Two-dimensional nonlinear vibration-isolating suspension frame of seats of off-road vehicle

An off-highway vehicle, non-linear technology, applied in vehicle seats, seat suspensions, vehicle components, etc., to achieve the effects of low cost, high reliability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

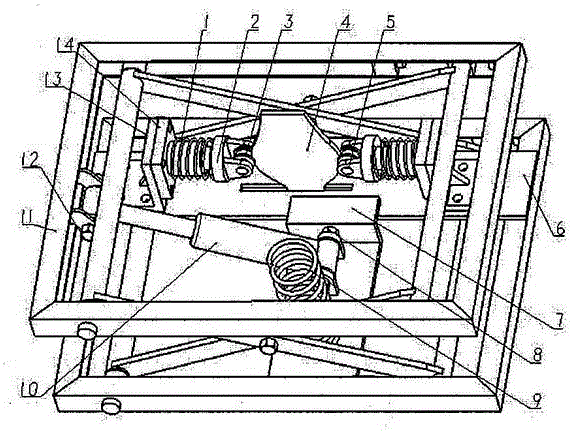

[0031] This embodiment is composed of a vertical vibration isolation part and a front and rear vibration isolation part. The vertical vibration isolation part and the front and rear vibration isolation parts play the role of vibration isolation in the vertical direction and the front and rear directions respectively. The two parts are fixed by bolts, such as figure 1 Shown; In this first embodiment, the vibration isolation part in the vertical direction is on the bottom, and the vibration isolation part in the front and rear direction is on the top.

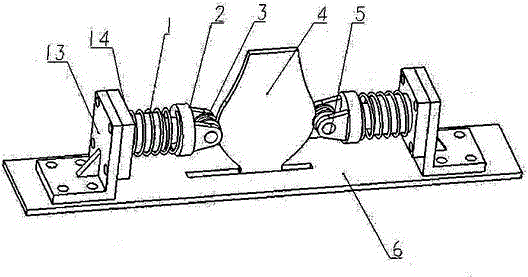

[0032] Such as figure 2 As shown, the vertical vibration isolation part is composed of scissor suspension 11, main spring 9, folded plate 7, damper 10, first damper pin 8, second damper pin 12 and symmetrically arranged It consists of two sets of negative stiffness spring mechanisms; image 3 As shown, the negative stiffness spring mechanism includes a negative spring 1, a negative spring guide column 2, a negative spring guide...

no. 2 example

[0039] Such as Figure 8 As shown, the difference between the second embodiment and the first embodiment is that the position of the horizontal spring 23 of the upper front and rear vibration isolation parts is changed. In the first embodiment, the horizontal spring 23 is located on the outside; in the second embodiment, The horizontal spring 23 is located on the inner side. Such as Figure 9 As shown, the connections of the second embodiment are the same as those of the first embodiment.

no. 3 example

[0041] Such as Figure 10 As shown, the difference between the third embodiment and the first embodiment is that the positions of the vertical vibration isolation part and the front and rear vibration isolation parts are changed. In the first embodiment, the vertical vibration isolation part is at the bottom, and the front and rear vibration isolation parts are at the bottom. above; in the third embodiment, the vertical vibration isolation part is on the top, and the front and rear vibration isolation parts are on the bottom. The connections in the third embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com