Soldering flux bracket for pile pipe submerged-arc soldering

A submerged arc welding and flux technology, applied in arc welding equipment, applications, household appliances, etc., can solve the problems of high labor intensity, low work efficiency, and lowering the level of pile pipe welding automation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

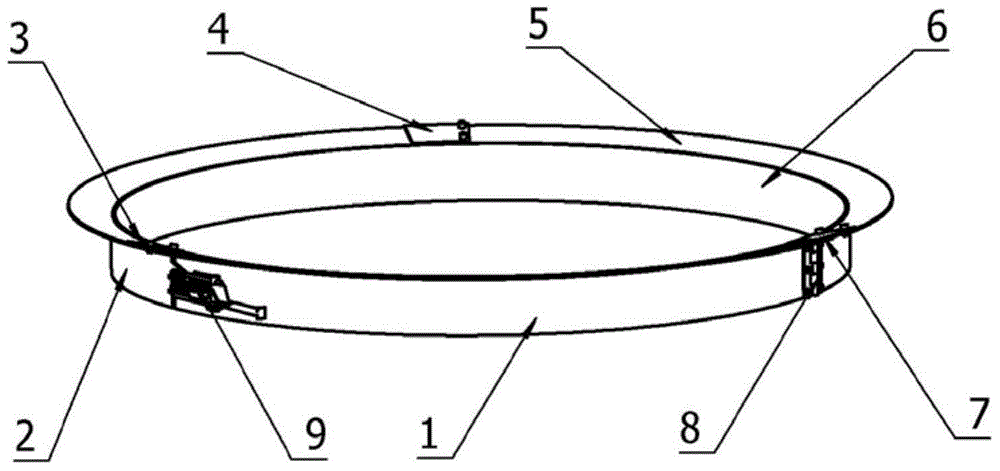

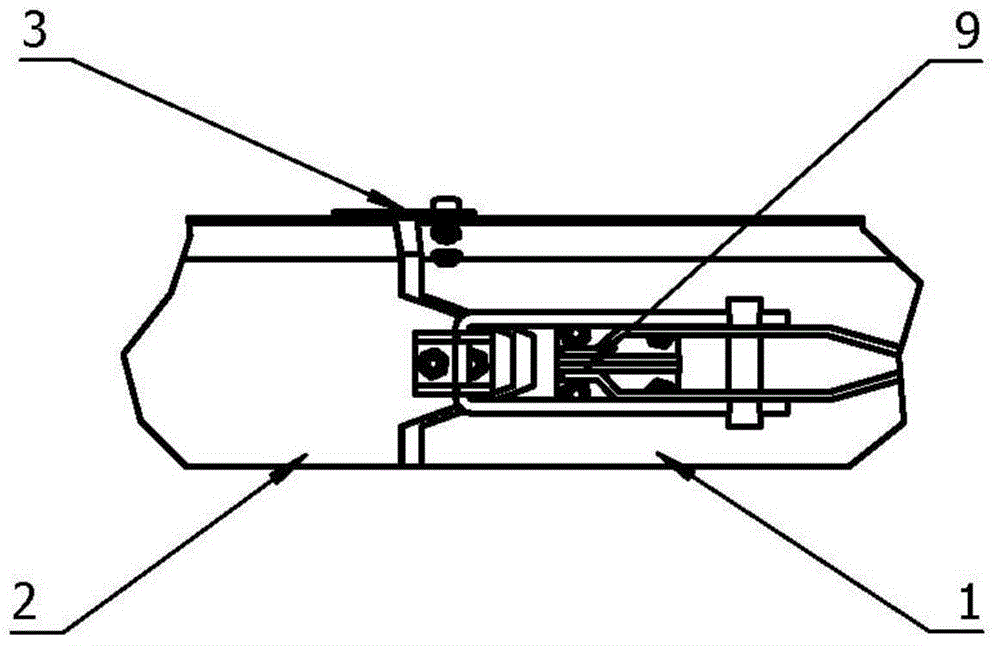

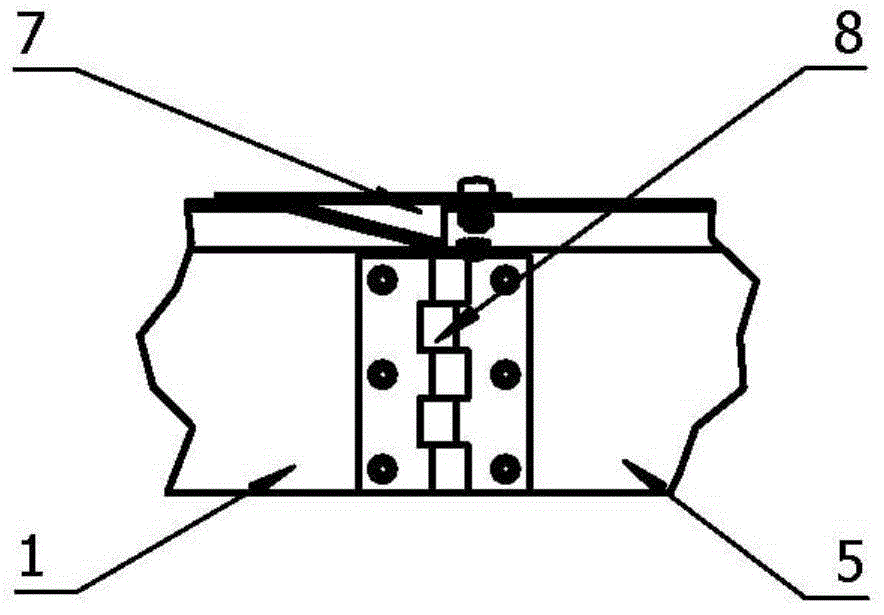

[0018] see Figure 1-3 , a flux bracket for pile pipe submerged arc welding provided by an embodiment of the present invention, comprising:

[0019] A first arc 1, the first arc 1 is in contact with the pile pipe;

[0020] A lock 9, the lock 9 is connected to the first arc 1;

[0021] The second arc ring 2, the second arc ring 2 is connected to the first arc ring 1 through the lock 9, and the first arc ring 1 is in contact with the pile pipe;

[0022] A first hinge 8, the first hinge 8 is connected to the first arc 1;

[0023] a second hinge, the second hinge is connected to the second arc ring 2;

[0024] A third arc 5, one end of the third arc 5 is connected to the first arc 1 through the first hinge 8, and the other end is connected to the second arc 2 through the second hinge ; The first arc circle 1, the second arc circle 2 and the third arc circle 5 form a ring structure; the ring structure is stuck on the pile pipe.

[0025] In order to introduce the embodiment of ...

Embodiment 2

[0035] In order to introduce the embodiment of the present invention more clearly, the following introduces it from the usage method of the embodiment of the present invention.

[0036] see Figure 4 First, the flexible track 11 is tightly hooped above the groove of the pile pipe; 2 sets of adjustable movable wheels and 2 sets of supporting walking wheels are respectively fixed on the four corners of the lower and upper sides of the bottom plate 17 with screws, and then The wheel grooves of the four wheels are clamped to the upper and lower edges of the flexible track 2, so that the bottom plate 17 is suspended on the flexible track 11, and the movable wheel and the supporting walking wheel are double-groove wheels, which can be passed smoothly at the joint of the flexible track 11. , and has the function of rotating in the radial direction, which can adapt to changes in the curvature of different pile tubes. The coupling is connected with the supporting walking wheel to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com