Tobacco Lifting Device

A technology for tobacco rods and lifting rods, which is applied in the directions of packaging, transportation packaging, transportation and packaging, can solve the problems of compression and deformation of the bottom tobacco rods, and achieves the advantages of avoiding the compression of the bottom tobacco rods, improving the running performance and improving the aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

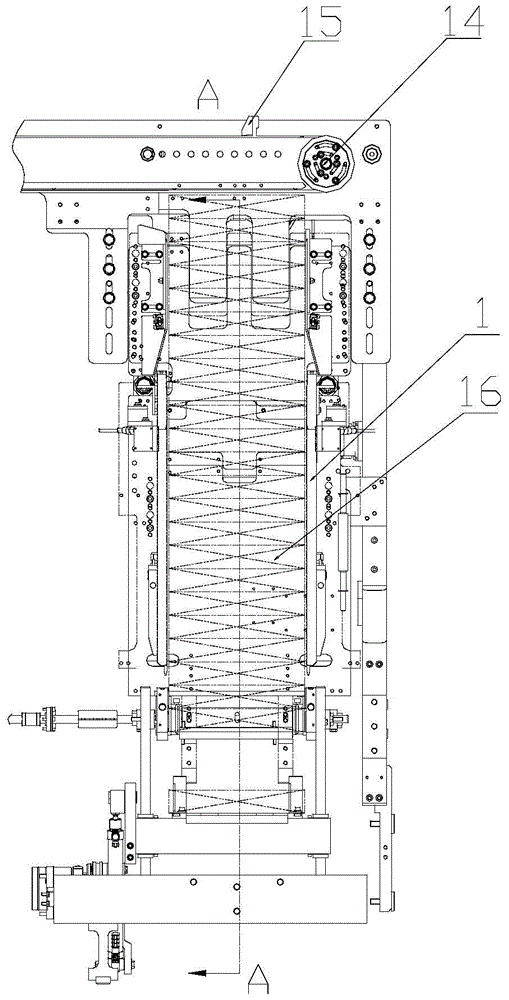

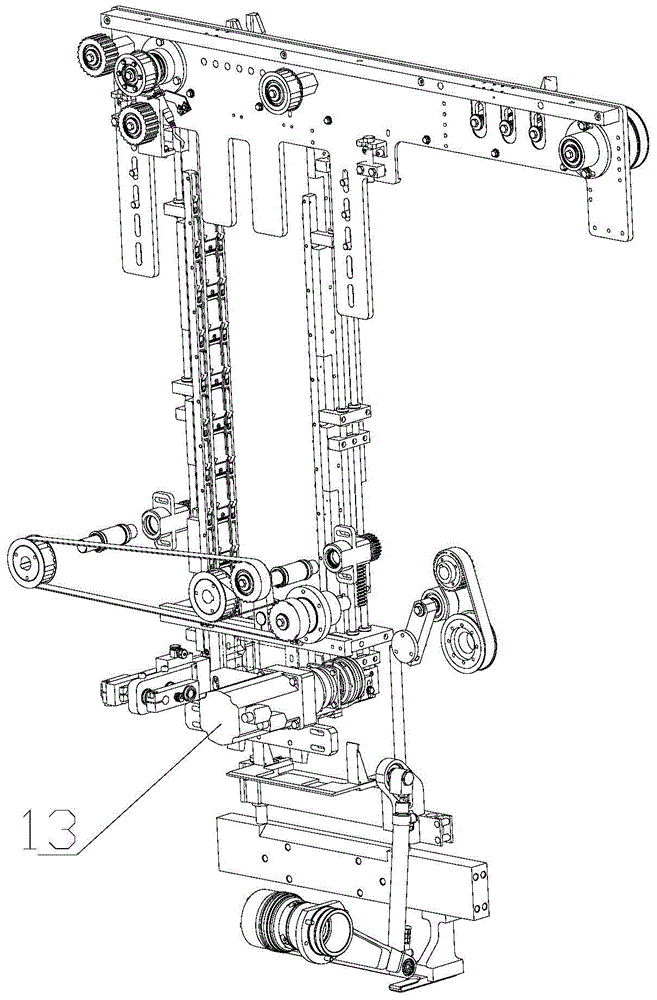

[0063]The invention provides a tobacco rod lifting device, which comprises two longitudinal fixed guide plates 1 oppositely arranged, and a tobacco rod lifting channel is formed between the two fixed guide plates 1 . Both sides of each fixed guide plate 1 are respectively provided with a movable guide bar 21 to form a movable guide plate 2 , and the movable guide plate 2 moves up and down relative to the fixed guide plate 1 . The back side of the fixed guide plate 1 is provided with a guide rail 9, on which a plurality of connecting plates 10 are pierced, and the movable guide bar 21 is fixed on the connecting plate 10, and the movable guide plate 2 is driven by a transmission system to move up and down along the guide rail 9, and the transmission system is as follows: