Organic light emitting diode device encapsulation drying agent and encapsulation application method thereof

A light-emitting diode and device packaging technology, which is applied in the fields of organic light-emitting devices, organic light-emitting device structures, organic light-emitting device manufacturing/processing, etc., can solve the problems of high manufacturing cost, complicated process, low moisture absorption rate of calcium oxide, etc., and achieve cheap raw materials , increase specific surface area, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

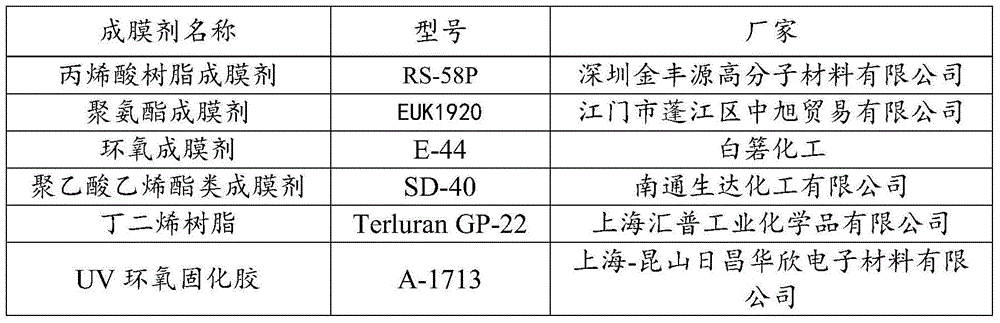

[0025] In a preferred embodiment of the present invention, the present invention provides a method for preparing a desiccant for encapsulating OLED devices. An oxide film is coated on the OLED encapsulating cover plate by a simple spin coating method, and then baked at a low temperature. Dry to obtain a desiccant layer. The desiccant film is prepared as a desiccant coating solution by using calcium oxide microcrystals, calcium chloride and a film-forming agent, and then is coated on the inner layer of the package cover by spin coating. The thickness of the desiccant film is 2-10 μm. In the present invention, the film thickness refers to the thickness of a coating film formed after coating the coating liquid on the device and drying it.

[0026] Compared with traditional drying sheets, this method is simple to operate, easy to prepare, cheap and easy to obtain raw materials, convenient to store, and good in stability. Compared with other thin film desiccants, the coating liqui...

Embodiment 1

[0033] Take 5g of calcium chloride and 20g of emulsion-type epoxy film-forming agent, mix well, dissolve in acetone to form a saturated solution of calcium chloride, mix well, add calcium oxide microcrystals with a particle size of 0.1-0.5μm , and make the molar ratio of chloride and calcium oxide in the coating solution to be 1:7, and repeatedly apply the coating solution to the inner layer of the OLED cover plate through a glue leveler, and obtain a 5 μm thick desiccant layer after drying. Put the desiccant cover into the drying oven and dry at 100°C for 15 minutes.

Embodiment 2

[0035] Take 7g of magnesium chloride and 20g of acrylic resin film-forming agent, mix well, dissolve in ethanol to form a saturated solution of magnesium chloride, mix well, add calcium oxide microcrystals with a particle size of 0.1-0.5μm, and make the coating solution The molar ratio of chloride to calcium oxide is 1:5, and the coating liquid is repeatedly coated on the inner layer of the OLED cover through a glue leveler, and after drying, a 3 μm thick desiccant layer is obtained, and the cover coated with the desiccant is placed Put into a drying oven and dry at 100°C for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com