Rapid-separation aerator dispersion disc for cable production sewage treatment

A technology for producing sewage and dispersing discs, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. It can solve the problems of low efficiency of dissolved air, improve efficiency and prevent clogging of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

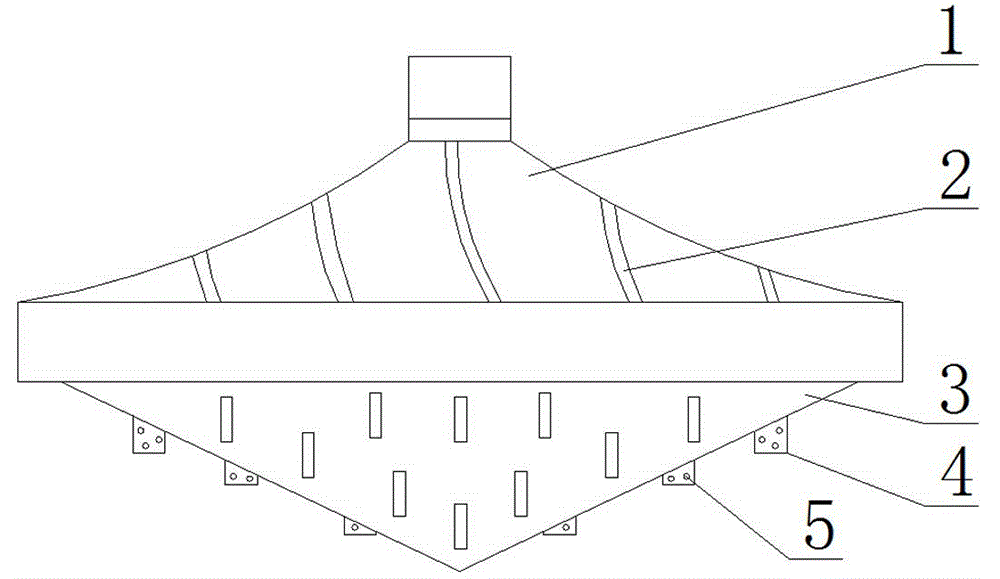

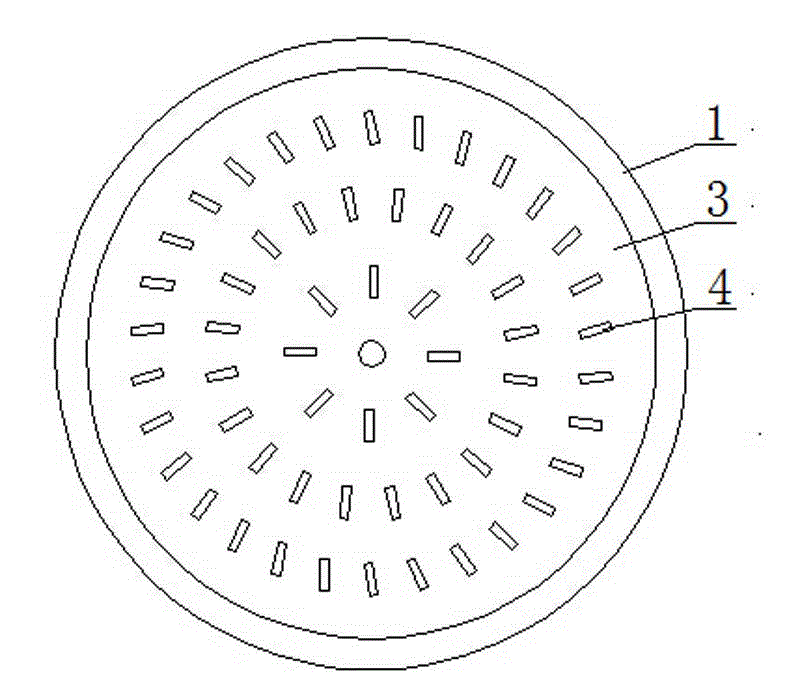

[0028] According to the quick-separation aerator dispersing disc used for cable production sewage treatment in this embodiment, the upper surface of the dispersing disc is uniformly provided with a plurality of arc-shaped guide strips, and the lower surface of the dispersing disc is provided with a stirring device. The stirring device comprises a conical base, the bottom surface of the base is connected to the lower surface of the dispersing disc, the outer wall of the base is connected with a stirring plate, the central axis of the base is on the plane where the stirring plate is located, The stirring piece is also provided with a plurality of through holes.

Embodiment 2

[0030] According to the quick-separation aerator dispersing disc used for cable production sewage treatment in this embodiment, the upper surface of the dispersing disc is uniformly provided with a plurality of arc-shaped guide strips, and the lower surface of the dispersing disc is provided with a stirring device. The stirring device comprises a conical base, the bottom surface of the base is connected to the lower surface of the dispersing disc, the outer wall of the base is connected with a stirring plate, the central axis of the base is on the plane where the stirring plate is located, The stirring plate is also provided with a plurality of through holes; the through holes are staggered on the stirring plate.

Embodiment 3

[0032] According to the quick-separation aerator dispersing disc used for cable production sewage treatment in this embodiment, the upper surface of the dispersing disc is uniformly provided with a plurality of arc-shaped guide strips, and the lower surface of the dispersing disc is provided with a stirring device. The stirring device comprises a conical base, the bottom surface of the base is connected to the lower surface of the dispersing disc, the outer wall of the base is connected with a stirring plate, the central axis of the base is on the plane where the stirring plate is located, The stirring plate is also provided with a plurality of through holes; the through holes are staggered on the stirring plate. The through holes are obliquely opened on the stirring plate, and the inclination angles between adjacent through holes are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com