Pressable Hole Stapler

A stapler and hole needle technology, which is applied in staple tools, metal processing, nailing tools, etc., can solve the problems of inability to bind, staples cannot be bent, complex structure, etc., and achieve simple and reasonable structure, secure The effect of reliability and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

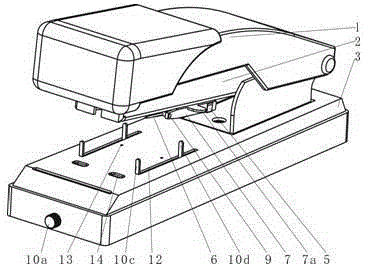

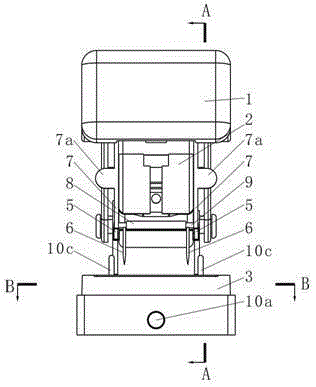

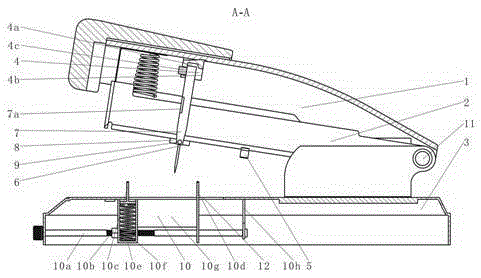

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the pressing handle 1 and the needle storage box 2 are hinged on the base 3 through the base pin 11 . The shaft hole plate 8 is an elongated plate with a through hole in the length direction, the hole axis is perpendicular to the side wall of the needle storage box 2, and is connected to the bottom surface of the needle storage box 2 near the front end. The rotating shaft 9 passes through the through hole of the shaft hole plate 8 . There are two pressing pins 6, and the spacing between the two pressing pins 6 is the same as the spacing between the two pins of the staple, and they are connected in parallel on the rotating shaft 9 protruding from the shaft orifice plate 8 both sides. There are two struts 7, which are rod-shaped parts, and are connected with breaking ears 7a, which are respectively connected to the two ends of the rotating shaft 9. The connected struts 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com