Self-repairing waterborne woodware finishing coat

A self-healing, water-based technology, applied in the field of coatings, can solve problems such as reduced service life, affecting the appearance of wood, scratches and cracks, etc., to achieve the effects of prolonging service life, avoiding manual repairs, and reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

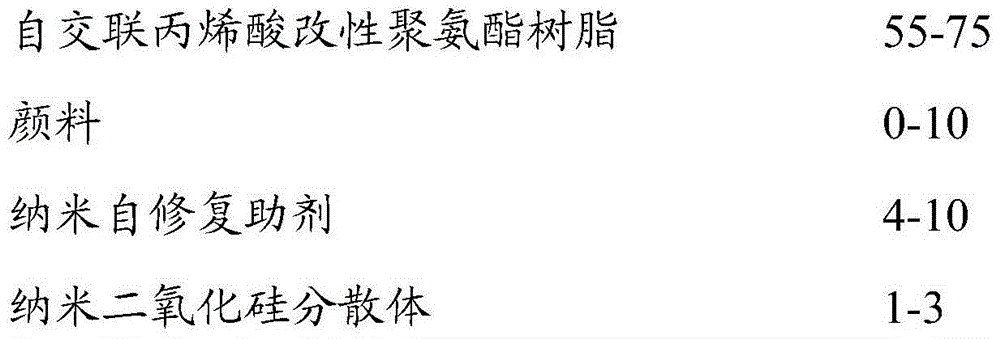

[0037] This embodiment consists of the following raw materials (feeding according to the following weight ratios):

[0038]

[0039] The above materials are used to prepare the self-repairing water-based wood topcoat through the conventional mixing process of the water-based paint.

[0040] The obtained topcoat has the advantages of high hardness, good elasticity, self-repairing micro-cracks, high gloss, good weather resistance, etc., and is simple to operate, easy to construct, environmentally friendly and efficient, and is a new high-performance environmentally friendly wood coating material.

Embodiment 2

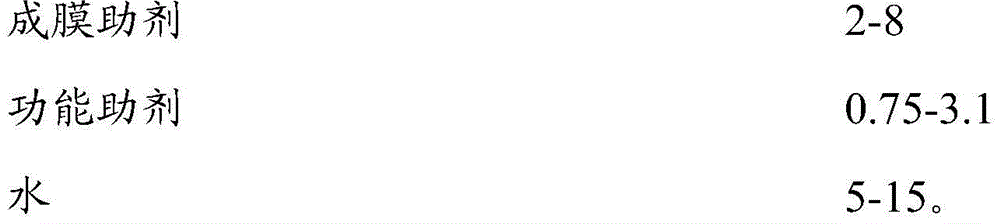

[0042] The present embodiment is made up of following raw material (according to following weight ratio):

[0043]

[0044] The self-repairing water-based wood paint is prepared by using the above materials through the conventional mixing process of the water-based paint.

[0045] The resulting topcoat has the advantages of high hardness, good elasticity, self-repairing of small scratches, high gloss, good weather resistance, etc., and is simple to operate, easy to construct, environmentally friendly and efficient, and is a high-performance new material for environmentally friendly wood coating.

Embodiment 3

[0047] The present embodiment is made up of following raw material (according to following weight ratio):

[0048]

[0049] The above materials are used to prepare the self-repairing water-based wood topcoat through the conventional mixing process of the water-based paint.

[0050] The resulting topcoat has the advantages of high hardness, good elasticity, self-repairing of small scratches, high gloss, good weather resistance, etc., and is simple to operate, easy to construct, environmentally friendly and efficient, and is a high-performance new material for environmentally friendly wood coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com