Low-nickel aging-strengthened iron-nickel-based corrosion-resistant alloy and preparation method thereof

An age-strengthening, corrosion-resistant alloy technology, applied in the field of metal materials, can solve the problem of not obtaining significant breakthroughs, and achieve the effect of excellent overall process performance, excellent corrosion resistance, and reduced hot cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 500kg of alloy was melted by vacuum induction, casted into a round bar of Φ170mm, and then electroslag remelted into a steel ingot of Φ280mm. The ingot number is N73. The chemical composition of the alloy is shown in Table 1. The steel ingot is placed in a high-temperature well-type furnace for homogenization heat treatment, and then forged into a Φ100mm round bar. The bar is subjected to aging heat treatment, wire cutting sampling, and processed samples to test its tensile properties, hardness and impact energy. The properties are shown in the table 2. The material is used for downhole tools in oil and gas fields.

Embodiment 2

[0044] 1000kg of alloy was melted by vacuum induction, cast into a round rod of Φ220mm, and remelted into a steel ingot of Φ380mm by electroslag remelting. The ingot number is N74. The chemical composition of the alloy is shown in Table 1. The steel ingot is placed in a high-temperature well-type furnace for homogenization heat treatment, and then forged into a Φ200mm round bar by upsetting and drawing. The properties are shown in Table 2. This material is used for downhole tools in oil and gas fields.

Embodiment 3

[0046] 3000kg of alloy was melted by vacuum induction, cast into a round bar of Φ250mm, and remelted into a steel ingot of Φ400mm by electroslag remelting. The ingot number is N75. The chemical composition of the alloy is shown in Table 1. The steel ingot is placed in a high-temperature well-type furnace for homogenization heat treatment, and the billet is made into a Φ230mm bar through a quick forging machine for upsetting and drawing, and a radial forging machine is forged, and the bar is then hot-extruded into a thick-walled tube , the pipe is subjected to aging heat treatment, wire cutting sampling, and processing samples to test its tensile properties, hardness and impact energy. The properties are shown in Table 2. This material is used for downhole pipelines in sour oil and gas fields.

[0047] 2. Alloy properties

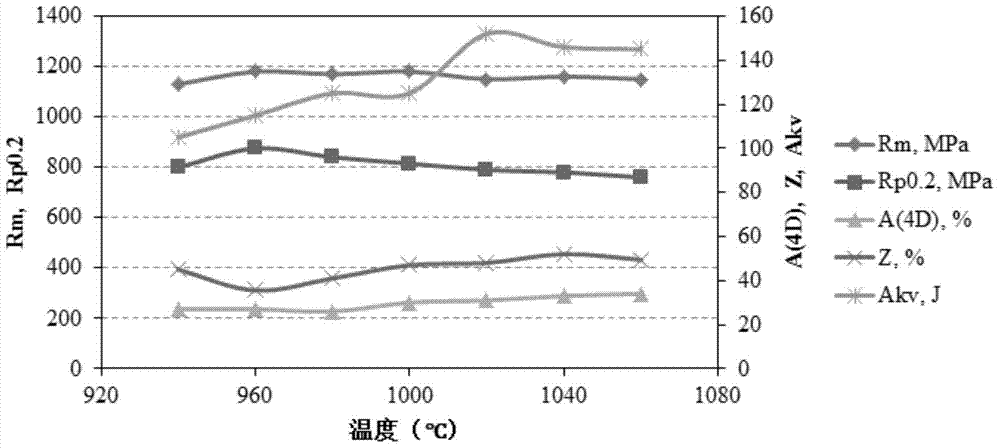

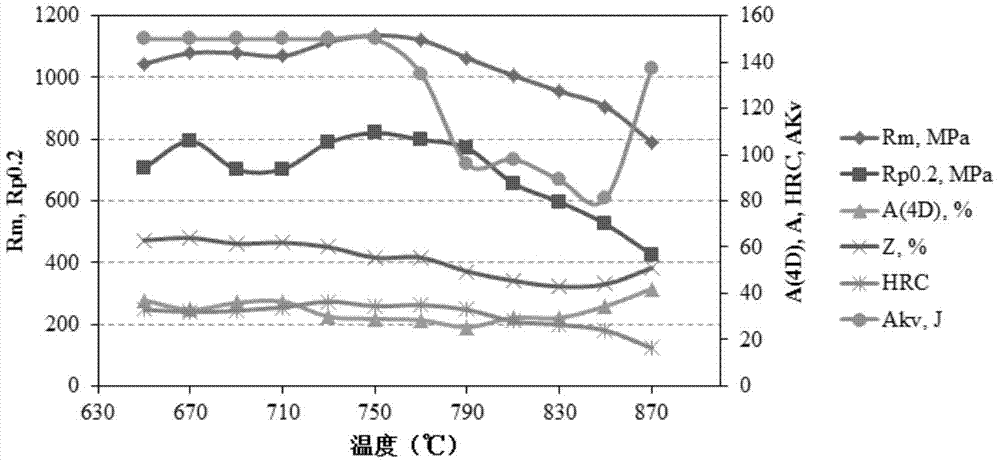

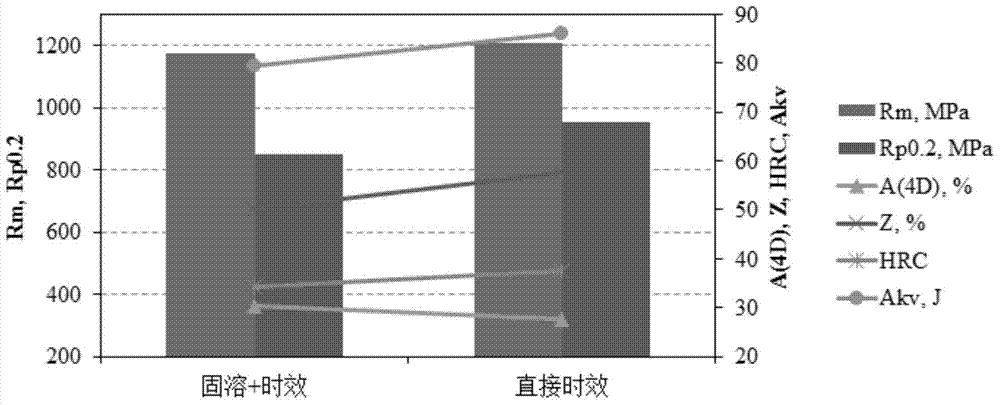

[0048] 1. Effect of heat treatment on alloy mechanical properties and alloy structure

[0049] The mechanical properties at room temperature of the alloy d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com