Heat insulation and preservation structure of hot plate welding mold

A hot plate welding, thermal insulation technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of heat loss, high energy consumption, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

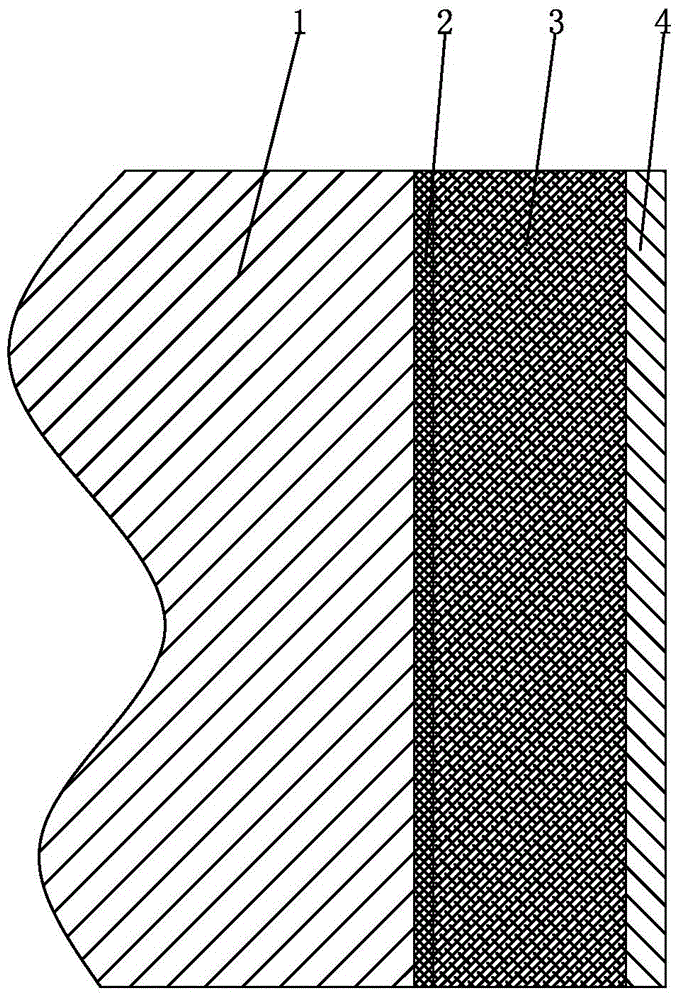

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , a thermal insulation structure of a hot plate welding mold, including a thermal insulation aluminum foil 2, a thermal insulation asbestos 3 and an outer protective layer 4, the thermal insulation aluminum foil 2 with a thickness of 0.02-0.2mm is first selected during production, and the aluminum foil is required The long-term use temperature reaches above 600 degrees, one side is backed with high temperature resistant glue, and then it is tightly pasted on the non-working part 1 of the hot plate welding mold hot mold, one layer is enough, and the installation hole should be left out; then according to the environmental protection , flame retardant, and temperature-resistant requirements, select heat-insulating asbestos 3 with a thickness of 2-5mm, and cut it according to the shape of the hot mold so that it can well cover the non-working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com