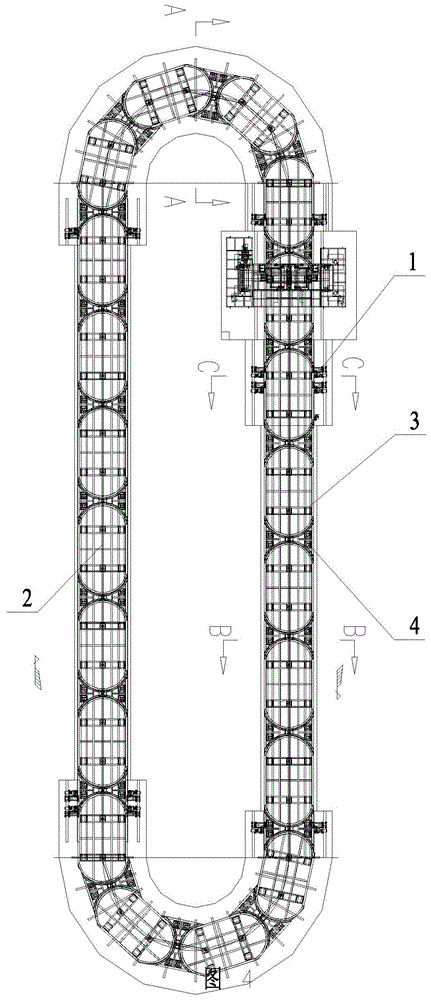

Arc-shaped slide plate conveyor line

A conveying line and arc-shaped technology, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing investment costs, equipment failure points, multiple equipment failure points, and oily chains, etc., to achieve low noise, Low investment cost and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

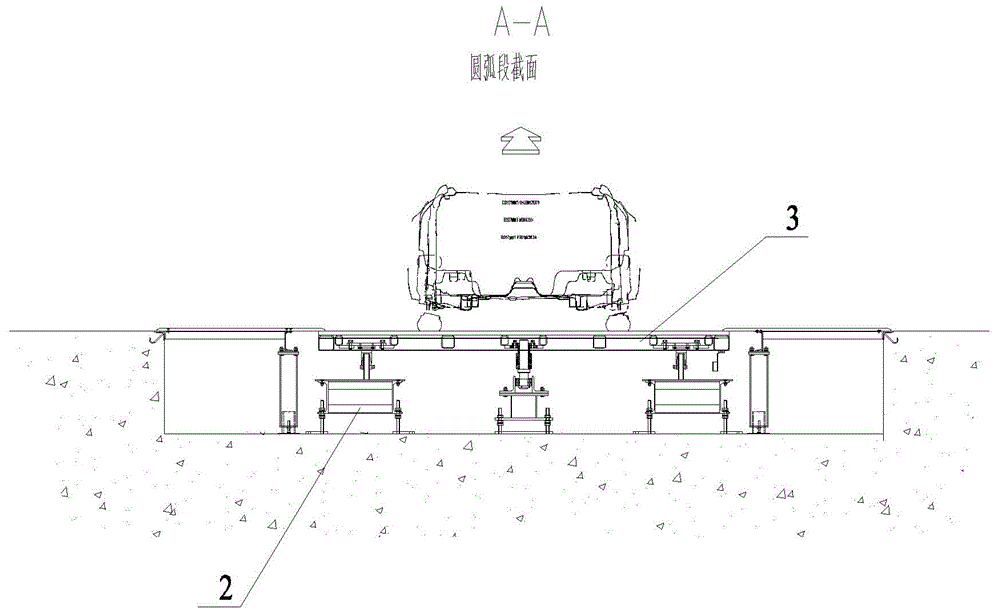

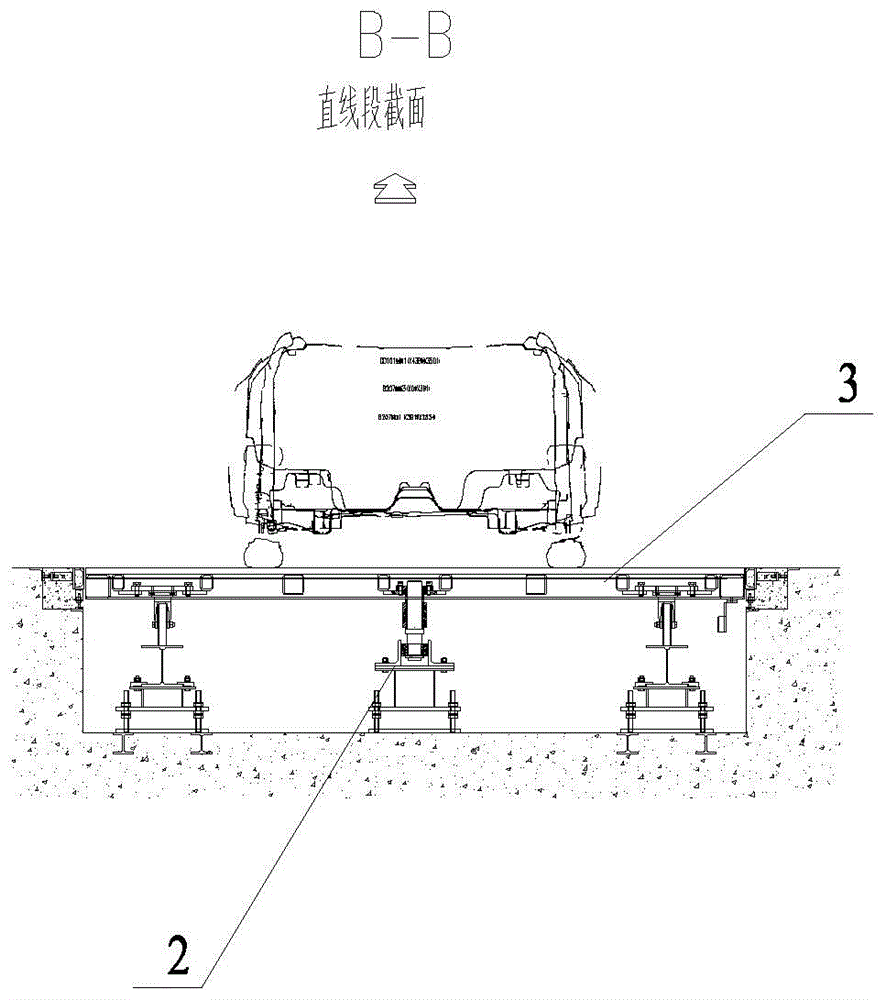

[0027] The curved slide conveyor line is fixed with an annular bearing rail 11 and an annular guide rail 12 on the frame, the bearing rail 11 cooperates with the guide rail 12, and the friction drive device 1 is fixed on the frame, sliding on the bearing rail 11 There are several arc-shaped skateboards 3 connected, and two adjacent arc-shaped skateboards 3 are connected by a skateboard connection device 4, and the arc-shaped skateboards 3 cooperate with the friction drive device 1; when working, the arc-shaped slide plates 3 are driven by the friction drive device 1 Run along the bearing track 11 under the guidance of the guide track 12 .

[0028] Described friction driving device 1 comprises friction wheel 5, movable support 6, fixed support 7, motor speed reducer 8, flat key 9 and adjustment spring 10; The motor reducer 8 is fixed with a friction wheel 5 through a flat key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com