Method of preparing biodegradable lubricating oil

A lubricating oil and biological technology, applied in the field of lubricating oil, can solve the problem of poor wear resistance of degradable lubricating oil, and achieve the effect of good wear resistance and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

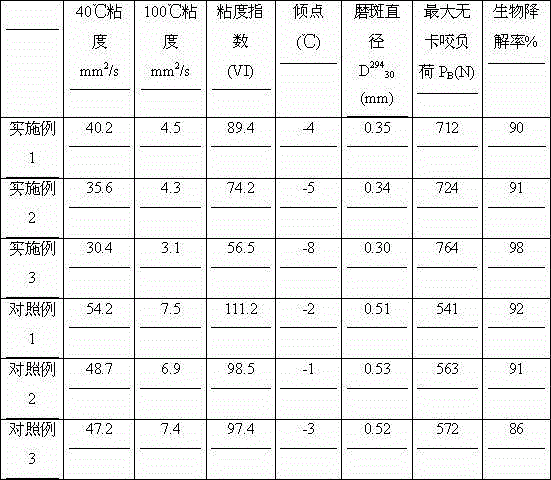

Examples

Embodiment 1

[0029] Step 1, mix 30Kg of polyol, 40Kg of vegetable oil, 3Kg of catalyst, and 80Kg of organic solvent evenly, then heat up to 70°C, and react for 2 hours to obtain polyol ester;

[0030] Step 2: Distill the obtained polyol ester under reduced pressure, steam the organic solvent, then add 30Kg of formic acid, after the temperature rises to 60°C, add 20Kg of hydrogen peroxide dropwise, after the dropwise addition, keep the temperature for 2 hours, and let it stand for stratification. Remove the water layer, distill the oil layer, collect the fraction at 190-210°C, and obtain the modified polyol ester;

[0031] Step 3: Mix the modified polyol ester with 10Kg of base oil, 2Kg of triacetin, 1Kg of xanthan gum, 1Kg of antirust agent, 1Kg of extreme pressure and antiwear agent, and 1Kg of surfactant.

[0032] Described polyhydric alcohol is methylolpropane, and described solid superacid catalyst is SO 4 2- / ZrO 2 , the organic solvent is ethanol, the vegetable oil is castor oil, ...

Embodiment 2

[0035] Step 1, mix 40Kg of polyol, 60Kg of vegetable oil, 5Kg of catalyst, and 120Kg of organic solvent evenly, then heat up to 90°C, and react for 4 hours to obtain polyol ester;

[0036] Step 2: Distill the obtained polyol ester under reduced pressure, steam off the organic solvent, then add 40Kg of formic acid, after the temperature rises to 90°C, add 40Kg of hydrogen peroxide dropwise, after the dropwise addition, keep the temperature for 4 hours, and let it stand for stratification. Remove the water layer, distill the oil layer, collect the fraction at 190-210°C, and obtain the modified polyol ester;

[0037] Step 3: Mix the modified polyol ester with 20Kg of base oil, 4Kg of glycerol triacetate, 3Kg of xanthan gum, 1Kg of antirust agent, 1Kg of extreme pressure and antiwear agent, and 1Kg of surfactant.

[0038] Described polyhydric alcohol is methylolpropane, and described solid superacid catalyst is SO 4 2- / ZrO 2 , the organic solvent is ethanol, the vegetable oil ...

Embodiment 3

[0041] Step 1, mix 35Kg of polyol, 50Kg of vegetable oil, 4Kg of catalyst, and 100Kg of organic solvent evenly, then heat up to 80°C, and react for 3 hours to obtain polyol ester;

[0042] Step 2: Distill the obtained polyol ester under reduced pressure, steam off the organic solvent, then add 35Kg of formic acid, after the temperature rises to 70°C, add 30Kg of hydrogen peroxide dropwise, after the dropwise addition, keep the temperature for 3 hours, and let it stand for stratification. Remove the water layer, distill the oil layer, collect the fraction at 190-210°C, and obtain the modified polyol ester;

[0043] Step 3: Mix the modified polyol ester with 10-20Kg of base oil, 2-4Kg of glycerol triacetate, 1-3Kg of xanthan gum, 1Kg of rust inhibitor, 1Kg of extreme pressure and anti-wear agent, and 1Kg of surfactant After that, you can.

[0044] Described polyhydric alcohol is methylolpropane, and described solid superacid catalyst is SO 4 2- / ZrO 2 , the organic solvent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com