A kind of thick steel plate for welding with low carbon equivalent and large input energy and its manufacturing method

A large input energy welding and manufacturing method technology, applied in the field of thick steel plate manufacturing for welding, can solve the problems of reducing the impact toughness of base metal and welding heat-affected zone, difficult to improve the toughness of welding heat-affected zone, difficult to disperse distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with embodiment.

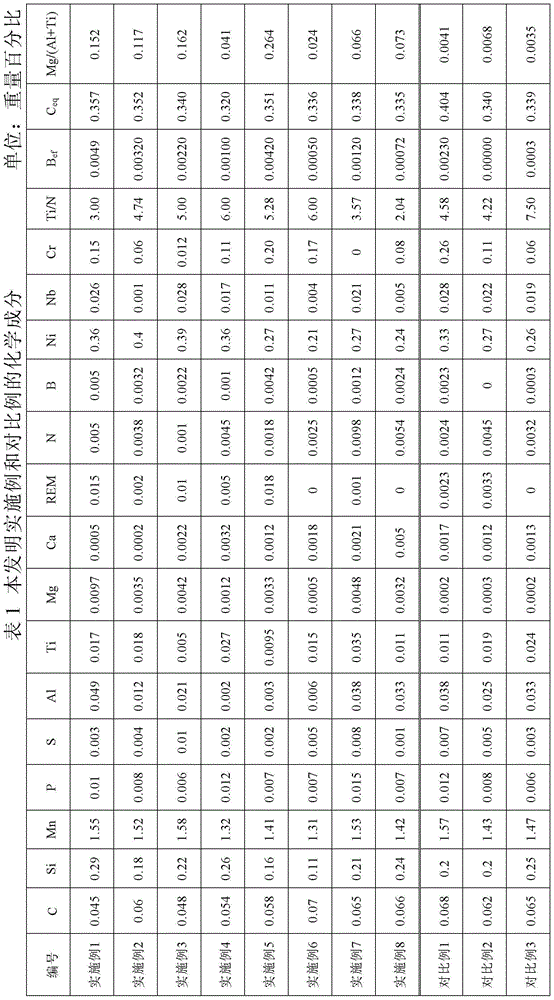

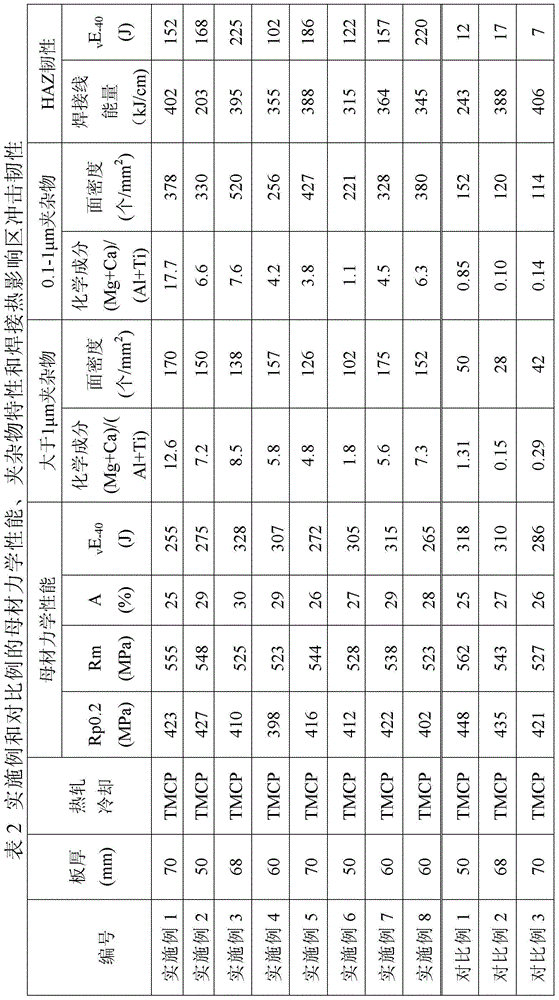

[0064] Table 1 is the chemical composition, Ti / N, B of the embodiment of the present invention and comparative example ef 、C eq and Mg / (Al+Ti) ratio. Table 2 shows the mechanical properties, inclusion properties and impact toughness of the welded heat-affected zone of the examples and comparative examples of the present invention.

[0065] The manufacturing method of the thick steel plate with low carbon equivalent and large input energy welding of the present invention is as follows: smelting, refining and continuous casting to obtain the chemical composition of the billet as shown in Table 1; then the billet is heated to 1050°C-1250°C, The rolling temperature is 1000-1150°C, and the cumulative reduction rate is 50%; the finish rolling temperature is 700-850°C, and the cumulative reduction rate is 53-67%; The surface temperature of the steel plate is cooled from above 750°C to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com