Low-noise hydraulic steering gear

A hydraulic steering gear, low-noise technology, applied in the direction of steering mechanism, fluid steering mechanism, power steering mechanism, etc., can solve the problems of complicated flow path, high noise of steering gear, and affecting the quality of steering gear, so as to reduce noise, flow speed and The effect of soft pressure changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

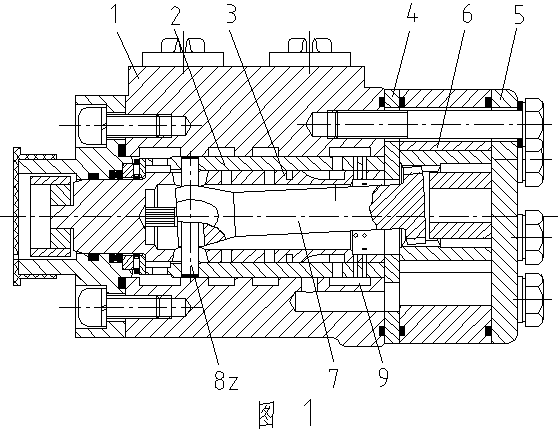

[0030] The low-noise hydraulic steering gear of this embodiment is as figure 1 As shown, its basic structure is the same as the prior art, and the right end of the valve body is equipped with a cycloidal pinwheel engagement pair 6 between the partition plate 4 and the back cover 5 . The inner hole of the valve body 1 has a valve body oil inlet ring groove 9 and is installed with an indexable valve core 3 with a flow channel through the valve sleeve 2, or in other words, the valve hole of the valve body 1 is equipped with a valve sleeve 2 and a cartridge Indexable spool 3 in the valve sleeve. The valve core 3 is equipped with a linkage shaft 7, and one end of the linkage shaft 7 is respectively connected with the valve sleeve 2 and the valve core 3 through the dial pin 8 and the elastic member to form a rotary valve flow distribution mechanism matched with the flow channel of the valve body 1. The other end of the linkage shaft 7 is connected to the cycloidal pinwheel meshing ...

Embodiment 2

[0036] The basic structure of the low-noise hydraulic steering gear of this embodiment is the same as that of Embodiment 1. The difference is the specific structure of the valve sleeve 2 and the valve core 3 .

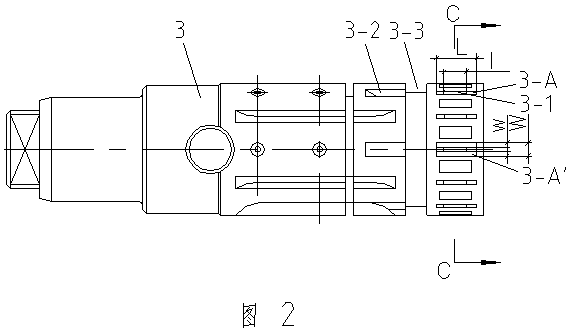

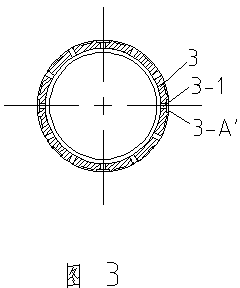

[0037] The valve sleeve 2 of the present embodiment is as Figure 4 and Figure 5 shown, see Figure 9 , Figure 9' , one end has a set with figure 1 Two rows of 12 pairs of radial valve sleeve oil return groove holes 2-1 corresponding to the right side of the valve body oil inlet ring groove 9 of the middle valve body 1 are distributed at circumferential intervals. Each valve sleeve oil return groove hole 2-1 is made of round counterbore 2-1-1 and the slot 2-1-2 at the bottom of round counterbore. The outer mouth of each pair of round counterbore 2-1-1 is shaped on the accumulator 2-1-3 of circular arc bottom. The slot 2-1-2 of the oil return groove hole 2-1 of the valve sleeve is formed with an arc bottom buffer groove 2-A whose axial extension length L is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com