Method of Processing Burley Tobacco by Alcoholization and Flavoring

A technology of burley tobacco and alcoholization, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems such as the method of processing and alcoholization of burley tobacco sheets, etc., and achieves improvement of internal quality and scope of use, simple and balanced operation process good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

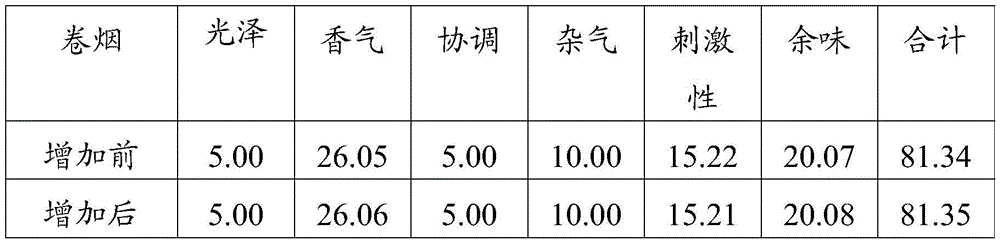

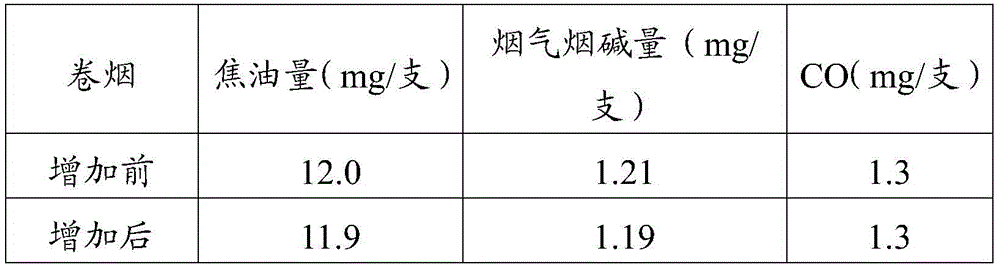

Embodiment 1

[0023] Select 100kg of Enshi's second-grade Burley tobacco flakes from the warehouse, fully soak them in 120kg of tap water; then weigh 3kg of peony flowers, pack them into 5 gauze bags, and then insert the gauze bags into the tobacco flakes Among them, boil for about 10 minutes; after cooling, drain the tobacco and fresh flowers, put them in an oven together, and dry them at a temperature of about 55°C. After cooling down and regaining moisture, keep the moisture content at 12-13%. Layered and stacked alternately, so that 5 gauze bags containing peony flowers are evenly placed in the cigarettes, packaged and aged for 15 to 18 months before entering the cigarette formula for use.

Embodiment 2

[0025] Select 80kg of Enshi's second-grade Burley tobacco slices from the warehouse, fully soak them in 120kg of tap water; then weigh 2.5kg of peony flowers, pack them into 3 gauze bags, and then insert the gauze bags into the slices In the smoke, boil for about 5 minutes; after cooling, drain the tobacco and flowers, put them in an oven together, and dry them at a temperature of about 55°C. After cooling down and regaining moisture, keep the moisture content at 12-13%. The leaves are alternately stacked in layers, so that three gauze bags containing peony flowers are evenly placed in the cigarettes, and they can be used in cigarette formulas after packaging and aging for 15 to 18 months.

Embodiment 3

[0027] Select 110kg of Enshi's second-grade Burley tobacco slices from the warehouse, fully soak them in 110kg of tap water; then weigh 3.5kg of peony flowers, pack them into 5 gauze bags, and then insert the gauze bags into the slices In the smoke, boil for about 15 minutes; after cooling, drain the tobacco and flowers, put them in an oven together, and dry them at a temperature of about 60°C. After cooling down and regaining moisture, keep the moisture content at 12-13%. The leaves are alternately stacked in layers, so that five gauze bags containing peony flowers are evenly placed in the cigarettes, and the packaged alcohols can be used in cigarette formulas after 15-18 months of aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com