Transmission line protective device

A protection device and transmission line technology, applied in overhead installation, cable installation, optical fiber/cable installation, etc., can solve the problems of falling off protection steel strands, optical cables, etc., avoid repeated replacement, good waterproof performance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

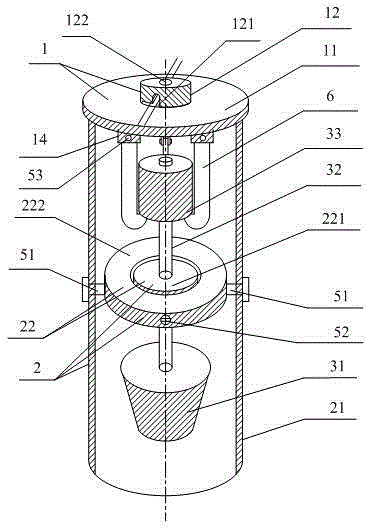

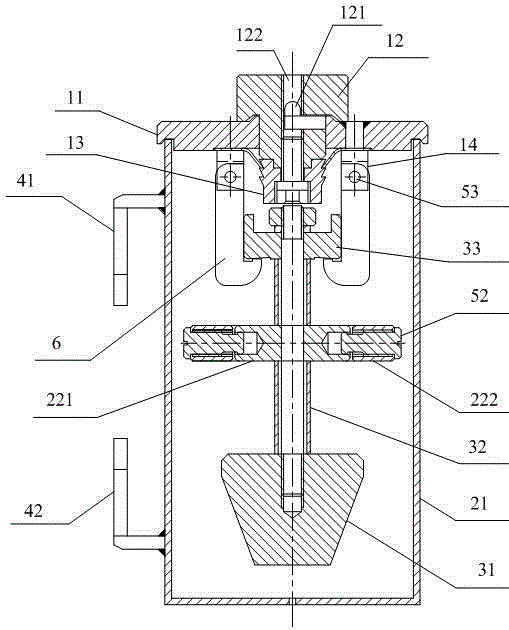

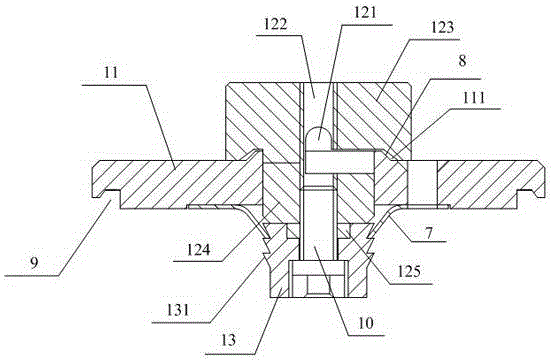

[0032] Such as figure 1 As shown, a transmission line protection device includes a steel strand splint 1 for fixing the steel strand, a disconnector base 2, and a positioning pendant assembly suspended at the lower end of the steel strand splint 1 .

[0033] The disconnector base 2 includes a cylindrical hollow body 21 and a universal rotation mechanism 22 arranged in the hollow body 21; the upper end of the hollow body 21 is in contact with the lower surface of the steel strand splint 1, and the lower end is closed However, drainage holes or drainage grooves are reserved;

[0034] The universal rotation mechanism 22 is partly connected to the central cylinder 21 and partly connected to the positioning suspension hammer assembly, which is configured to keep the positioning suspension hammer assembly in a vertical state when the central cylinder 1 is tilted at any state.

[0035] When in use, the hollow cylinder 21 is vertically fixed on the pole, the steel strand splint 1 is ...

Embodiment 2

[0038] On the basis of Embodiment 1, in this embodiment, the lower end of the steel strand splint 1 is also hinged with a plurality of hooks 6, and the hooks 6 can move in a direction consistent with the radial direction of the hollow cylinder 21, that is, its When moving, the lower end moves towards the central axis of the hollow cylinder 21 or away from the central axis of the hollow cylinder 21;

[0039] The positioning suspension hammer assembly includes a suspension hammer arm 32, a suspension mechanism 33 connected to the upper end of the suspension hammer arm 32, and a gravity suspension hammer 31 fixed at the lower end of the suspension hammer arm 32; the suspension mechanism 33 is suspended on the hook 6, and a plurality of The hooks 6 are evenly distributed on the side of the suspension mechanism 33, and hook the suspension mechanism 33 from different directions. In this embodiment, the suspension mechanism 33 is a cylindrical mechanism with a vertical axis. In pract...

Embodiment 3

[0043] On the basis of Embodiment 2, in this embodiment, the universal rotating mechanism 22 is further improved, and the universal rotating mechanism 22 includes a first turntable 221 arranged inside the hollow cylinder 21, and a first turntable 221 arranged outside the first turntable 221. The annular second turntable 222 of. The inner diameter of the second turntable 222 is larger than the radius of the first turntable 221. The second turntable 222 is sheathed outside the first turntable 221, and its inner peripheral surface faces the first turntable 221. The central axes of the two turntables coincide.

[0044] Both sides of the second turntable 222 are respectively connected to the hollow cylinder 21 by a fastener A51, and both sides of the first turntable 221 are respectively connected to the second turntable 222 by a fastener B52. In this embodiment The fastener A51 and the fastener B52 use bolts, and other commonly used fasteners, such as but not limited to pin shafts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com