Medium-frequency heating calcinator

A calcination furnace and intermediate frequency technology, applied in the field of calcination furnace, can solve the problems of uneconomical price and economy, failure to meet environmental protection requirements, low product quality, etc., and achieve the effect of easy control, less impurities and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

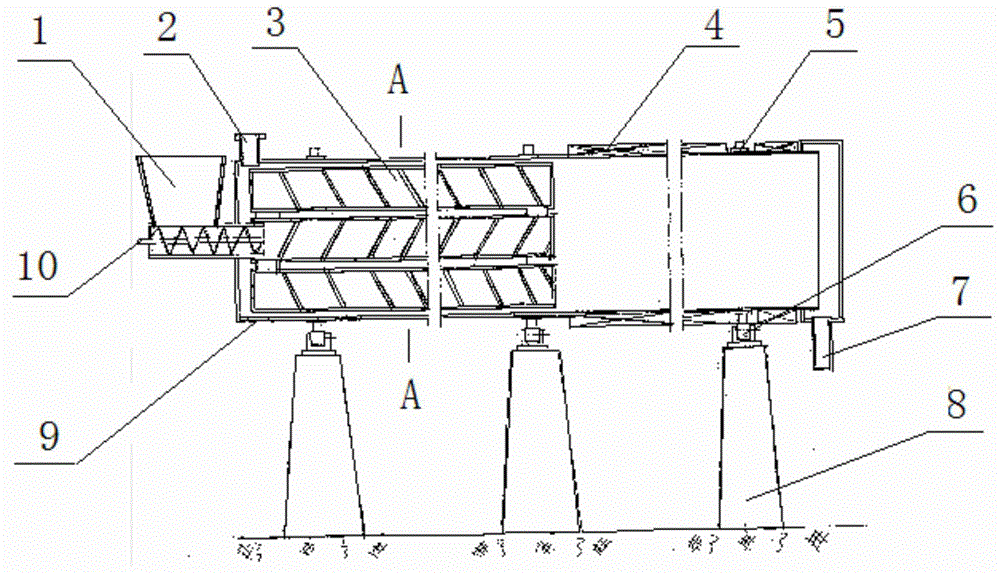

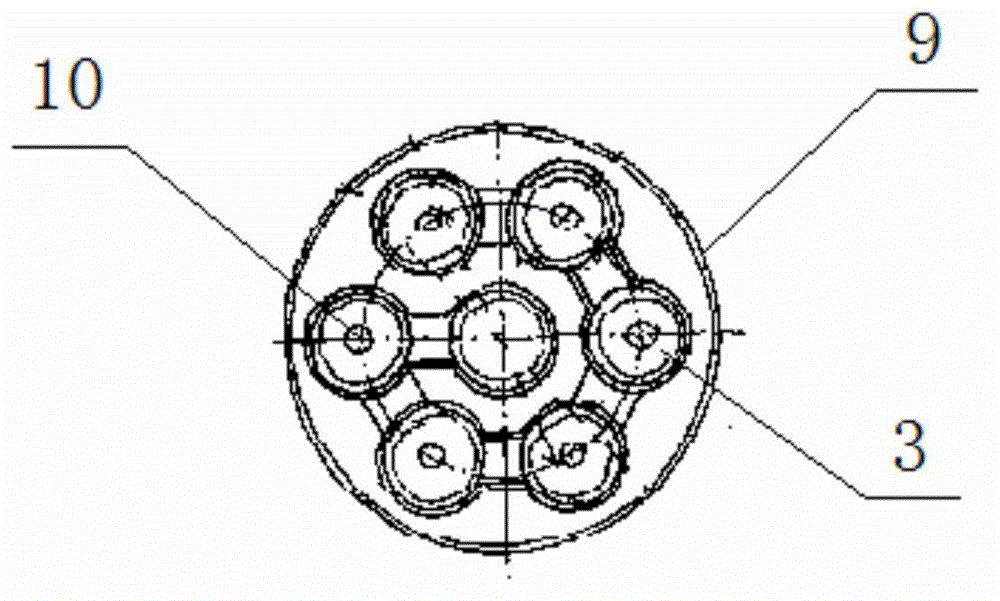

[0021] Such as figure 1 Shown, the present invention comprises furnace body 9, supporting mechanism, feeding mechanism 1, discharge bin 7, temperature control system and cooling system, wherein furnace body 9 is the rotator that is welded into after the iron plate with 8mm thickness is rounded, and It is arranged on the support mechanism, and the two ends of the furnace body 9 are respectively provided with a feed inlet and a discharge outlet, and the feed inlet is higher than the discharge outlet. Feeding mechanism 1 is arranged at the feeding port of one end of body of furnace 9, and discharge bin 7 is arranged at the discharging port of the other end of body of furnace; The hopper and the feed hopper are made of stainless steel. The screw feeder 10 is a direct-current speed control to control the feed speed, and the power of the feed motor is 1.1kw. The discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com