Novel dross removal device

A new type of slag removal technology, applied in the direction of charge control, lighting and heating equipment, furnace components, etc., can solve the problems of affecting the quality of casting damage, short service life of slag removal plates, and prolonging slag removal time, so as to reduce operating failures and The consumption of slag scraping plate, prolonging the service life and improving the effect of slag scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

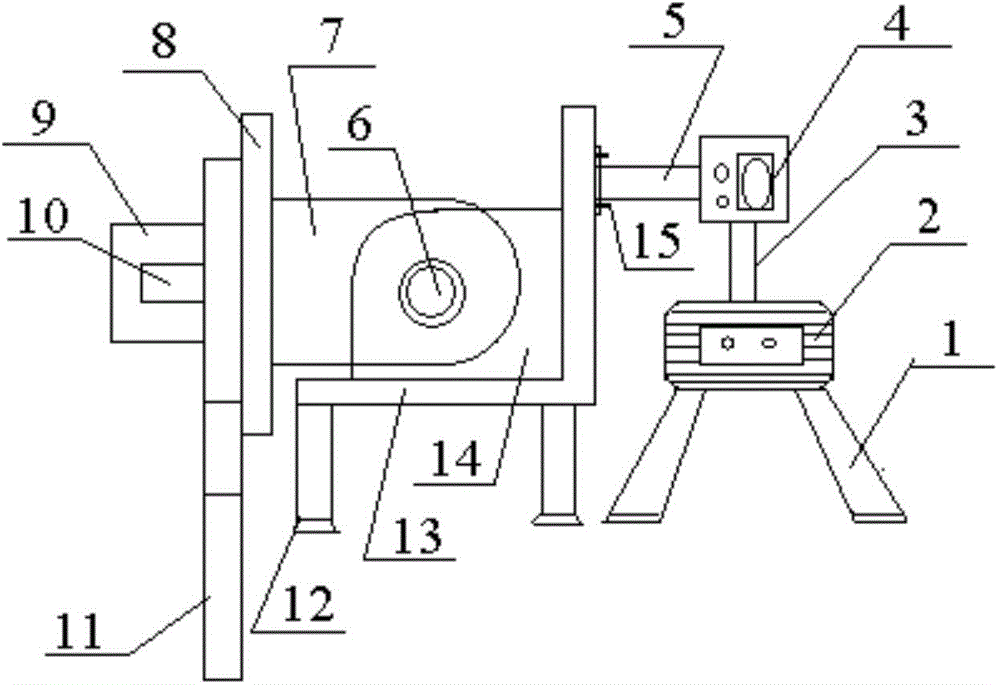

[0015] Attached below figure 1 The present invention will be further described with reference to specific embodiments.

[0016] The present invention provides a new type of slag removal device, which is characterized in that it includes a motor 2, a numerical control instrument 4, an "L"-shaped support 13 and a slag removal plate 11, and the motor 2 is connected to the numerical control instrument 4 The rod 3 is connected, the numerical control instrument 4 is connected with the "L"-shaped support 13 through the telescopic arm 5, which realizes the automation of the slag removal process, improves the slag removal efficiency, and reduces the labor intensity of the operator. The arm 5 and the "L"-shaped support 13 are fixed by a nut 15, and the "L"-shaped support 13 is welded with a single ear plate 14, and the single ear plate 14 is movable with the double ear plate through the hinge shaft 6 7, the double ear plate 7 is welded on the inner side of the stop plate 8, the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com