Online real-time measurement device and measuring method for sliver rejecting flow of cigarette making machine

A real-time measurement and measurement device technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems that the cigarette machine cannot remove the stem stick flow online, the measurement error is large, and the guidance is poor, so as to improve the reliability of the measurement results and improve the quality The effect of horizontal and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

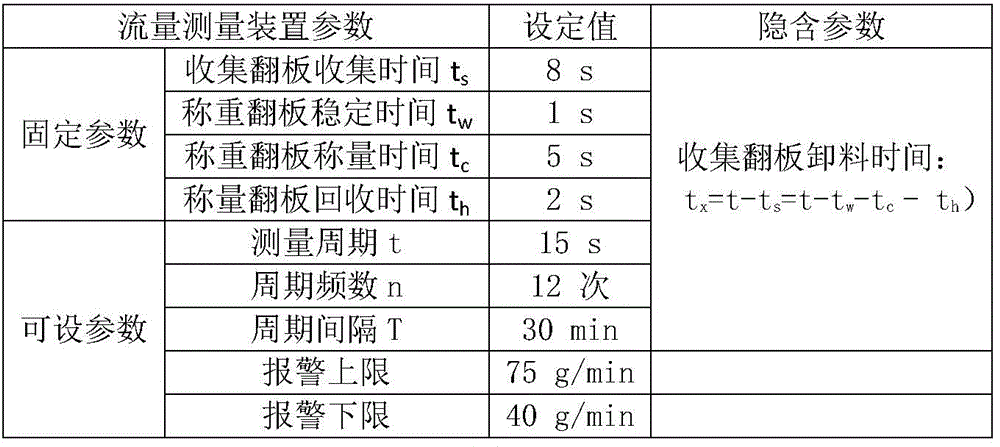

[0051] The device of the present invention will be further described below in conjunction with the accompanying drawings, attached tables and examples.

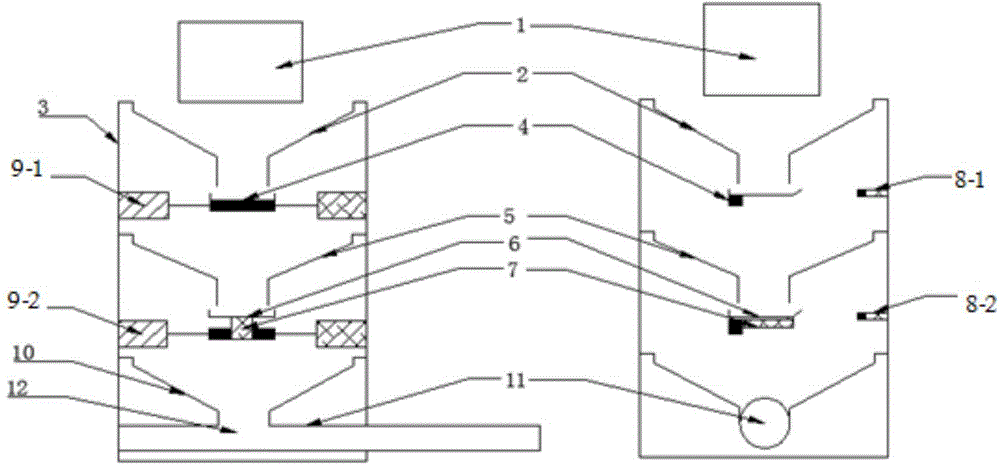

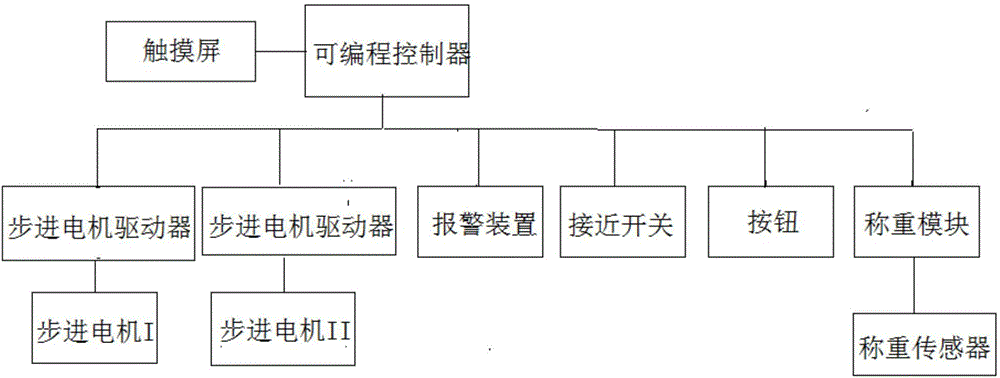

[0052] An on-line real-time measuring device for removing the stem sticks of a cigarette machine. It consists of a recovery mechanism, a control system, a data processing system and an information output system. Among them, the mechanical parts of the support, collection mechanism, weighing mechanism and recovery mechanism are as follows: figure 1 shown.

[0053] The support is a box with an upper opening, and four height-adjustable support feet are installed at the bottom; according to the needs of the device, a number of ventilation holes and installation holes are opened on the side wall of the box.

[0054] The collection mechanism includes a Y-shaped hopper I2, a dustpan-shaped collection flap I4, a proximity switch I8-1 and a stepping motor I9-1; the Y-shaped hopper I2 opens up and down, and the bottom communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com