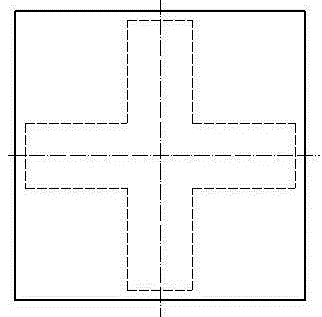

Free forging process for large cross forged pieces

A cross-shaped, forging technology, applied in the field of forging and forming of large forgings, can solve the problems of inability to guarantee, reduced mechanical properties, and increased machining time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as figure 1 as well as Figure 4 to Figure 7 As shown, a large-scale cross-shaped forging free forging process, the specific steps are as follows,

[0028] 1) Forge the steel ingot into a square forging billet (such as Figure 5 shown), the eight sides of the square forging billet are the first side, the second side, the third side, the fourth side, the fifth side, the sixth side, the seventh side and the eighth side;

[0029] 2) Two anvils (1 and 2) are used to forge the square forging billet, such as Figure 7 As shown, each anvil includes three working surfaces, and the three working surfaces are connected in sequence to form a "︺" shape arrangement. The two working surfaces on both sides are perpendicular to each other, and the dimensions of the three working surfaces in the thickness direction of the anvil Greater than the thickness of the octagonal forging billet,

[0030] Such as Figure 6 As shown, two anvils respectively forge the first side and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com