A low-position pressure roller

A sizing roller and low-level technology, applied in the field of sizing rollers, can solve the problems affecting sizing enhancement, straightening and wear resistance, increasing edge yarn breakage, increasing sizing elongation, etc., so as to improve sizing quality, Increase the coefficient of friction and reduce the effect of relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

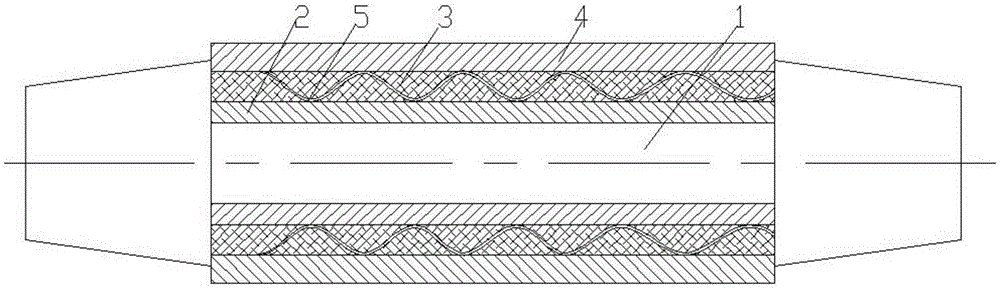

[0011] A low-position pressure roller according to the present invention includes a metal roller core 1 and a rubber layer, and the rubber layer is mainly composed of a bottom rubber layer 2, a slow rubber layer 3 and a surface layer 4. The slow rubber layer 3 There is a gap layer 5 inside; the gap layer 5 is in the shape of a wavy hole, extending inward from one end of the slow rubber layer 3, and is a closed blind hole structure; the gap layer is filled with hot air. By filling the hot air in the slow glue layer 3, the friction coefficient of the surface layer 4 is increased, the relative movement is reduced, the yarn damage caused by slippage is overcome, the sizing is uniform, the penetration and coating are good, and the penetration and coating of the yarn are considered and strengthened. Significant improvements have been made in the reduction of horizontal stripe spots and edge s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com