Measuring device for rigidity of rubber bushings and usage method thereof

A technology of rubber bushing and measuring device, which is applied in measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as measuring single stiffness, achieve high versatility, data reading and processing Convenience and the effect of improving the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

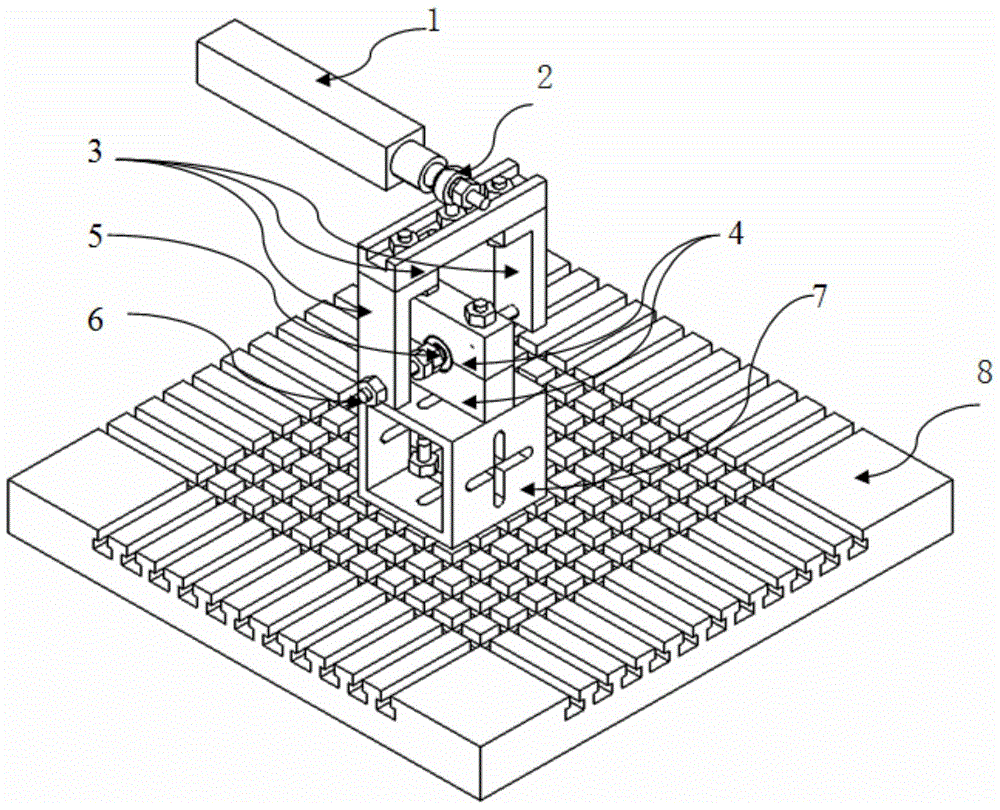

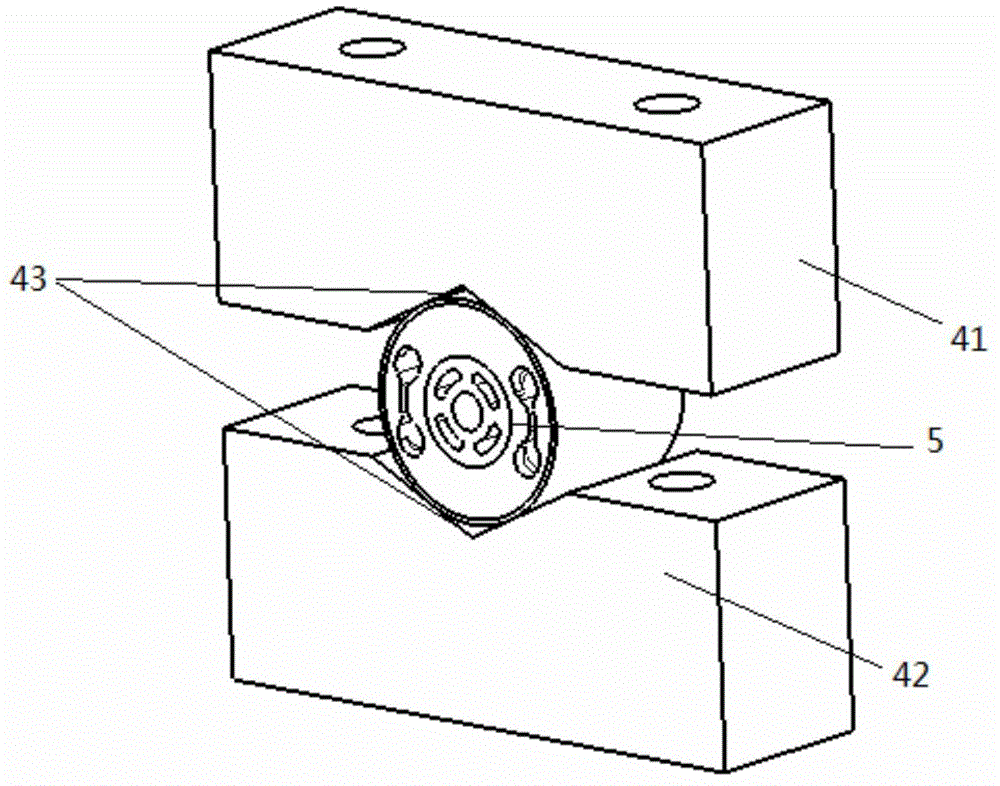

[0025] Examples such as Figures 2 to 5 As shown, a rubber bush stiffness measuring device includes a workbench 8, a connecting support 7 fixed on the workbench 8, and a lower fixing bracket assembly 4 for fixing the rubber bush 5; a dynamic tester is also provided 1. The connecting shaft 6 passing through the inner ring of the rubber bush 5, and the upper fixing bracket assembly 3 fixedly connected to both ends of the connecting shaft 6, the working end of the dynamic tester 1 is used for connecting the upper fixing bracket assembly 3 Apply force to the upper fixing bracket assembly 3.

[0026] A ball joint 2 for connection is provided between the upper fixing bracket assembly 3 and the working end of the dynamic tester 1 . The upper fixing bracket assembly 3 includes a vertical plate 31 fixedly connected to the connecting shaft 6, a crossbeam 32 arranged between the two vertical plates 31, the crossbeam 32 and the vertical plate 31 are connected by bolts, and the bolts on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com