Pipe packing machine

A packaging machine and pipe technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of high production cost, affecting pipe packaging, slow speed, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

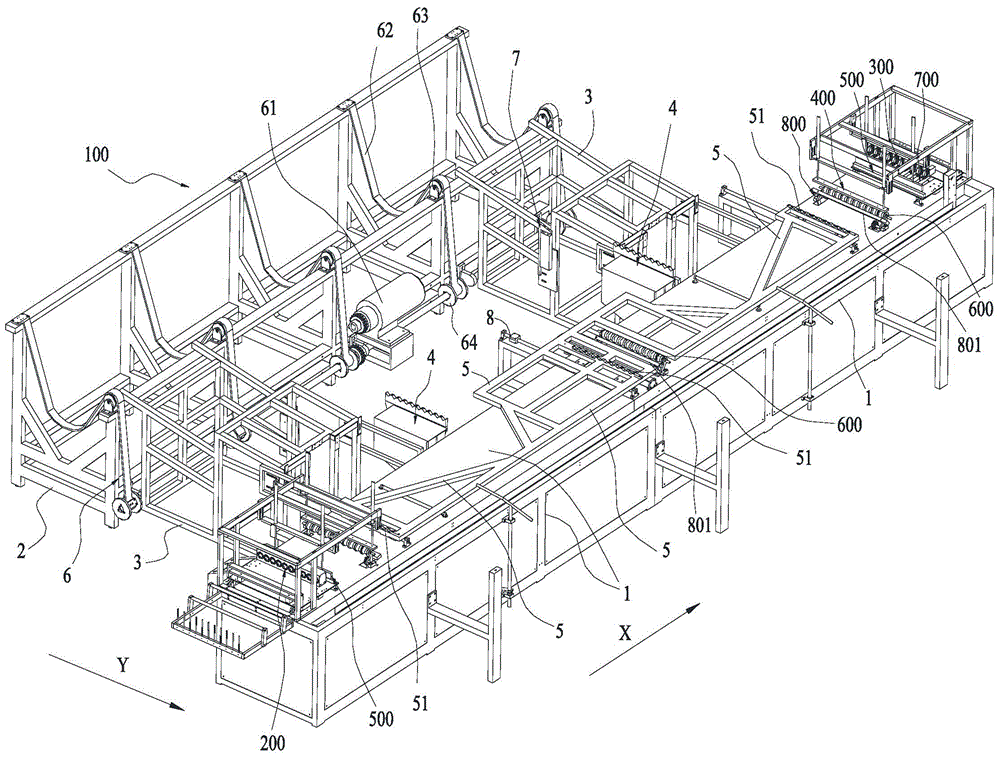

[0045] Such as figure 1 The tube packaging machine shown includes: a frame 1, an automatic feeding device 100, a magnetic partition type film penetration device 200, a film clamping device 300, a pressing device 400 and a sealing device 500, wherein:

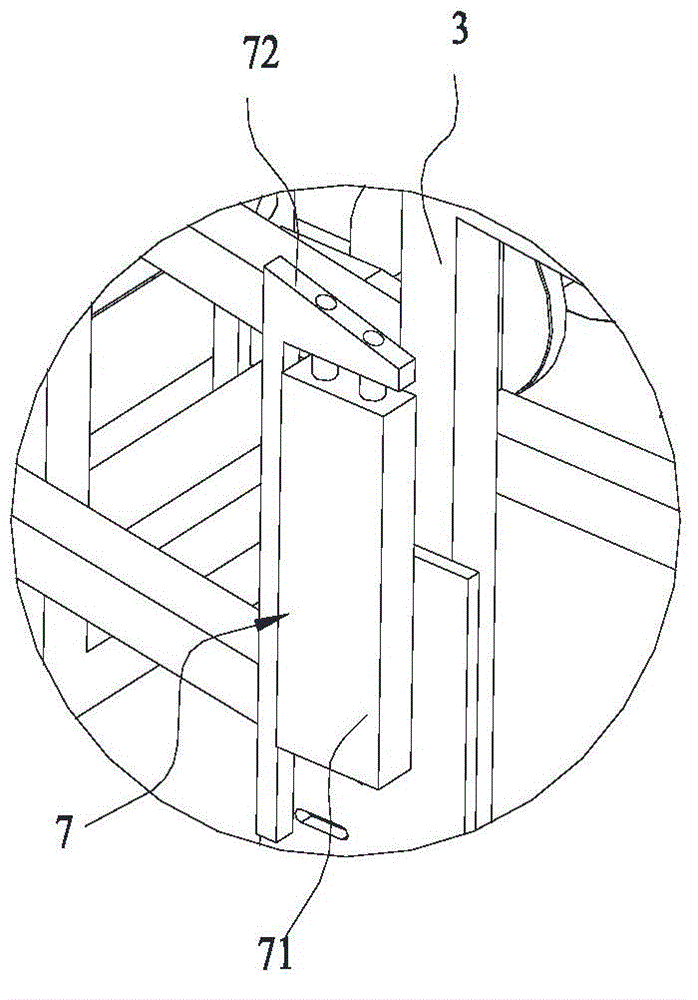

[0046] Frame 1, the frame 1 is equipped with a driving support wheel 600 for supporting the limit pipe and driving the packaging film on the pipe to move along the rear and a positioning device 700 for positioning the rear end of the pipe;

[0047] The automatic feeding device 100 is used to transport the pipe material to the active supporting wheel 600 for support;

[0048] The magnetic-separated film penetration device 200 is installed on the front end of the frame 1, and is used to stretch the packaging film and set it on the front end of the pipe and to position the front end of the pipe;

[0049] The film clamping device 300 slides along the front and back direction of the frame 1, and is used to clamp the packaging film s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com