Structure for connecting solar panel with automobile body on solar car

A solar panel and connection structure technology, applied in the automotive field, can solve the problems of reducing the service life of the lighting panel and accelerating the aging of the lighting panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The shape of this solar car is no different from existing cars (such as a kind of car [application number: 2007300814706, publication number: 300870593] disclosed in the Chinese Patent Library).

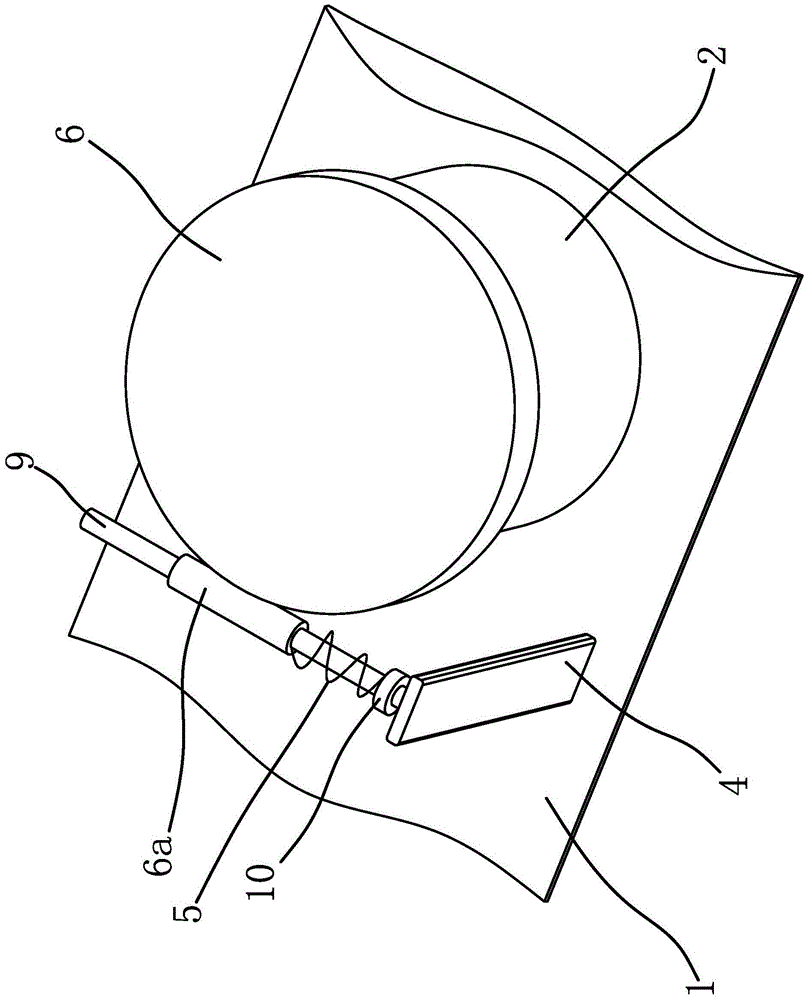

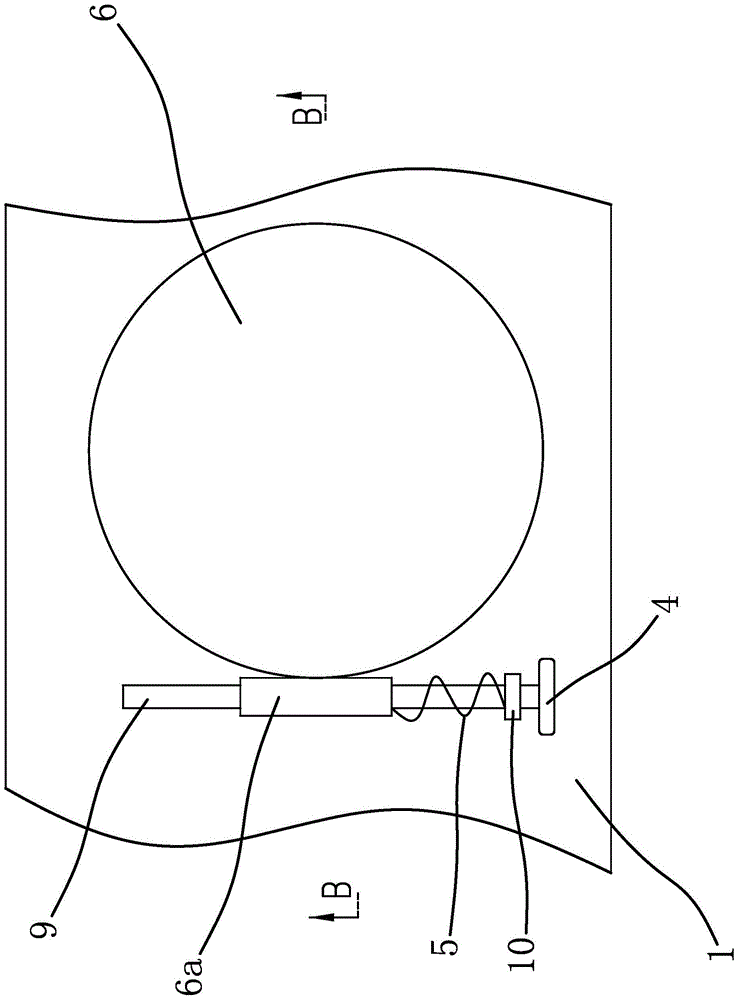

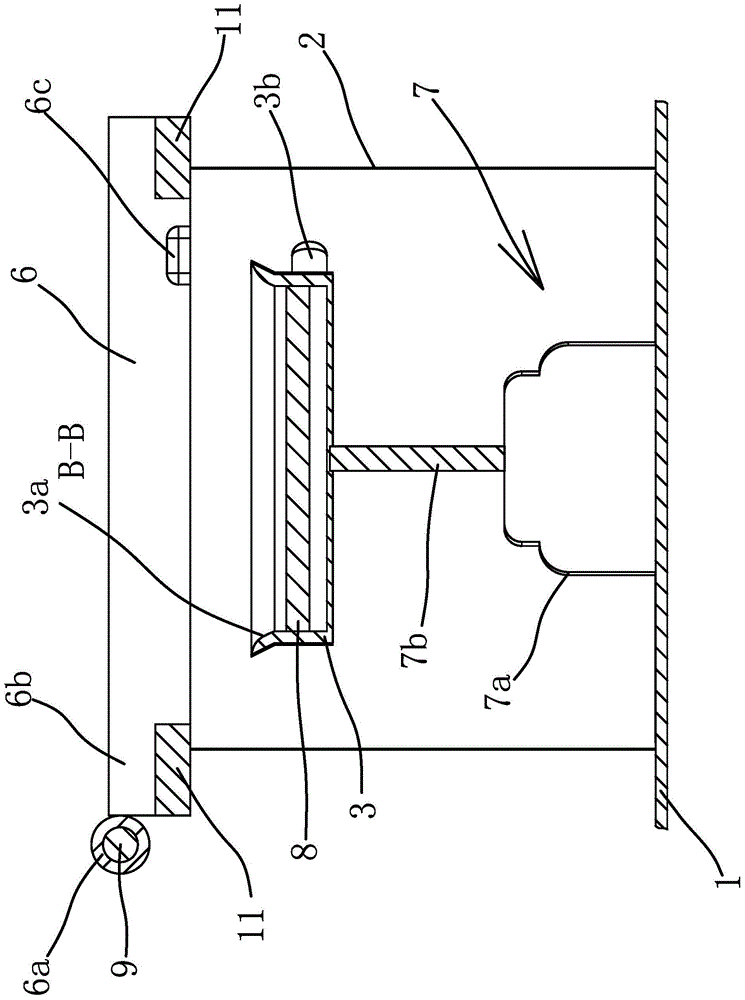

[0050] The solar car comprises a car body 1, such as figure 1 , figure 2 and image 3 As shown, the connection structure between the solar panel and the automobile includes a connection part 2, a mounting plate 3, a connection column 4, a torsion spring 5, a driving part, a sealing plate 6 and the like.

[0051] Wherein, the connecting part 2 is cylindrical and fixed vertically on the top of the vehicle body 1 , and the connecting column 4 is vertically arranged on the vehicle body 1 and is located on the side of the connecting part 2 . In this embodiment, the connecting post 4 is long, and the connecting post 4 and the connecting part 2 are fixed on the top of the vehicle body 1 by welding, which has the advantage of making the connecting post 4 and the connecting part 2 f...

Embodiment 2

[0067] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the inside of the sealing plate 6 has a protruding and annular sealing cylinder, the sealing cylinder is opposite to the mounting plate 3 and the sealing cylinder The inner diameter is larger than the outer