Pearl drilling and threading integrated device

A threading and pearl technology, applied in jewelry, clothing, applications, etc., can solve problems such as the inability to realize automatic threading, and achieve the effects of convenient threading, cost reduction, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] combine Figure 1-12 , to further illustrate the present invention:

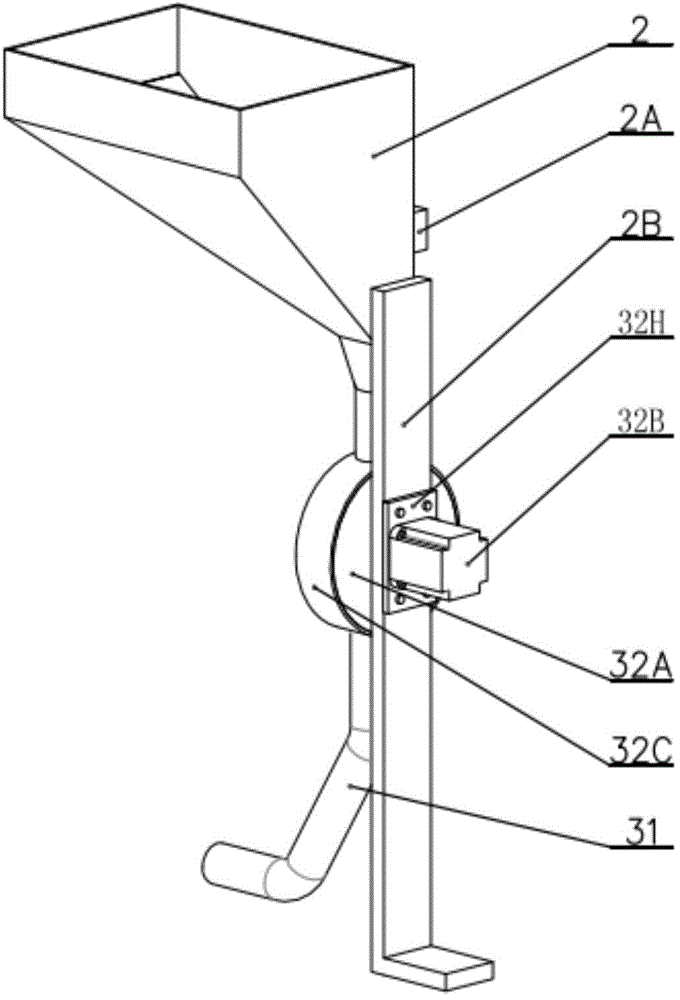

[0037] An integrated pearl drilling and threading device, comprising a frame 1, on which a hopper 2, a feeding mechanism, a clamping mechanism, a drilling mechanism and a threading mechanism are installed; 2B is fixed on rack 1;

[0038] The feeding mechanism is composed of a feeding pipe 31 that transports pearls from the hopper 2 to the clamping mechanism and a feeding piece 32 that only allows one pearl to pass through at a time. The feeding piece 32 is installed on the feeding pipe 31;

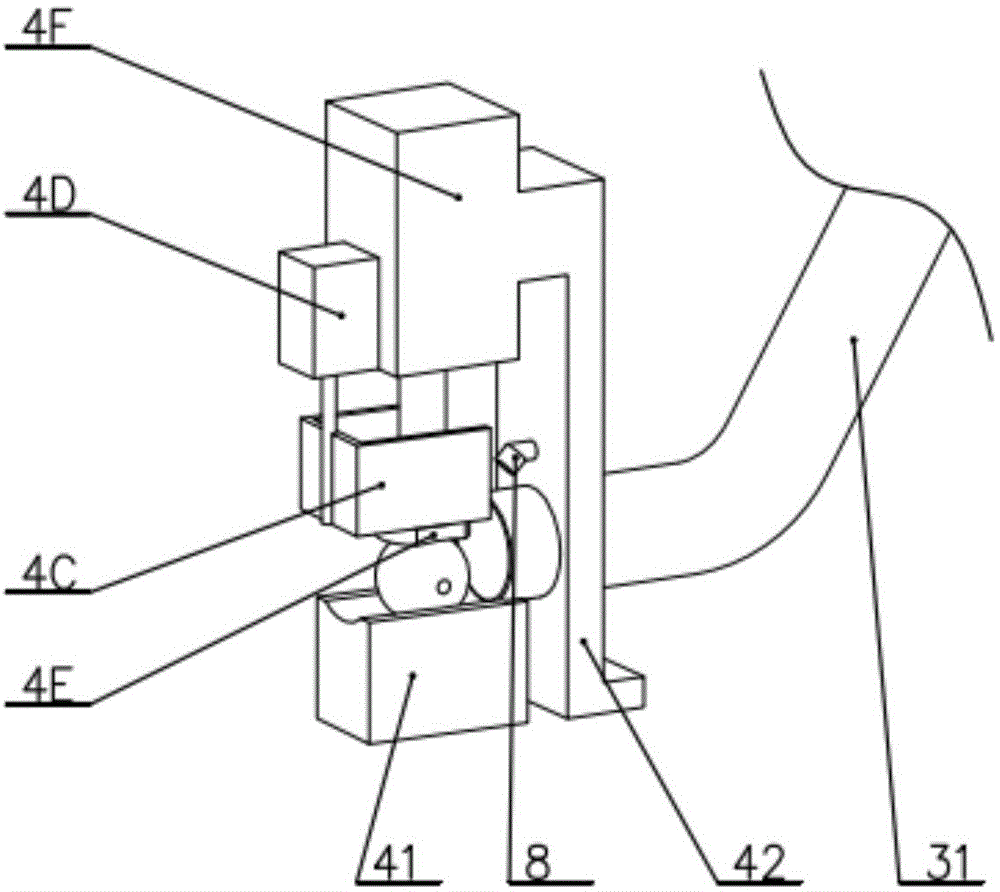

[0039]The clamping mechanism has a clamp seat for receiving the incoming material from the material guide tube 31. The clamp seat is provided with a feed port 4A connected with the material guide tube 31, a clamping station and a pearl outlet, and the clamping station includes positioning. The positioning nest 4B of the pearl 5 that is drilled and threaded, the baffle 4C and the baffle lifting mechanism 4D that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com