Substrate etching method

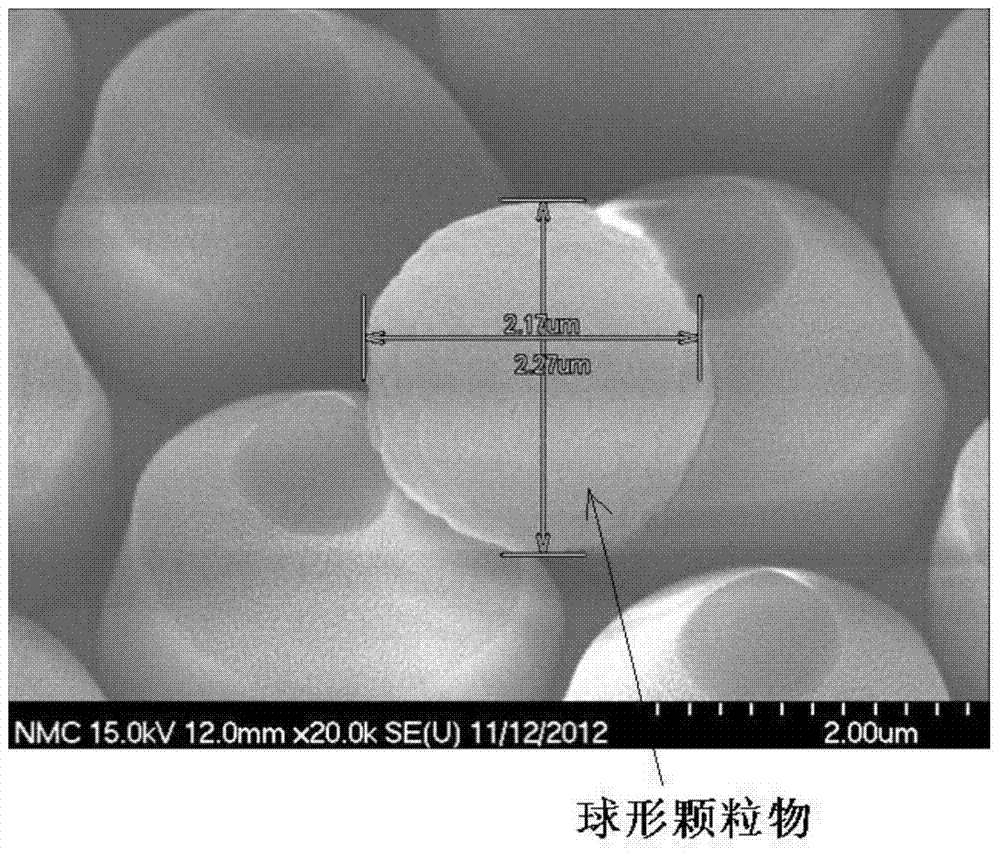

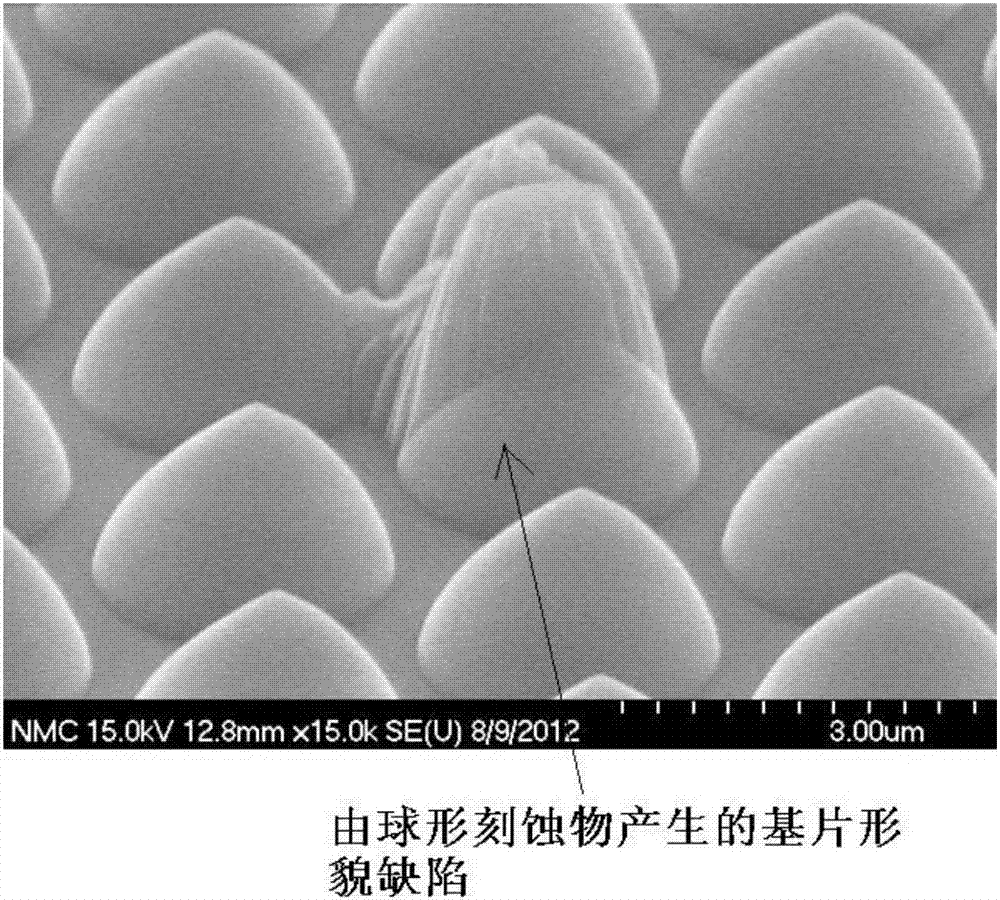

A substrate and main etching technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of shape defects, no cleaning effect, etc., and achieve the effect of reducing defects, reducing defects, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order for those skilled in the art to better understand the technical solution of the present invention, the substrate etching method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

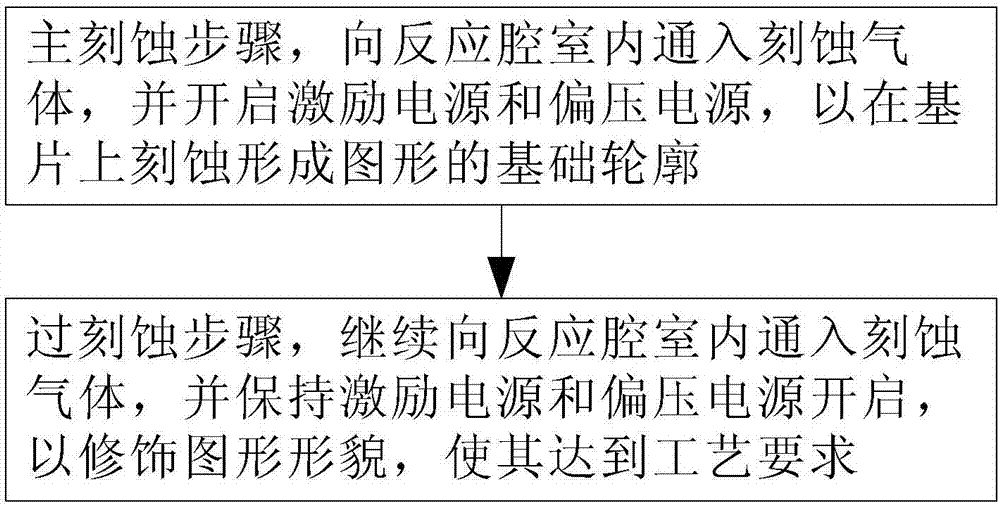

[0048] figure 2 A flowchart of a method for etching a substrate provided by an embodiment of the invention. see figure 2 , the substrate etching method comprises the following steps:

[0049] In the main etching step, the etching gas is introduced into the reaction chamber, and the excitation power supply and the bias power supply are turned on, so as to etch and form the basic outline of the pattern on the substrate;

[0050] After the etching step, continue to feed the etching gas into the reaction chamber, and keep the excitation power supply and the bias power supply turned on, so as to modify the shape of the pattern and make it meet the process requirements.

[0051] The principle of the substrate etching meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com