High-efficiency integrated rolling station

A high-efficiency, rolling technology, applied in the field of tire building, can solve the problems of low production and processing efficiency, poor specification adaptability, etc., and achieve the effect of saving time, improving speed and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

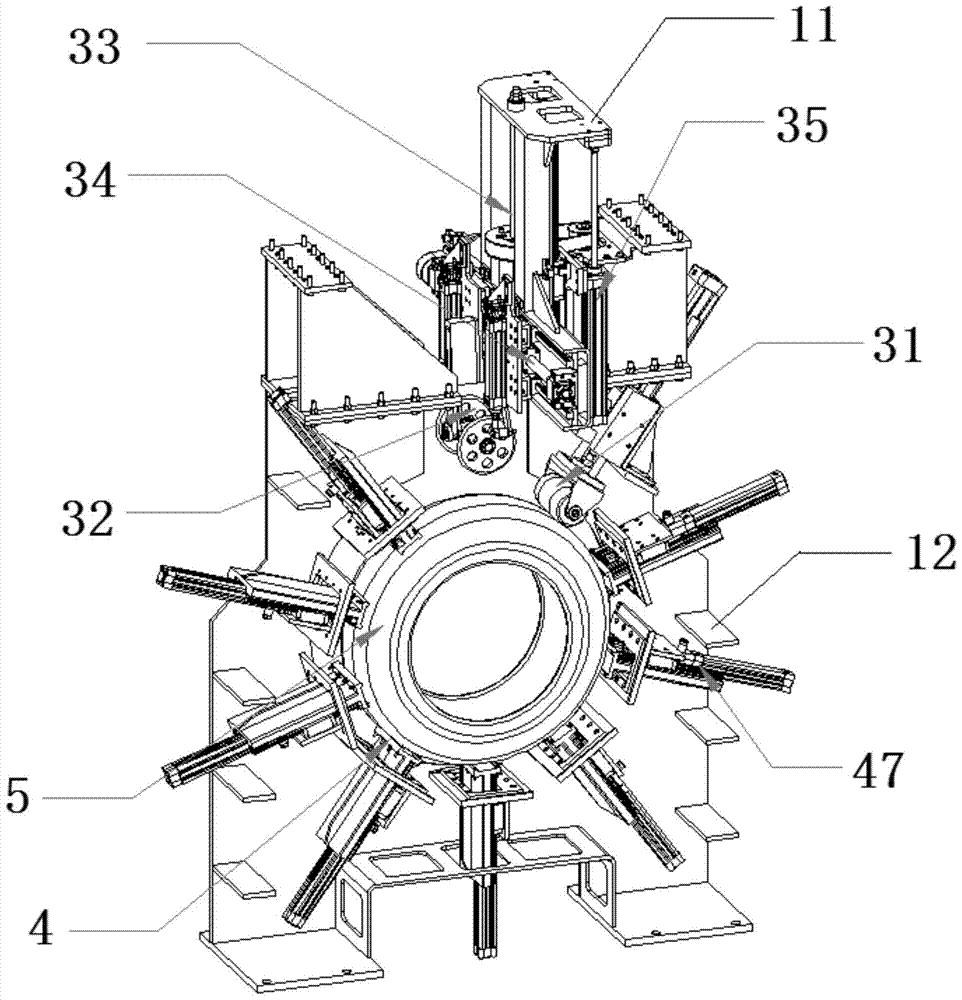

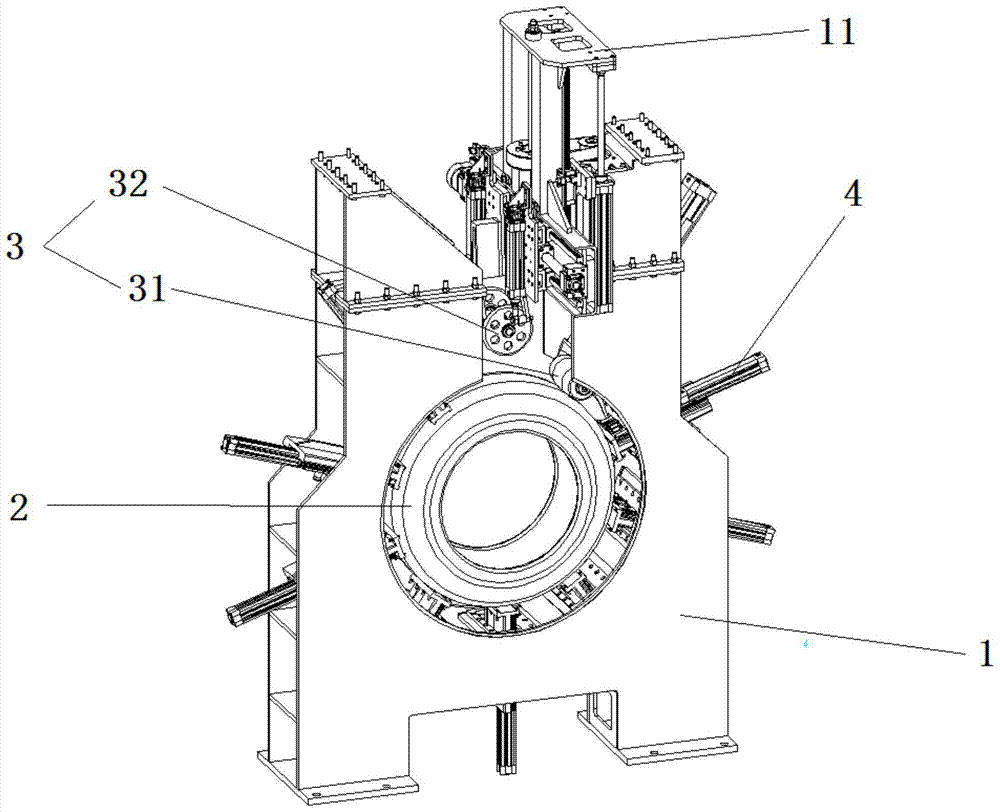

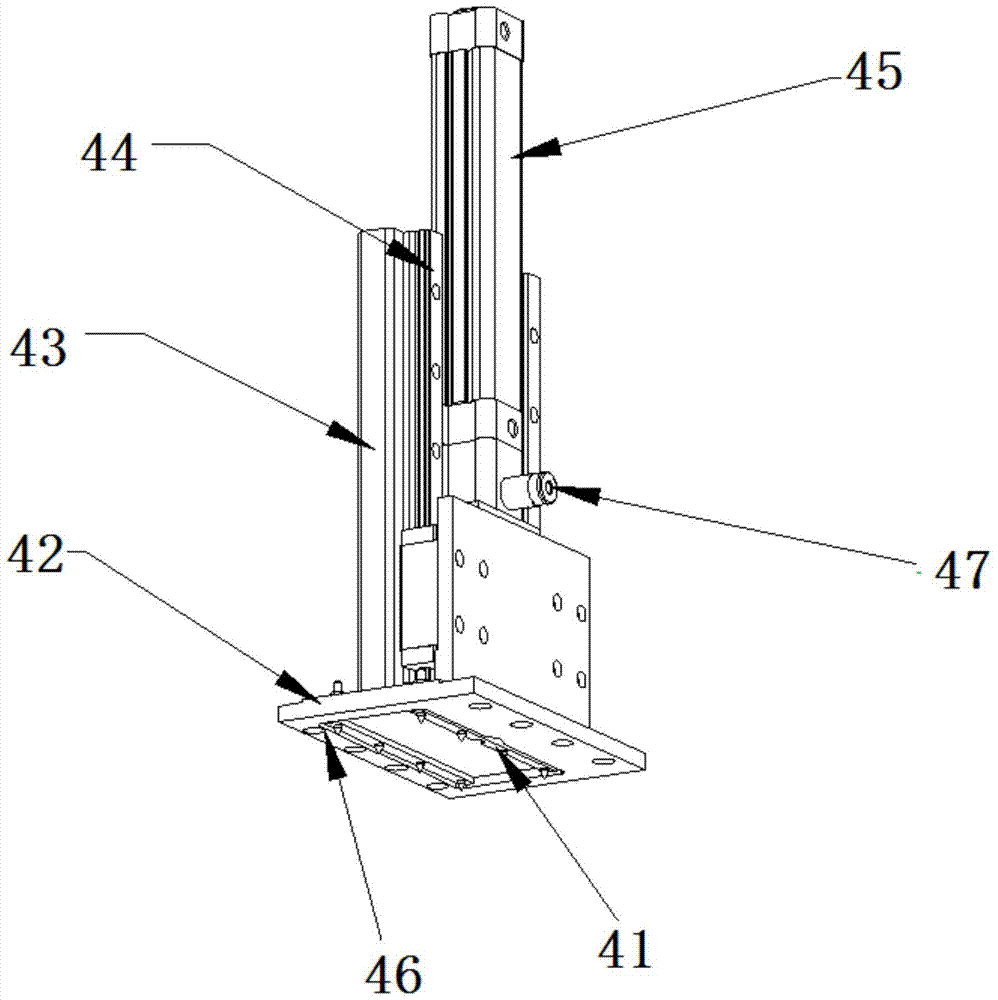

[0024] Such as Figure 1 to Figure 3 As shown, a high-efficiency integrated rolling station according to the present invention includes a rolling station body 1, a transfer ring 2 and a combined pressing roller 3 arranged on the rolling station body 1, wherein the transfer ring 2 It includes multiple groups of grippers 4, each of which is provided with an edge 41, and the combination of the edges 41 of the plurality of groups of grippers 4 forms a hollow ring structure, which is located at the rolling station In the middle of the body 1 , the annular structure is approximately circular, and is used to place a product 5 therein and be clamped by the gripper 4 , and the product 5 includes but is not limited to. The transfer ring 2 can be driven by a servo motor for precise positioning. The gas structure of the transfer ring 2 is composed of a welded stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com