw column and the filling body, that is, the isolation space, to carry out Fi...

Embodiment 2

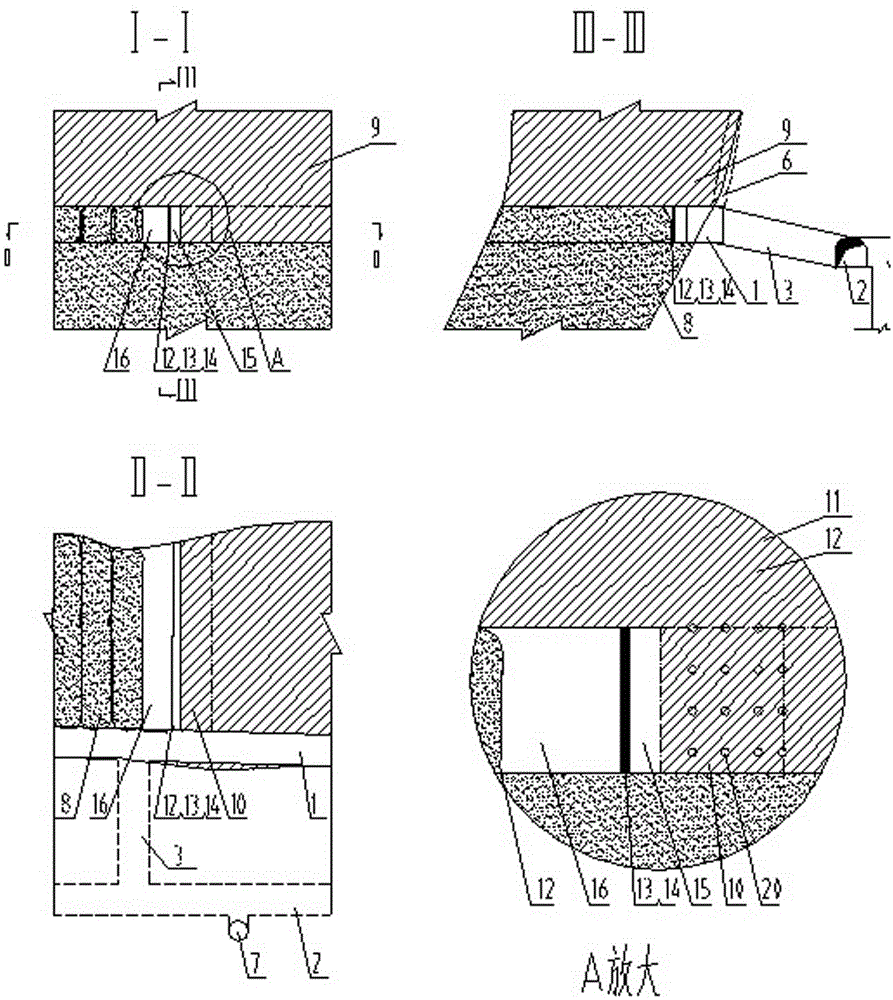

[0033] In a copper mine, the stability of the ore rock is poor, the thickness of the ore body is about 30m, the strike length is about 1000m, and the dip angle is 70°. The upward layered wall bag-fill mining method is used for mining. The stope is arranged vertically to the ore body. The stope is 30m wide and the length is the thickness of the ore body. Such as image 3 shown. Divide the mining approach in the stope stratification, the width of the approach is 3m, and the length is the thickness of the ore body. The approach adopts interval mining. The reserved empty area on the side is filled with bags in the middle, and the second phase of the road is mined after the filling body is solidified.

Embodiment 3

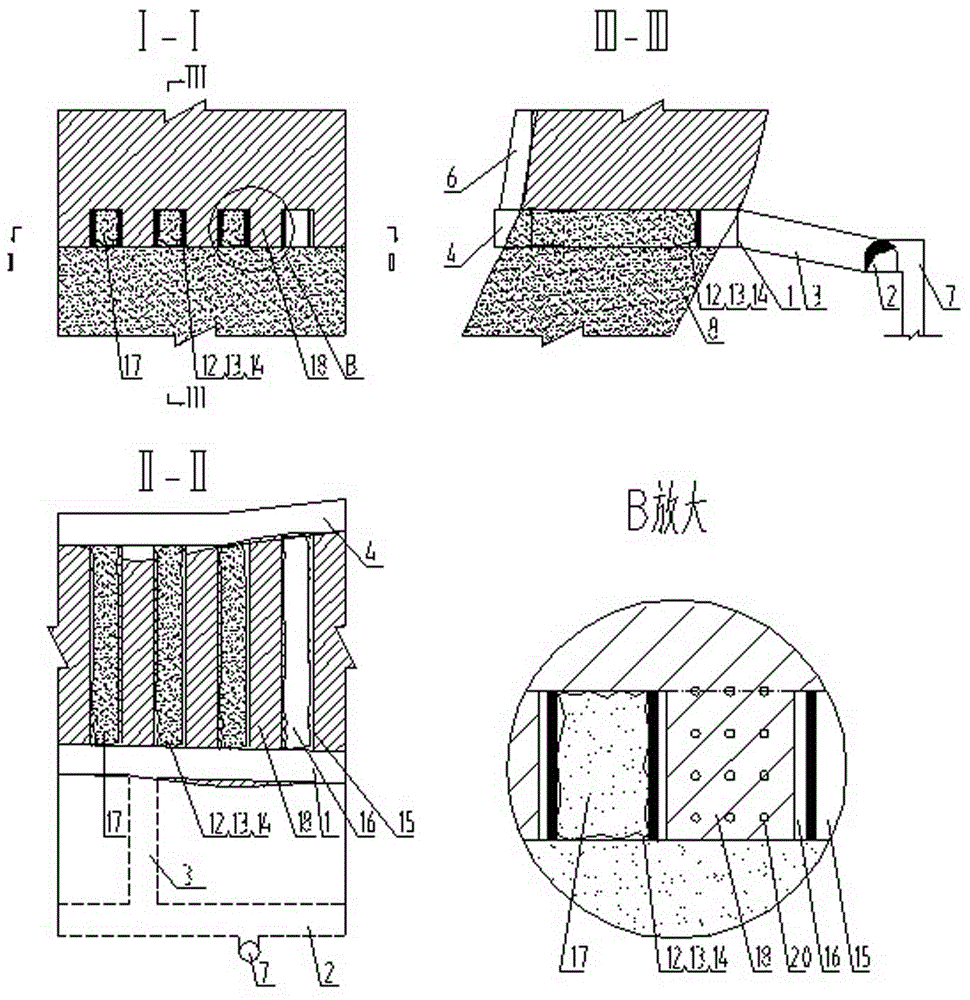

[0035] A kind of bauxite, the thickness of the ore body is about 3m, the inclination angle is 8°, and the ore rock is moderately stable. According to the calculation of rock mechanics, the allowable exposed span of the stope is 4m.

[0036] When the ore body adopts the upward layered wall bag filling mining method, the panel is arranged vertically to the ore body, and the stope is divided in the panel, and the stope is arranged vertically to the ore body. The stope is 60m long in direction and 50m incline. Such as Figure 4 shown.

[0037] The mining and cutting works include: subsection level roadway 2, filling and returning wind level way along the vein 4, returning wind level way along the vein, returning wind up the mountain 6, cutting lane, etc.

[0038] Mining and filling: Excavate a cutting roadway at the end of the stope along the ore body inclination, with a specification of 4m×3m (width×height), support pillars at a distance of 1m from the working face, and divide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com