Mosaic exposure method for color filter

A color filter and a technology for increasing exposure, applied in the field of splicing exposure in color filters, can solve problems such as dislocation or fault, unable to achieve 1shot exposure, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

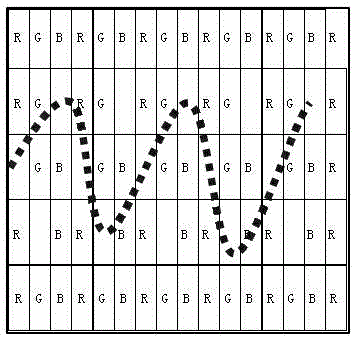

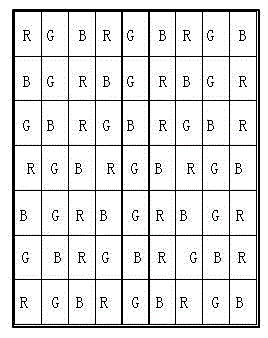

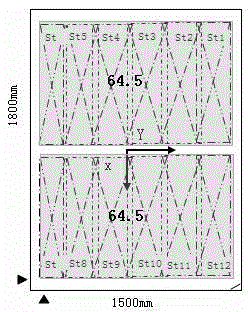

[0023] A method for splicing exposure in a color filter, comprising the steps of:

[0024] First of all, the splicing exposure needs to make alignment marks and splicing marks in the first process of the color filter BM process. The difference from the ordinary Step exposure method is that the splicing exposure needs to be done in order to avoid disconnection at the splicing place. The spliced area is the public area exposed on both sides, that is, the spliced area will be exposed twice on both sides, so the number of exposure shots will increase. If the three primary colors of RGB are arranged in Stripe, because of the splicing MURA of RG B It is necessary to use different alignment marks for RGB, so the number of shots in the BM process will be more than 10 shots.

[0025] Secondly, the splicing exposure in the RGB process must be exposed according to the alignment mark of the BM process. In order to confirm the splicing accuracy, it is necessary to confirm the alignment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com