Special work robot for vertical shaft construction

A kind of operating robot and special technology, applied in shaft equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as poor shoveling accuracy, reduced operating efficiency and quality, and unsatisfactory loading effect of rock grabbing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

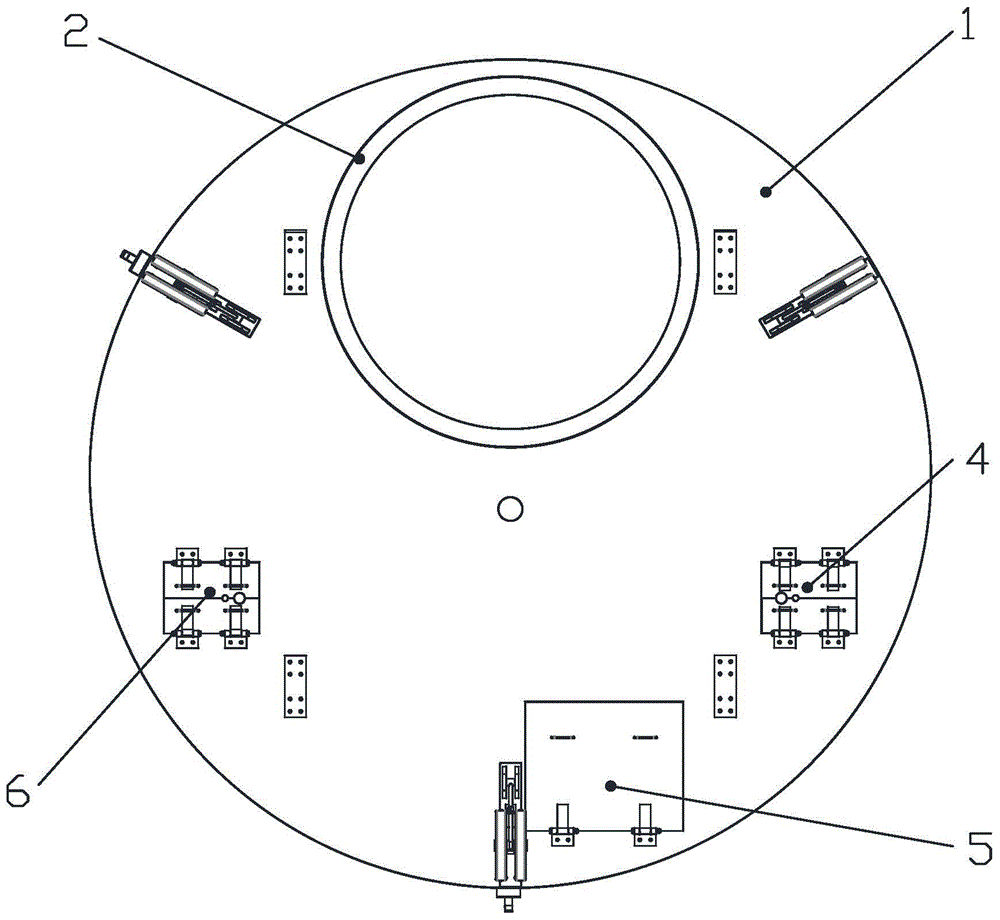

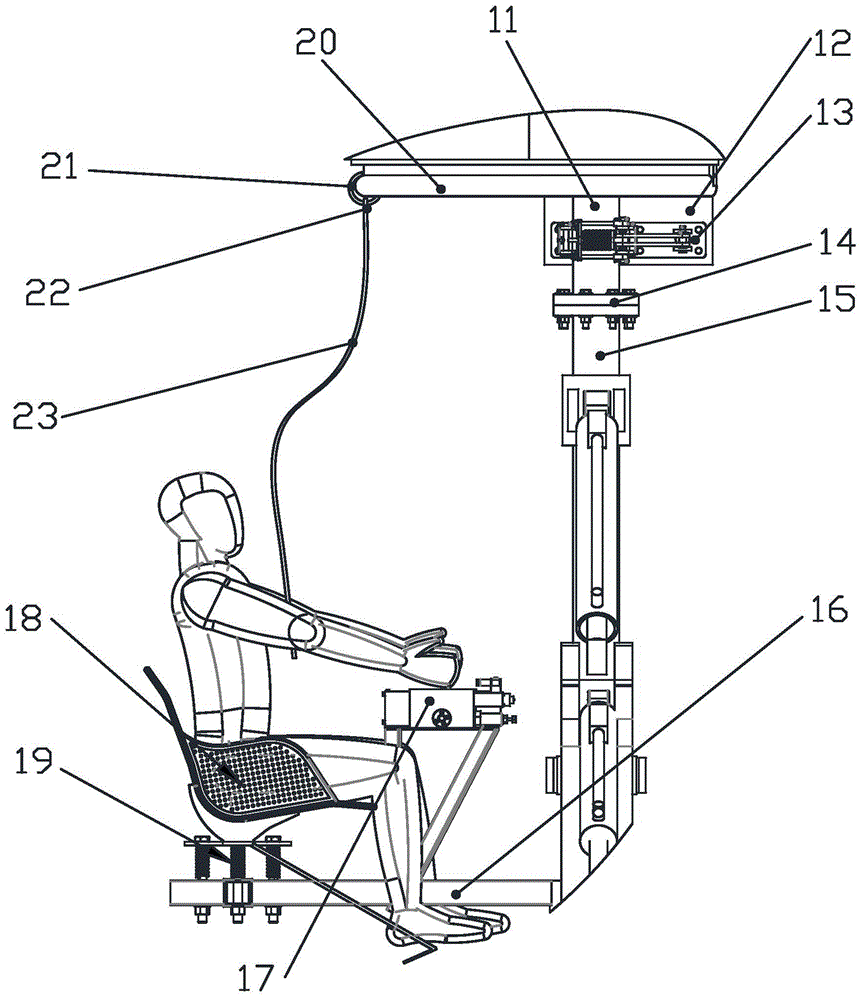

[0019] Such as Figure 1 to Figure 3 As shown, the vertical shaft construction special operation robot includes upper and lower two-layer suspension pan assemblies 1, which are fixedly connected by columns 8 between the two-layer suspension pan assembly 1, and an excavation assembly and a console are arranged below the two-layer suspension pan assembly 1. The suspension pan assembly 1 of the upper strata is a protection suspension pan, the suspension pan of the lower floor is a work suspension pan, and the control console is positioned at the bottom of the lower floor suspension pan, thus making the viewing field of vision clear and convenient for excavation to be carried out on-site control.

[0020] Bell mouth assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com