Parallel slot milling machine

A slot milling machine and milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of difficult processing of milling machines, hidden dangers of large-scale production safety, poor automatic performance of milling machines, etc., to reduce hidden dangers of production safety, Improvement of productivity and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

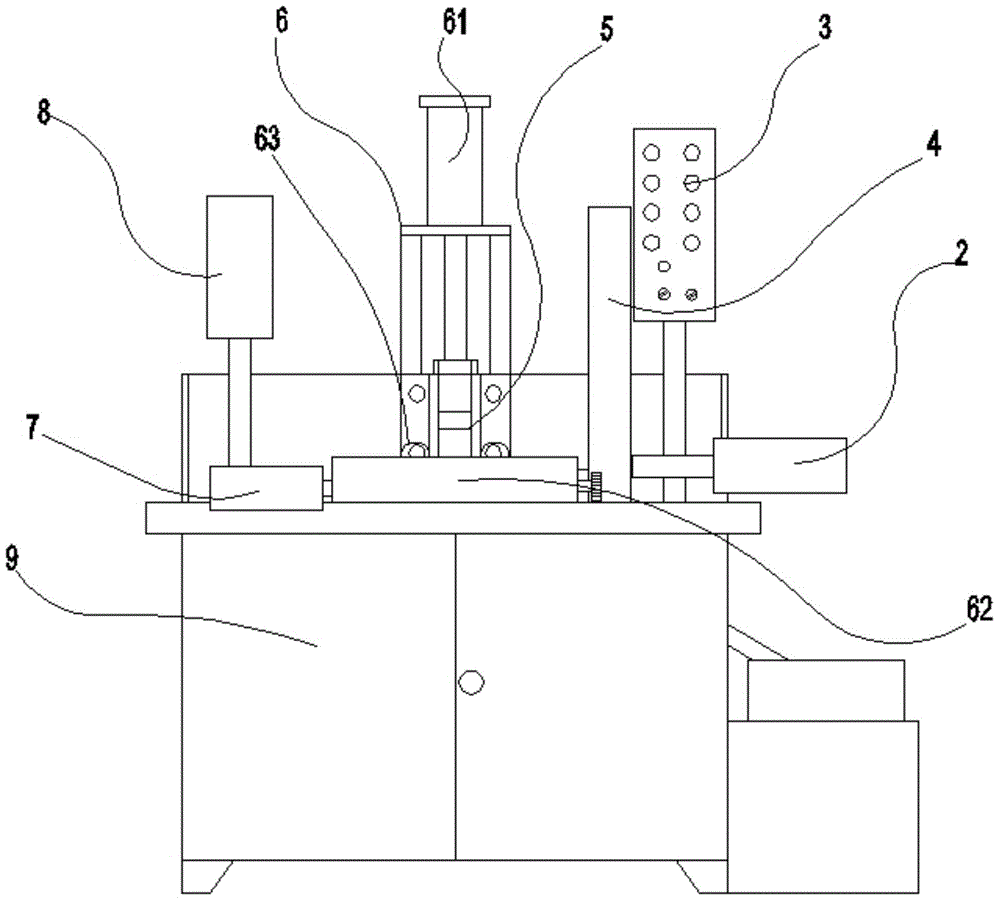

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] according to figure 2 , the present invention provides a parallel slot milling machine, including a workbench, on which a feeding mechanism (2), an electrical control box (3), a feeding mechanism (4), a clamping mechanism (5), and a milling mechanism ( 6), the material ejection mechanism (7) and the hydraulic valve group (8), and the milling head drive unit (9) is arranged under the workbench.

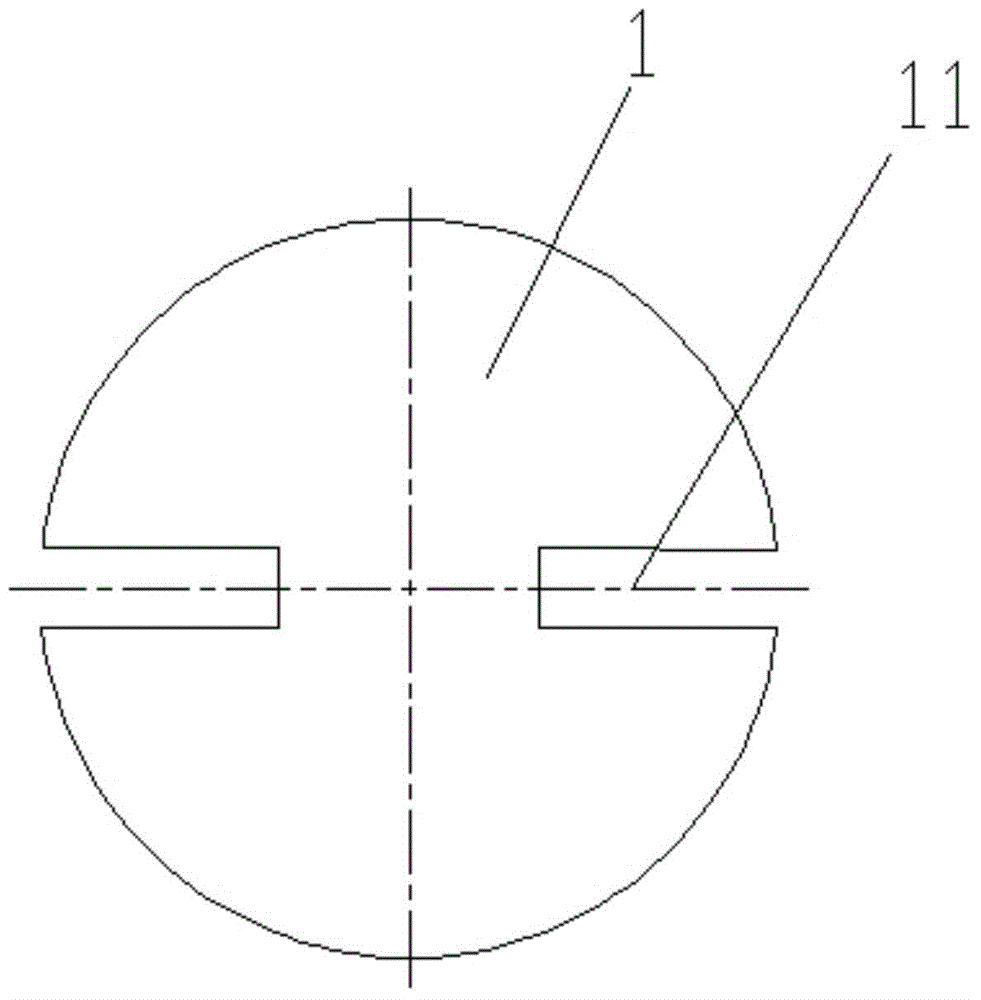

[0024] The milling mechanism includes a vertically arranged milling oil cylinder (61) and a milling platform (62) arranged below the milling oil cylinder. The milling platform is provided with a through hole. The milling platform is also provided with two milling heads (63). The holes are arranged axis-symmetrically.

[0025] The clamping mechanism is arranged under the milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com