Three-dimensional laser marking method and device and three-dimensional laser machining equipment

A three-dimensional laser and processed technology, which is applied in the field of three-dimensional laser processing equipment, three-dimensional laser marking methods and devices, can solve the problems of high processing cost and expensive equipment, and achieve the effect of eliminating blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

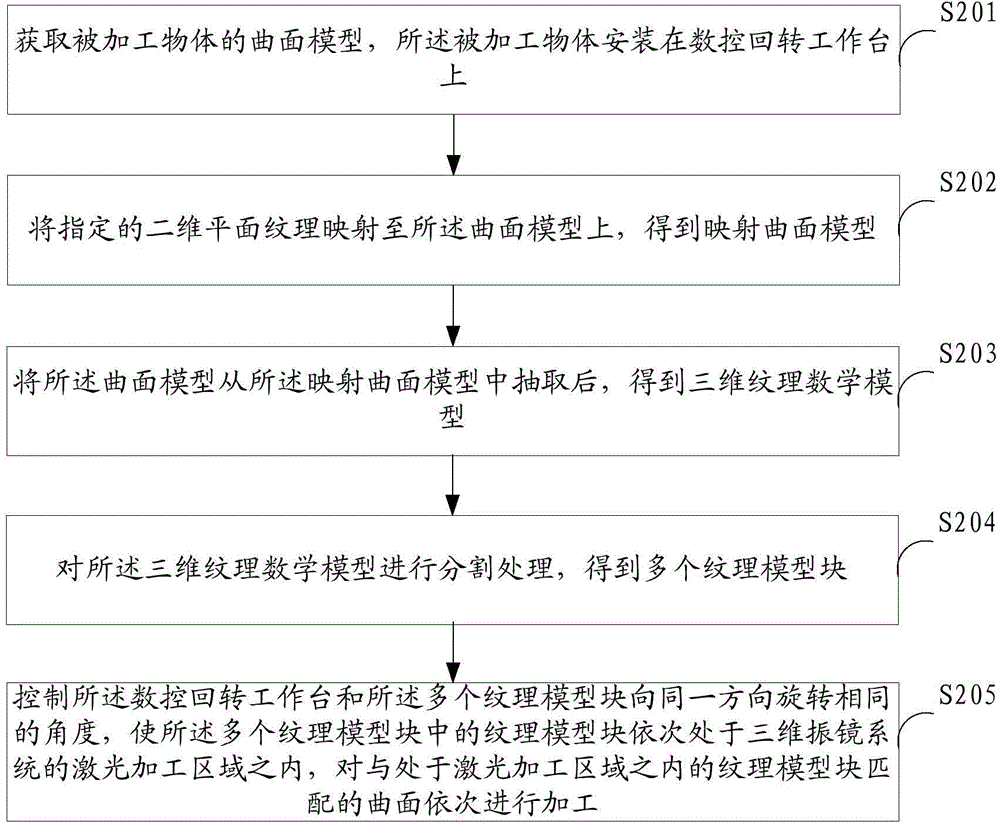

[0039] figure 2 A flow chart of the three-dimensional laser marking method provided by Embodiment 1 of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

[0040] In step S201, the curved surface model of the object to be processed is acquired, and the object to be processed is installed on a numerically controlled rotary table.

