Intelligent express sorting vehicle

An intelligent, car-driven technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of large floor space, high error rate, poor mobility, etc., to achieve small floor space, development assistance, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

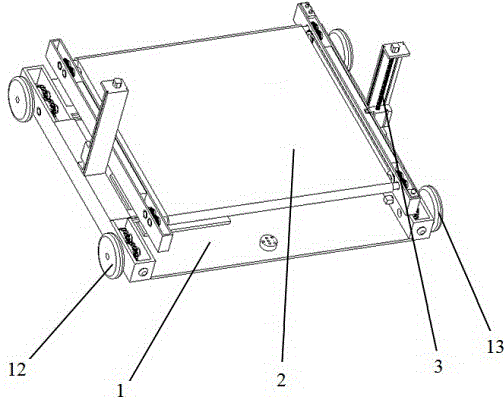

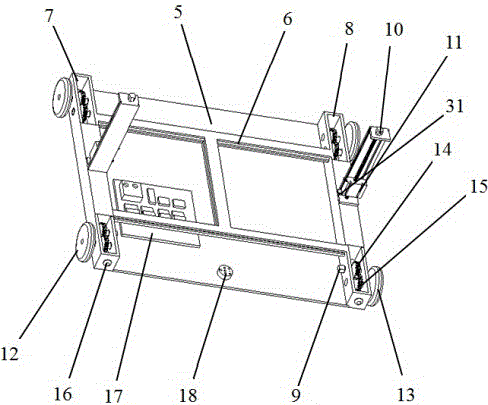

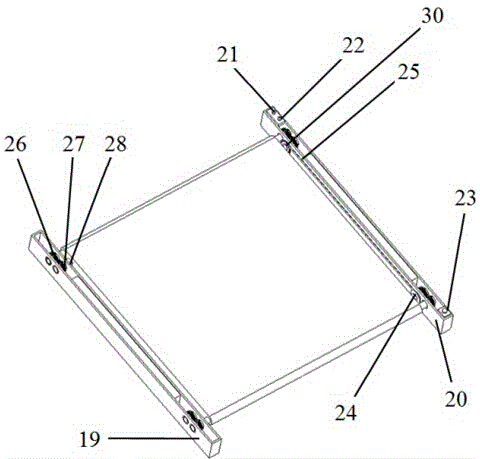

[0022] like figure 1 , 2 , 3, 4 and 5, the intelligent express delivery sorting vehicle of the present invention includes a drive vehicle 1 and a transmission device 2 located above the drive vehicle 1; Shaped ribs 6, the shown I-shaped ribs 6 are used to carry the conveyor belt, the driving left frame 7 and the driving right frame 8 respectively connected to the I-shaped ribs 6, respectively connected to the driving left frame 7 and the driving right frame 8 Two wheels, drive motor 9, pressure sensor 31 and photoelectric sensor 16 located on the lead screw device driving left frame 7 and driving right frame 8, control device 17, buzzer 18 and photoelectric sensor located on base 5 The track module 4 is provided with a Hall element 29 on the wheel; the drive left frame 7 and the drive right frame 8 are provided with an engaged drive main gear 14 and a drive pinion 15, and the drive main gear 14 is connected to the drive motor 9 ; The lead screw device comprises a leading sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com