Adhesive for iodine polarizer, preparation method of adhesive and iodine polarizer

A technology for adhesives and polarizers, applied in the direction of monocarboxylate copolymer adhesives, adhesives, polarizing elements, etc., can solve the problems that the performance of iodine-based polarizers does not meet the requirements of electronic products, so as to improve optical performance and application The effect of range extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

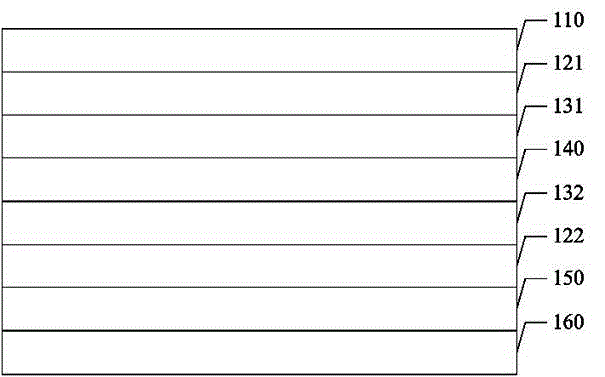

Image

Examples

Embodiment 1

[0049] Formula of two adhesive layers in iodine-based polarizer:

[0050] The adhesive formulation of the first adhesive layer is (by weight): 1.9% of JV company’s J-type adhesive raw material; pure water 97%; H 3 BO 3 0.4%; Ethylene Glycol: 0.3%; Glyoxal: 0.3%; Exp 0.1%; The viscosity of the adhesive formulated according to the content of the above components is 11-14cps.

[0051] The adhesive formulation of the second adhesive layer is (by weight): 1.9% of JV company’s J-type adhesive raw material; 97% of pure water; H 3 BO 3 0.4%; Ethylene Glycol 0.3%; Glyoxal 0.3%; Exp 0.1%; The viscosity of the prepared adhesive is 11-14cps.

Embodiment 2

[0053] Formula of two adhesive layers in iodine-based polarizer:

[0054]The adhesive formulation of the first adhesive layer is (by weight): 3.5% of the J-type adhesive material of JV Company; 95% of pure water; H 3 BO 3 0.4%; ethylene glycol 0.3%; glyoxal 0.3%; Exp 0.5%, the viscosity of the prepared adhesive is 13-18cps.

[0055] The adhesive formulation of the second adhesive layer is (by weight): 3.5% of the J-type adhesive raw material of JV Company; 95% of pure water; 3 BO 3 0.4%; Ethylene Glycol 0.3%; Glyoxal 0.3%; Exp 0.5%; The viscosity of the prepared adhesive is 13-18cps.

Embodiment 3

[0057] Formula of two adhesive layers in iodine-based polarizer:

[0058] The adhesive formula of the first adhesive layer is (by weight): 7% of the J-type adhesive material of JV Company, 91% of pure water, H 3 BO 3 : 0.2%, ethylene glycol: 0.2%, glyoxal: 0.1%, Exp: 1.5%, the viscosity of the adhesive after preparation is 35-43cps.

[0059] The adhesive formula of the second adhesive layer is (by weight): 7% of the J-type adhesive material of JV Company, 91% of pure water, H 3 BO 3 : 0.2%, ethylene glycol: 0.2%, glyoxal: 0.1%, Exp: 1.5%, the viscosity after preparation is 35-43cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com