A rubber composition and tire using the same

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., to achieve the effect of improving hardness and anti-vulcanization reversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

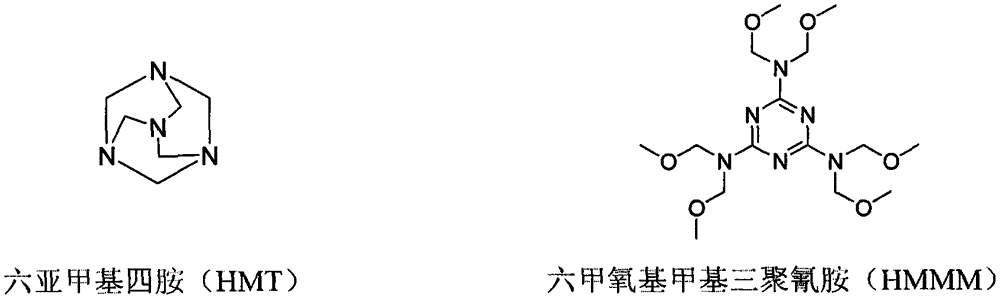

Method used

Image

Examples

Embodiment Construction

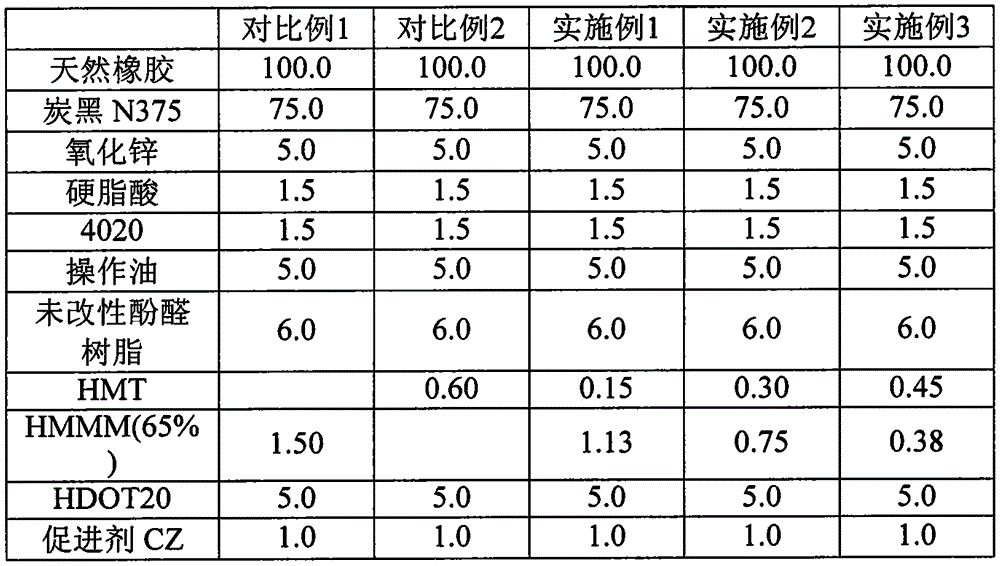

[0033] The present invention will be further explained below with examples, but the scope of the present invention is not limited to these examples, of course.

[0034] sample preparation

[0035] According to the formula shown in Table 1, with a 1.6 liter Banbury mixer, rubber, carbon black, and other compounds except sulfur, methylene donor and vulcanization accelerator were mixed for 6 minutes to obtain a masterbatch, and then A vulcanization accelerator, a methylene donor, and sulfur were mixed in a master batch using an open rubber mill to obtain rubber compositions, and each rubber composition thus obtained was vulcanized at a temperature of 150° C. for 30 minutes to obtain vulcanized rubber.

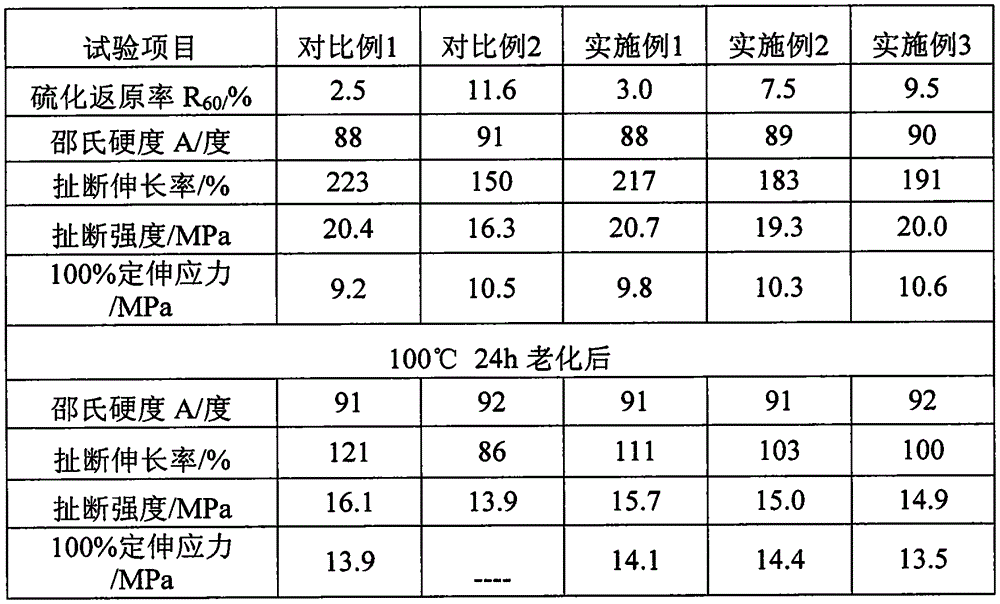

[0036] Anti-reversion performance

[0037] In accordance with GB / T 16584-1996, the test method for measuring vulcanization characteristics with a rotorless vulcanizer, measure the vulcanization reversion rate at 150°C for 60 minutes, and the anti-vulcanization reversion rate is ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com