Tensioning clamp of elongated shaft

A slender shaft and fixture technology, which is used in clamping, manufacturing tools, toolholder accessories, etc., can solve the problems of large surface errors, poor smoothness, and poor accuracy of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

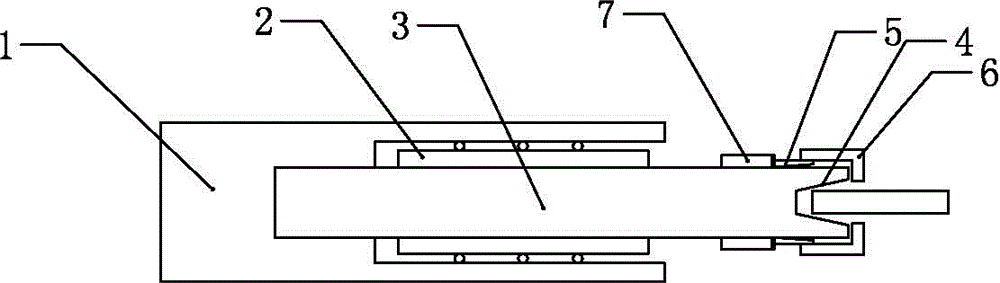

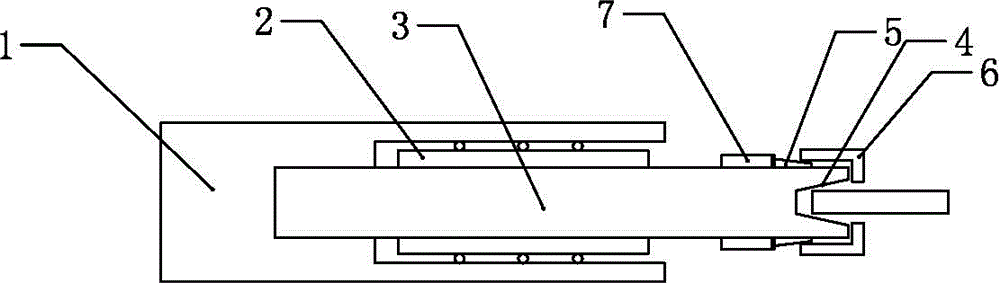

[0017] like figure 1 , image 3 As shown, the slender shaft tensioning fixture includes a clamping body, a tailstock main shaft 1 and an inner spacer 2. The tailstock main shaft 1 is sleeved outside the inner spacer sleeve 2 and between the inner spacer sleeve 2 and the tailstock main shaft 1 There is a bearing, the clamp body includes a mandrel 3, one end of the mandrel 3 is axially inserted into the inner spacer 2 and is threadedly connected with the inner spacer 2, and a positioning pin is used between the mandrel 3 and the inner spacer. The shaft 3 is coaxial with the tailstock main shaft 1; the other end of the mandrel 3 is axially provided with a circular truncated groove 4 for the slender shaft to be inserted into. The outer wall of the main shaft is provided with a set of shrinking grooves; the outer wall of the round table groove 4 is provided with a fixing sleeve 6, and a wedge-shaped sleeve 5 is arranged between the fixing sleeve 6 and the outer wall of the mandrel...

Embodiment 2

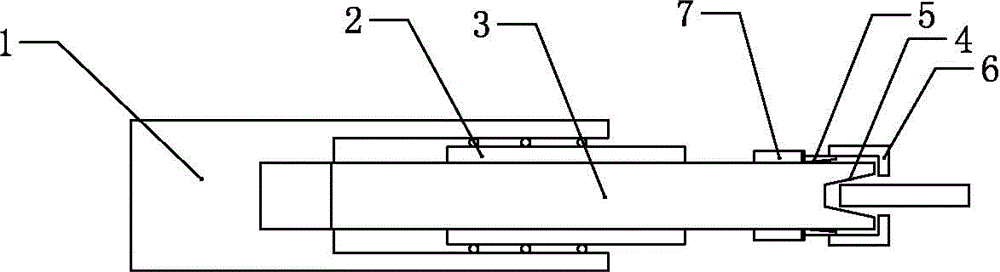

[0020] like figure 2 Shown: the inner hole diameter of the front end of the wedge-shaped sleeve 5 barrels in the first embodiment is larger than the rear end inner hole diameter, and the outer diameter of the front end of the wedge-shaped sleeve 5 barrels is consistent with the outer circle diameter of the rear end, and is replaced by: wedge-shaped sleeve 5 barrels The diameter of the inner hole of the front end is the same as that of the inner hole of the rear end, and the outer diameter of the front end of the wedge-shaped sleeve 5 is smaller than the outer diameter of the rear end.

[0021] The operation is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com