Hauling part for chain hauled shearer

A technology of traction unit and coal shearer, which is applied in the direction of earthwork drilling, slitting machinery, and propulsion, can solve the problems of high machine surface height, poor adaptability, complex structure, etc., and achieve the goal of reducing thickness and ensuring coal passing space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

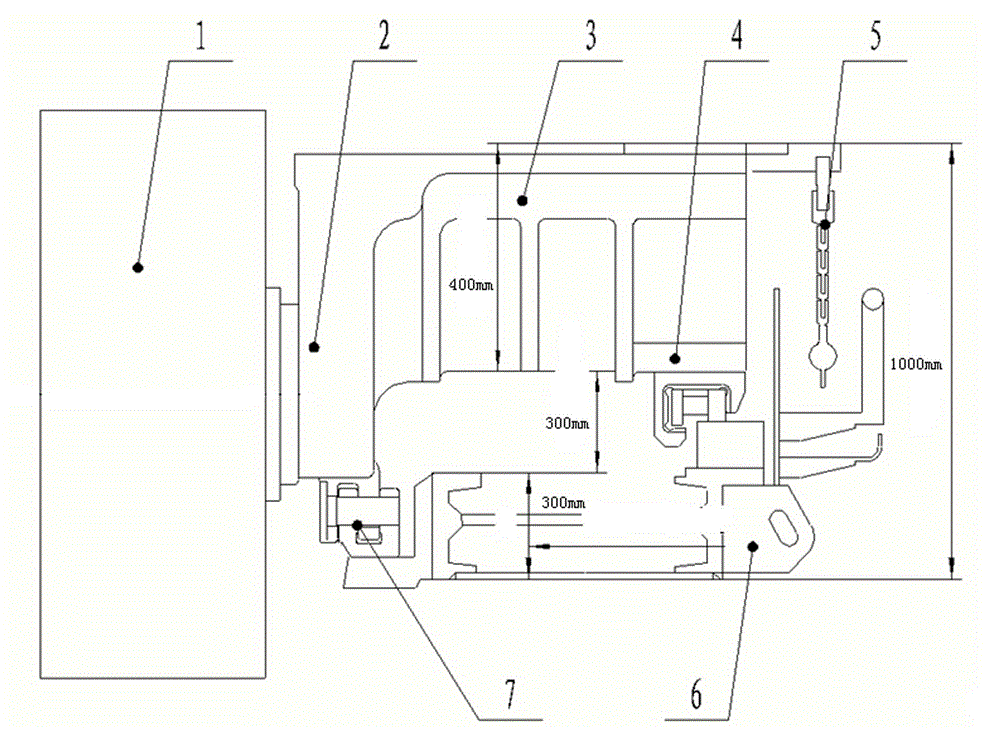

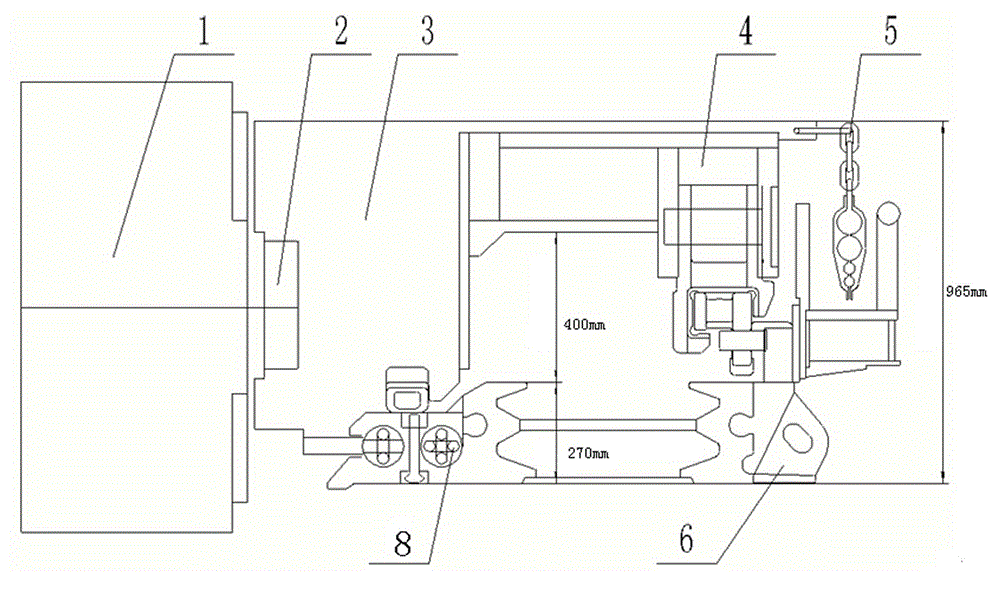

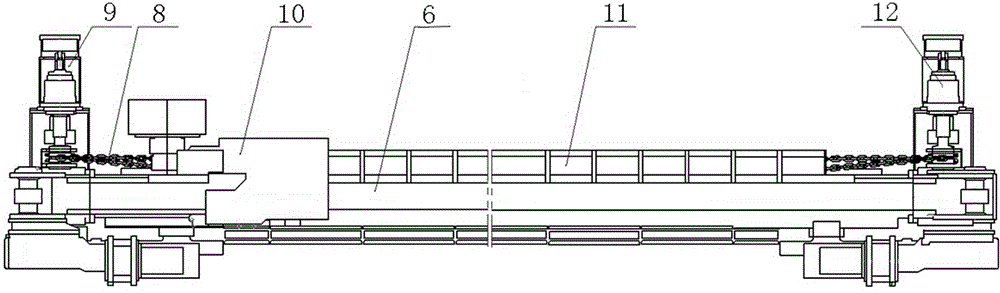

[0012] A traction part for a chain traction coal shearer, comprising a nose traction part 9 and a tail traction part 12, the nose traction part 9 and the tail traction part 12 are respectively installed on the nose frame and the tail frame of the scraper conveyor 6 Above, the nose traction part 9 and the tail traction part 12 both include a traction motor 13, the traction motor 13 is connected with a reducer 16 fixed in the cover tube 15 through a coupling 12, and the reducer 16 is connected through a pin coupling 17 A sprocket 18 is connected, and the traction chain 8 located in the chainway 11 of the scraper conveyor 6 is wound on the sprocket 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com