image 3 , Figure 5 and Figure 6 As shown, the servo motor 13 (that is, the power source) is fixed on the mounting frame through the flange, and the servo motor 13 drives the gear 12 to rotate through the syn...

Embodiment 2

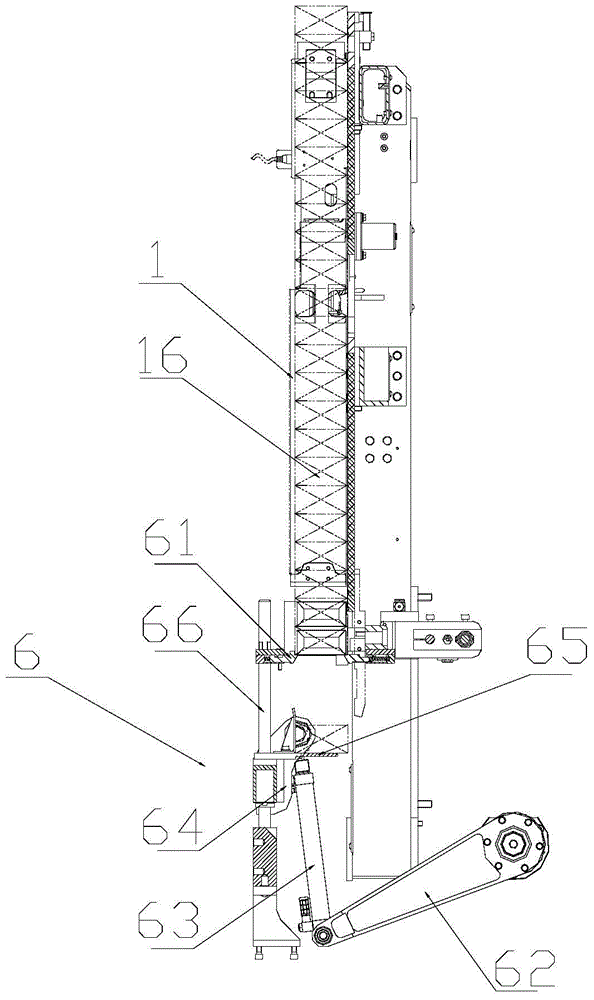

[0067] In the present invention, the tobacco rod is pushed into the lifting channel through the tobacco rod pushing mechanism 6 provided under the fixed guide plate. The tobacco rod pushing mechanism 6 includes a swing rod 62, a sliding frame 64, and a cylinder 63 connecting the swing rod 62 and the sliding frame 64. 1. A cigarette pushing plate 65 that slides along the slide rail 66 on the sliding frame 64 and a support plate 61 located on the front and rear sides of the lifting passage. The support plate 61 is also provided with a storage chamber, and a third cigarette holder is provided in the storage cavity. Plate 43, the third cigarette holder plate 43 has the same structure as the first cigarette holder board 41 and the second cigarette holder board 42, and also has a cigarette holder part 5 that can protrude or retract into the accommodating cavity, only the direction of installation is different, The first tobacco holder 41 and the second cigarette holder 42 are positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com