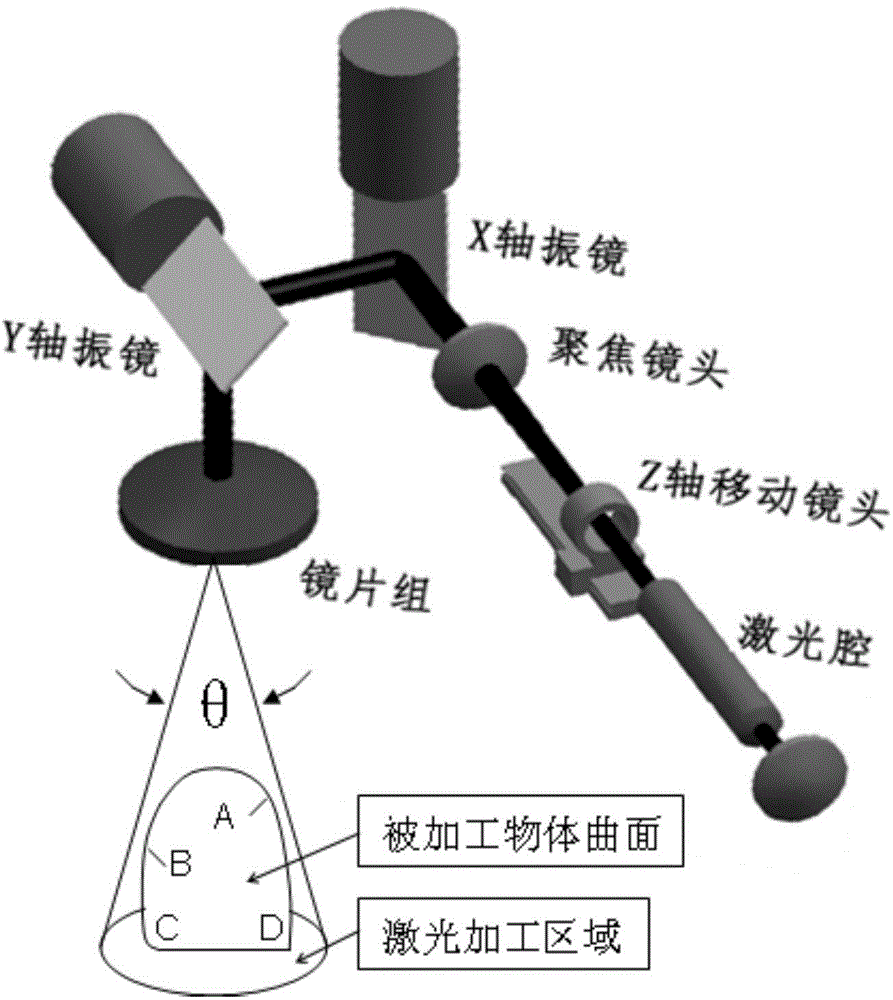

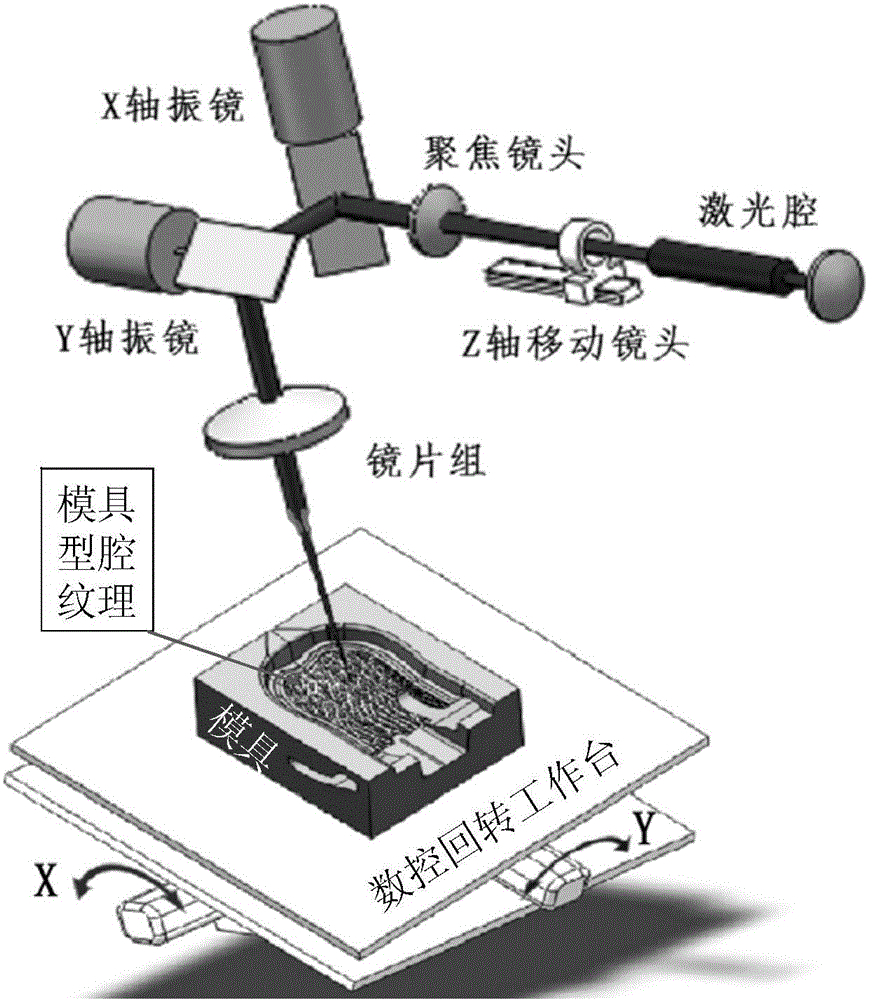

[0041] In the embodiment of the present invention, the three-dimensional laser processing equipment is equipped with a general-purpose three-axis numerical control movement 3D galvanometer system, such as figure 1 As shown, the three-dimensional vibrating mirror system includes a laser cavity, a Z-axis moving lens, a focusing lens, an X-axis vibrating mirror, a Y-axis vibrating mirror and a lens group. The laser output by the three-dimensional galvanometer system has a certain angle, and the laser action area is in the fi...

Embodiment 2

[0062] Figure 6 A structural block diagram of the three-dimensional laser marking device provided by Embodiment 2 of the present invention is shown, and for convenience of description, only parts related to the embodiment of the present invention are shown. The three-dimensional laser marking device 6 may be a software unit, a hardware unit or a combination of software and hardware built in the three-dimensional laser processing equipment. In this embodiment, the three-dimensional laser marking device includes: an acquisition unit 61 , a mapping unit 62 , an extraction unit 63 , a segmentation unit 64 and a marking unit 65 .

[0063] Wherein, the acquisition unit 61 is used to acquire the curved surface model of the object to be processed, and the object to be processed is installed on the CNC rotary table;

[0064] A mapping unit 62, configured to map a specified two-dimensional plane texture onto the curved surface model to obtain a mapped curved surface model;

[0065] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com