Multi-station round pressing round hot stamping anodized aluminum synchronous roll changing and automatic marking integrated device

A technology of automatic marking and round pressing, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as low stability and reliability of equipment, large differences in joint positions, unfavorable joint detection work, etc. , to achieve the effect of ensuring the success rate of roll change, improving control accuracy and reducing the risk of quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

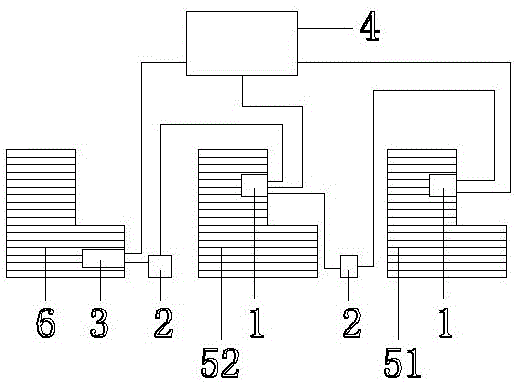

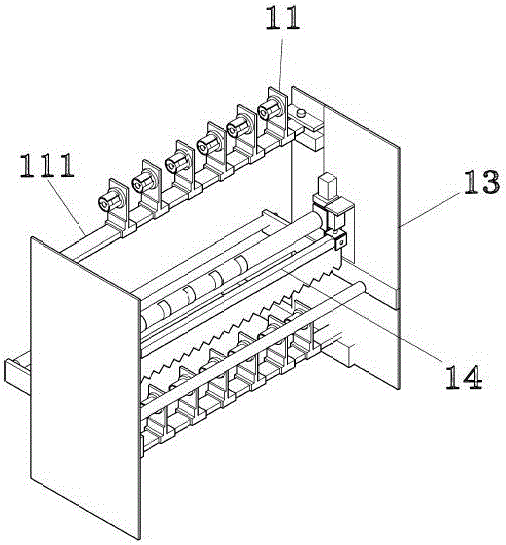

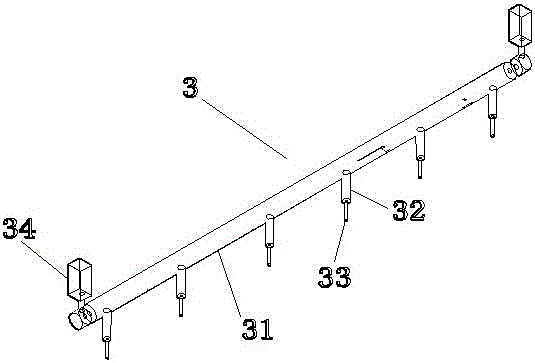

[0040] Such as Figure 1-12 As shown, the equipment described in this embodiment is an integrated device for golden and red hot stamping, simultaneous roll changing of six rolls of anodized aluminum, and automatic marking.

[0041] It includes two synchronous roll changing mechanism 1 and delay start device 2 composed of unwinding device 11, pre-fixing device 12 to be changed, wall panel 13 and delay cutting device 14, and also includes automatic identification mechanism 3 and main controller 4. The synchronous roll changing mechanism 1 is set on the first hot stamping station 51 and the second hot stamping station 52 respectively, the automatic identification mechanism 3 is set on the substrate winding station 6, and there are The delay start device 2 is connected with the main controller 4; the unwinding device 11, the pre-fixing device 12 to be changed and the delay cutting device 14 are all installed on the wallboard 13; the unwinding device 11 is at the uppermost end, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com