diameter of the mounting plate 3, and there is an annular groove on the outer edge of the sealing cylinder. The sealing structure includes an O-shaped sealing ring located in the annular groove, and the outer peripheral surface of the O-shaped sealing ring is connected to the connecting part 2 The inner edges are offset. The sealing cylinder is annular and the mounting disk 3 is cylindrical. When the inner diameter of the sealing cylinder is larger than the outer diameter of the mounting disk 3, that is, when the mounting disk 3 translates upwards under the action of the driver, the mounting disk 3 will enter the connecting part 2, so that the sea...

Embodiment 3

[0069] The structure and principle of the third embodiment are basically the same as those of the first embodiment, except that the driving part is a rotating motor, the rotating motor is fixed on the top of the car body 1 and is located in the connecting part 2, and the end of the output shaft of the rotating motor is fixedly connected There is a screw mandrel, and a nut is screwed on the screw mandrel and the end face of the nut is connected with the bottom of the mounting plate 3 . When working, the rotating motor starts the rotation of the output shaft of the rotating motor to drive the screw to rotate. Since the nut is threaded on the screw, when the screw rotates, the nut converts the circumferential rotation relative to the axis of the output shaft of the rotating motor into a horizontal rotation relative to the axis. The axial movement drives the mounting plate 3 to translate up and down. Through the above design, it has the advantages of simple structure and convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com